Manufacturing method of heat dissipation silicone grease

A production method and technology of silicone grease, which is applied in the field of silicone grease processing, can solve problems such as difficult temperature control, reduced processing efficiency, and time-consuming, and achieve the effects of improving cleaning effect, improving processing efficiency, and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

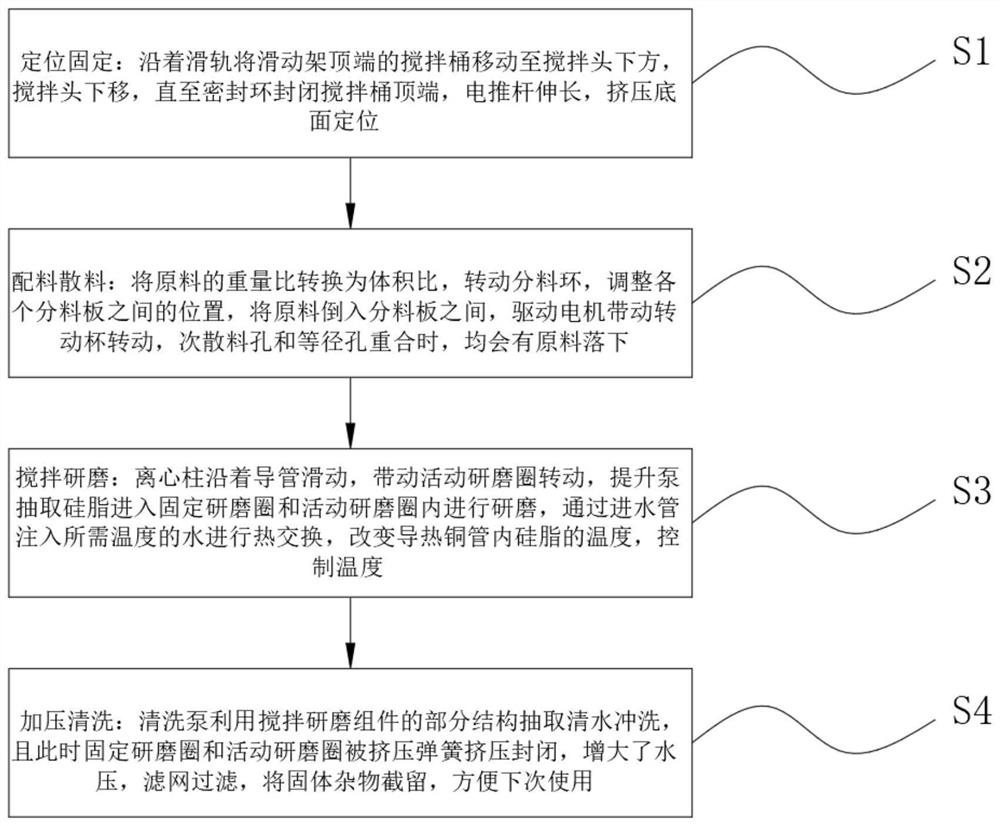

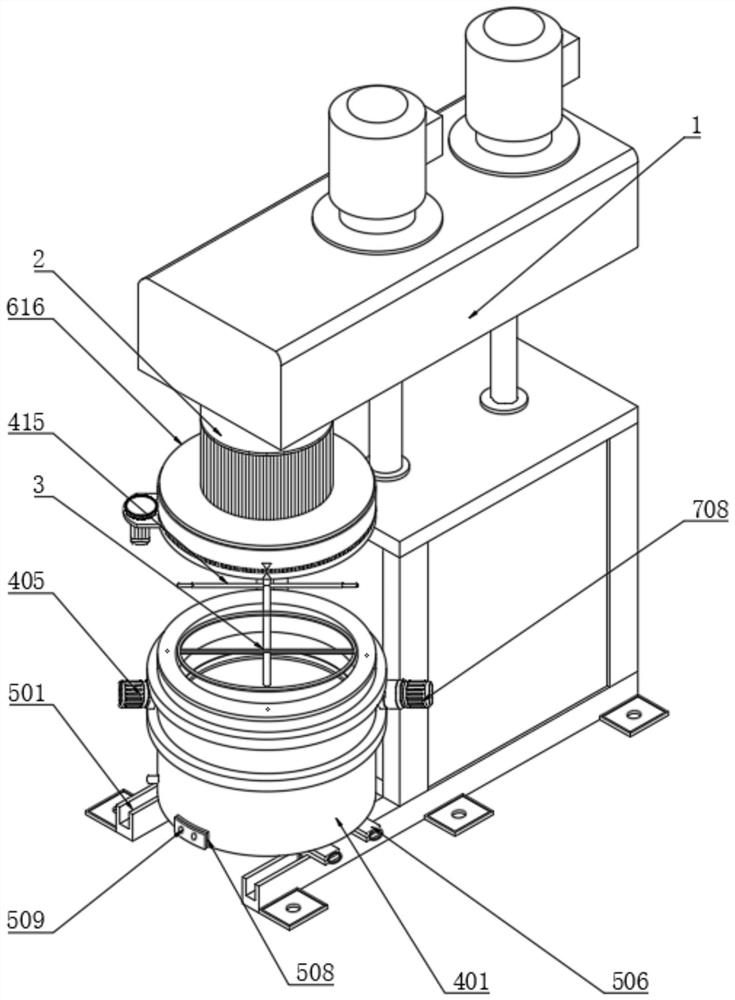

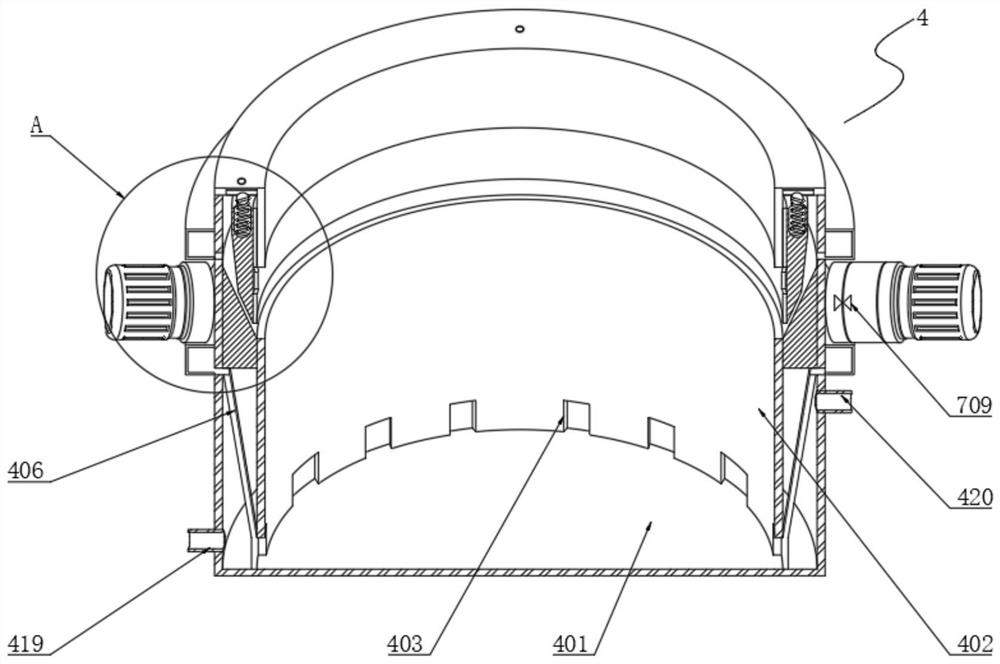

[0046] Example: such as Figure 1-9 As shown, the present invention provides a technical solution for a method for producing heat-dissipating silicone grease, which is characterized in that it includes the following steps:

[0047] S1. Fixed positioning: move the mixing bucket 401 at the top of the sliding frame 502 to the bottom of the mixing head 2 along the slide rail 501, and the mixing head 2 moves down until the sealing ring 601 closes the top of the mixing bucket 401, and the electric push rod 504 is extended and squeezed. Positioning of the bottom surface;

[0048] S2. Batching bulk materials: convert the weight ratio of raw materials into volume ratio, rotate the material distribution ring 611, adjust the position between the distribution plates 612, pour the raw materials into the space between the material distribution plates 612, and drive the motor 606 to drive the rotating cup 602 rotates, and when secondary bulk material hole 603 and equal-diameter hole 610 coi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap