Power chip crimping packaging structure and manufacturing method thereof

A packaging structure and power chip technology, which is applied in the fields of printed circuit manufacturing, semiconductor/solid-state device manufacturing, printed circuit assembly of electrical components, etc., can solve problems such as high turn-off speed of unsuitable power chips, achieve low loss and eliminate parasitic parameter, the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

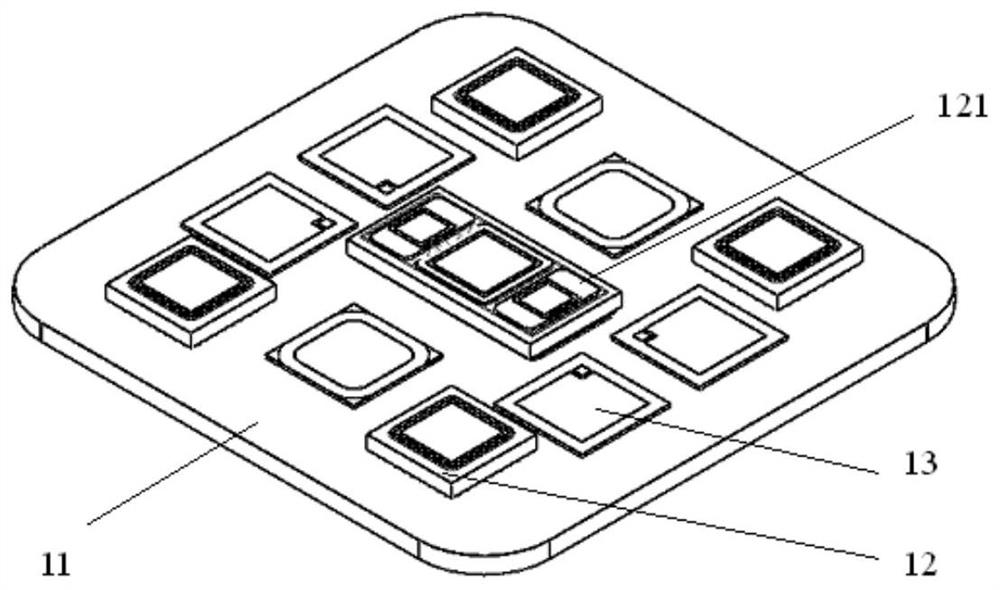

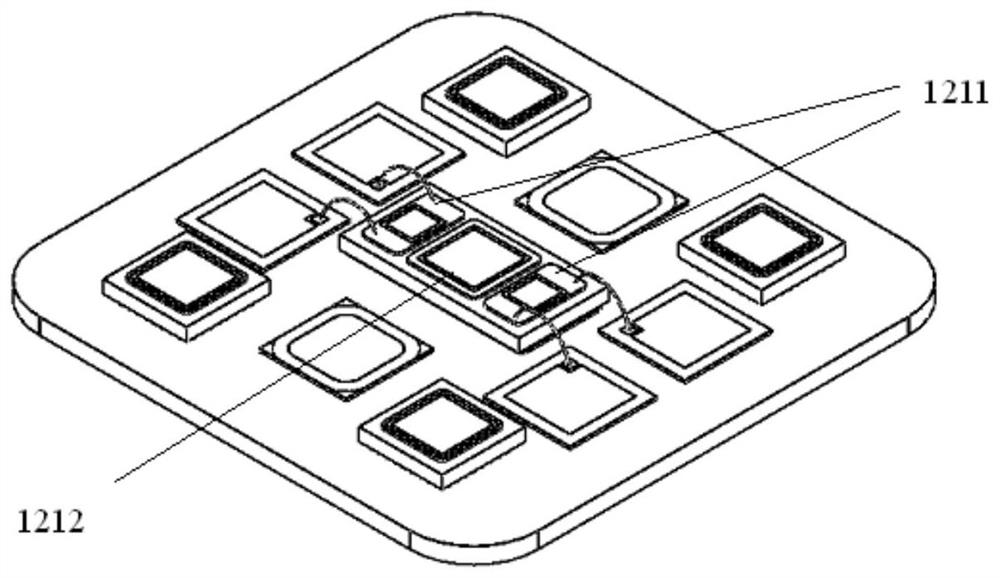

[0040] refer to Figure 1-Figure 10 , this embodiment provides a power chip crimping package structure, including:

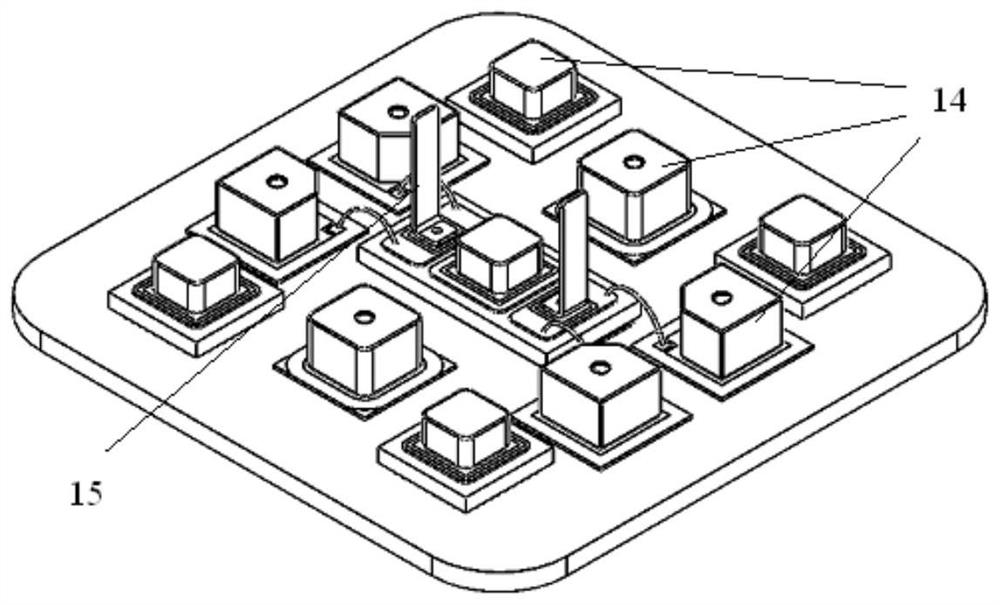

[0041] Base plate 11; multiple IGBT chips 13 and multiple copper-clad ceramic plates 12 are arranged on the base plate 11; each IGBT chip 13 is electrically connected to the copper-clad ceramic plate 12; each IGBT chip 13 and each copper-clad ceramic plate 12 are provided with There are metal pillars 14, and the top surfaces of each metal pillar 14 are located on the same horizontal plane. The material of the metal pillar 14 may be molybdenum-copper alloy or other thermally and electrically conductive metals with a thermal expansion coefficient close to that of the IGBT chip 13 .

[0042] The flexible metal plate 16 , the bottom surface of the flexible metal plate 16 covers and contacts the top surface of each metal column 14 .

[0043] The multi-layer PCB board 18, the multi-layer PCB board 18 is located above the flexible metal plate 16, and the multi-layer ...

Embodiment 2

[0062] refer to Figure 1-Figure 10 , the present embodiment provides a method for manufacturing a power chip crimping package structure, including the following steps:

[0063] refer to figure 1 , providing a bottom plate 11;

[0064] refer to figure 2 , welding a plurality of IGBT chips 13 and a plurality of copper-clad ceramic plates 12 on the base plate 11; each IGBT chip 13 is electrically connected to the copper-clad ceramic plate 12;

[0065] refer to image 3 , metal pillars 14 are formed on each IGBT chip 13 and each copper-clad ceramic plate 12, and the top surfaces of each metal pillar 14 are located on the same horizontal plane;

[0066] refer to Figure 4 , the flexible metal plate 16 is set, the bottom surface of the flexible metal plate 16 covers and contacts the top surface of each metal column 14; a plurality of auxiliary emitter lead-out terminals 161 are set on the top surface of the flexible metal plate 16;

[0067] refer to Image 6 , the multilay...

Embodiment 3

[0074] refer to Figure 11-Figure 20 , this embodiment provides another power chip crimping package structure, including:

[0075] Base plate 21; multiple IGBT chips 231 and multiple copper-clad ceramic plates 22 are arranged on the base plate 21; each IGBT chip 231 is electrically connected to the copper-clad ceramic plate 22; each IGBT chip 231 and each copper-clad ceramic plate 22 are provided with There are metal pillars 24, and the top surfaces of each metal pillar 24 are located on the same horizontal plane. The material of the metal pillar 24 may be molybdenum-copper alloy or other thermally and electrically conductive metals with a thermal expansion coefficient close to that of the IGBT chip 231 .

[0076] The flexible metal plate 26 , the bottom surface of the flexible metal plate 26 covers and contacts the top surface of each metal post 24 .

[0077] The multilayer PCB board 28 , the multilayer PCB board 28 is located above the flexible metal plate 26 , and the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com