A new and old bridge joint structure system and construction method

A splicing seam and system technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as obstacles to vehicle wheel changes, bridge deck height difference, damage, etc., to increase friction coefficient, excellent water release performance, and avoid slipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

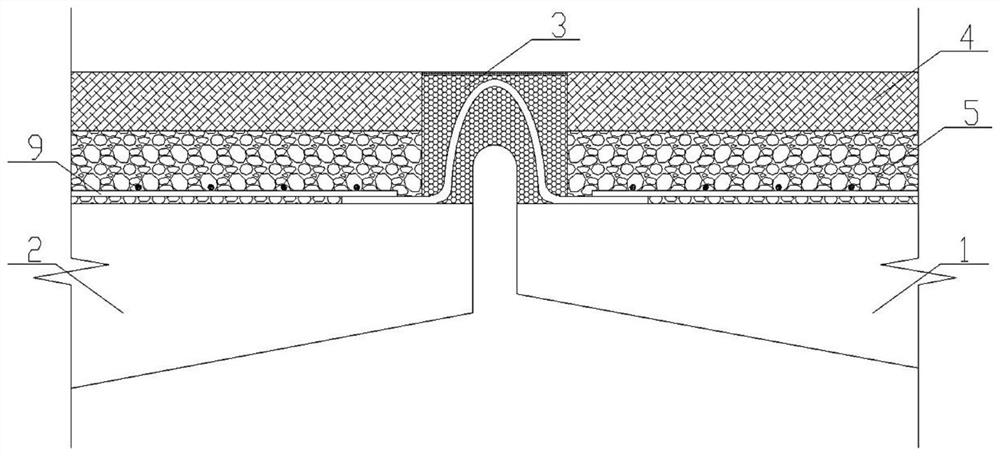

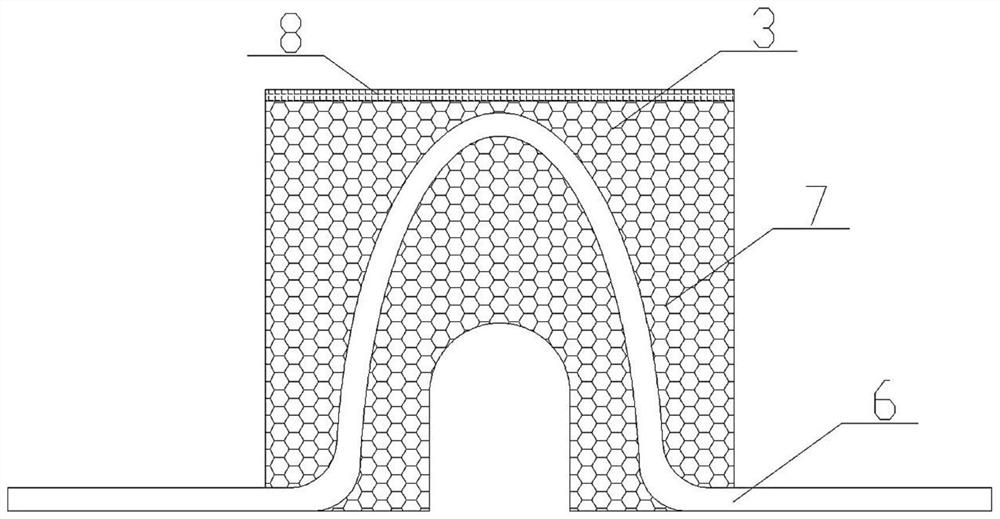

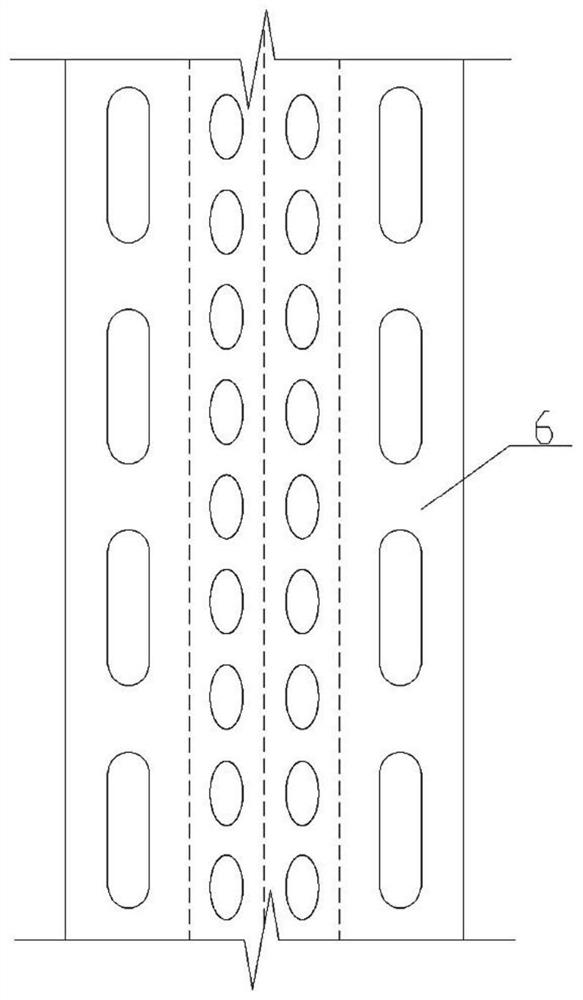

[0022] like figure 1 As shown, a kind of joint structure system of new and old bridges proposed by the present invention mainly includes new and old bridge decks, joint components, asphalt concrete surface course and reinforced concrete pavement, and the joint components include arched Porous steel plate connectors, and the middle part is pre-embedded in a rectangular polyurea elastomer, the upper surface is sprayed with a polyurea wear-resistant layer, and the porous steel plates on both sides are exposed. The porous steel plates on both sides of the splicing joint are welded to the extended steel bars of the bridge deck of the old and new bridges, and the micro-expansion steel fiber rapid-hardening sulfoaluminate cement concrete is poured on the welded joints, and finally the bridge deck asphalt concrete is paved together with the bridge deck of the old and new bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com