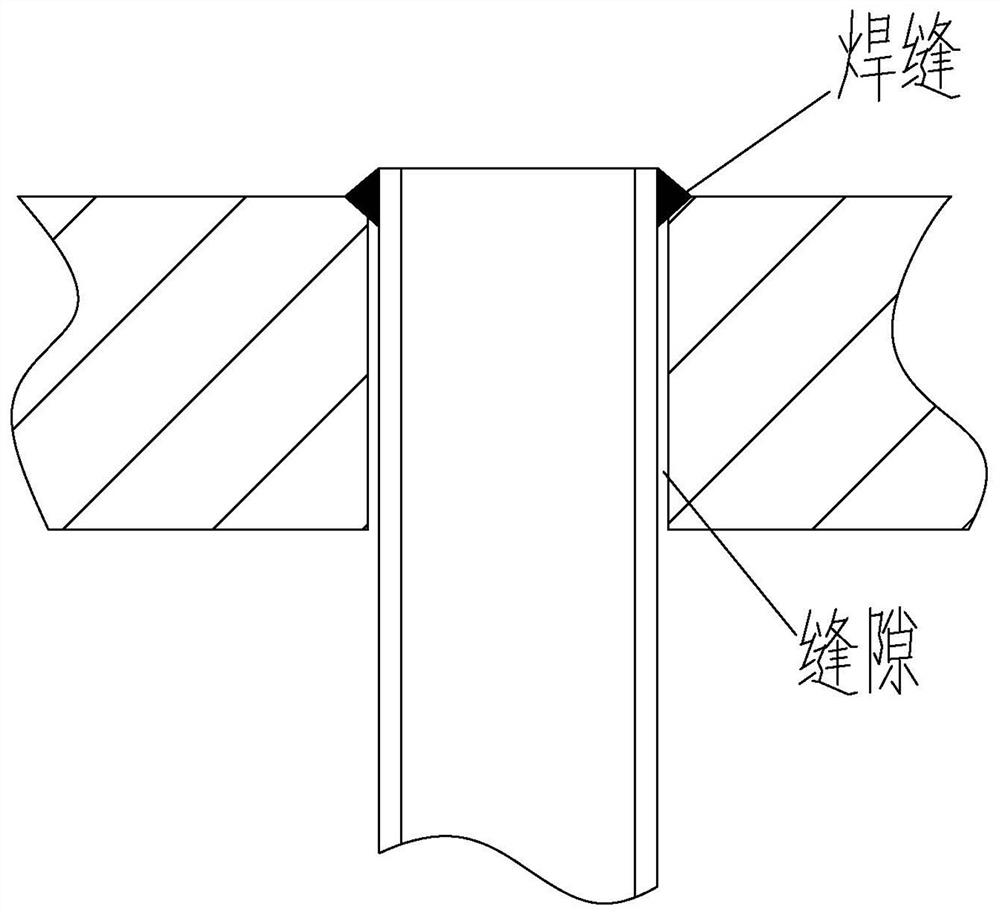

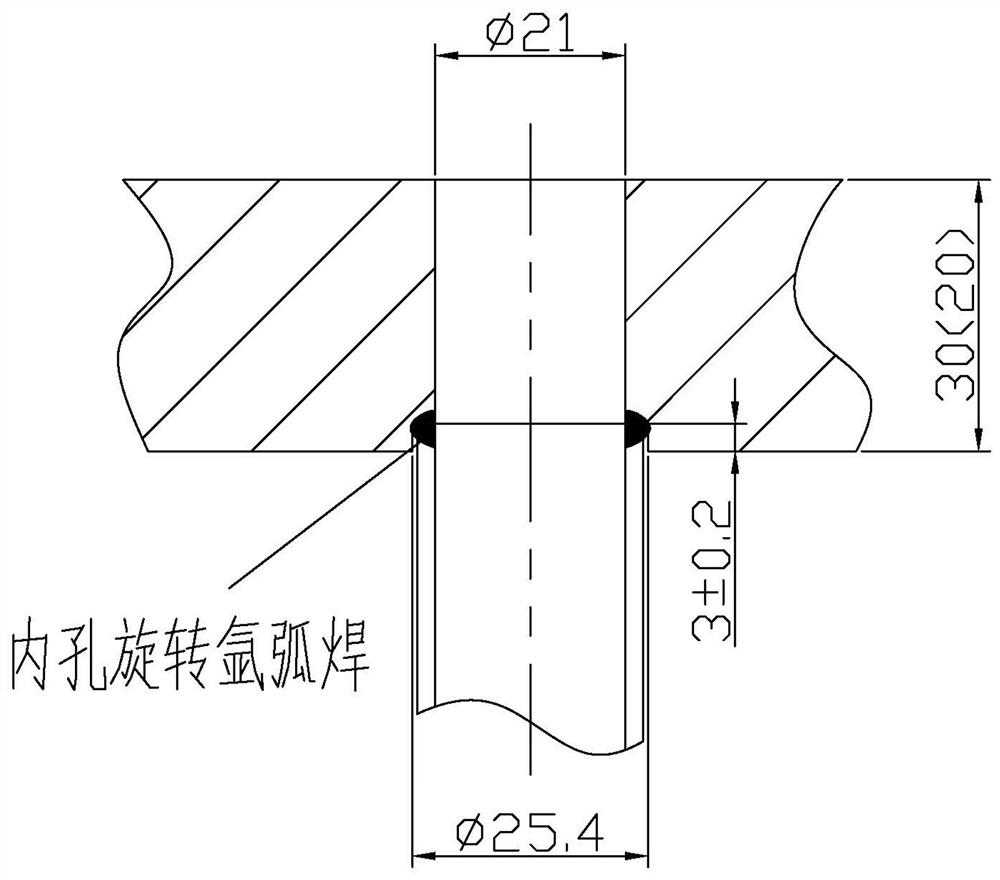

Inner hole rotary argon arc welding gun head of pipe and pipe plate and welding method

A technology of argon arc welding and tube, which is applied in the welding field of heat exchanger pipe fittings and tube sheets, which can solve the problems of small inner holes, inconvenient wire addition, and difficulty in the tube and sheet seams at the tube head, so as to reduce heat accumulation and form weld seams Uniform, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

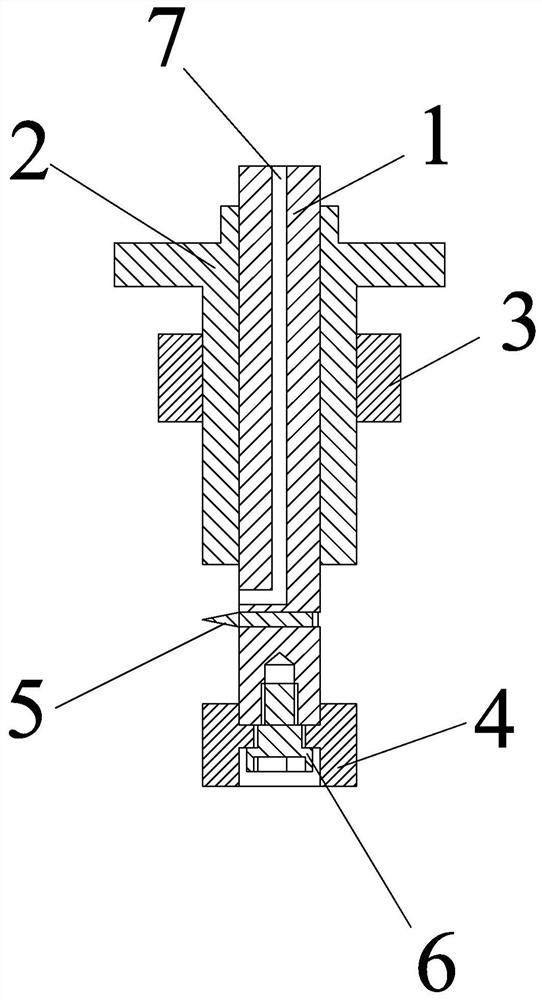

[0028] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0029] A kind of inner hole rotary argon arc welding torch head of a tube and a tube sheet, such as image 3 and Figure 4 As shown: it includes a conductive mandrel 1, the upper part of the conductive mandrel 1 is sleeved with an upper positioning insulating sleeve 2, and the upper part of the upper positioning insulating sleeve 2 is also integrally connected with a ring plate, and the outer part of the upper positioning insulating sleeve 2 An adjustable nut 3 is threadedly connected, and a shielding gas hole 7 is provided inside the conductive mandrel 1. The inlet of the shielding gas hole 7 is arranged along the axial direction of the conductive mandrel 1, and the outlet is located at the lower part of the conductive mandrel 1 and along the radial direction. Extending to the outside of the conductive mandrel 1; the lower body of the conductive mandr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com