Anti-crack recycled concrete as well as preparation method and application thereof

A technology of recycled concrete and recycled fine aggregate, applied in the field of concrete, can solve the problems of easy cracking, affect the normal use function and durability, etc., to improve the poor crack resistance, enhance the toughness and strength, and enhance the crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

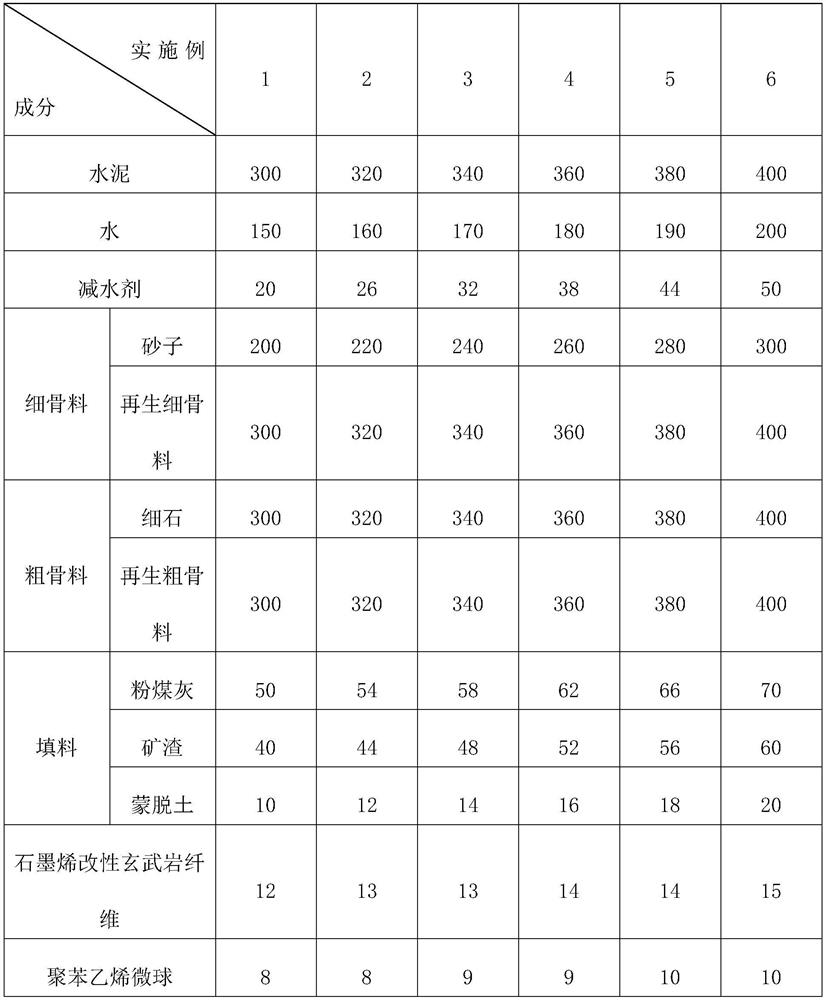

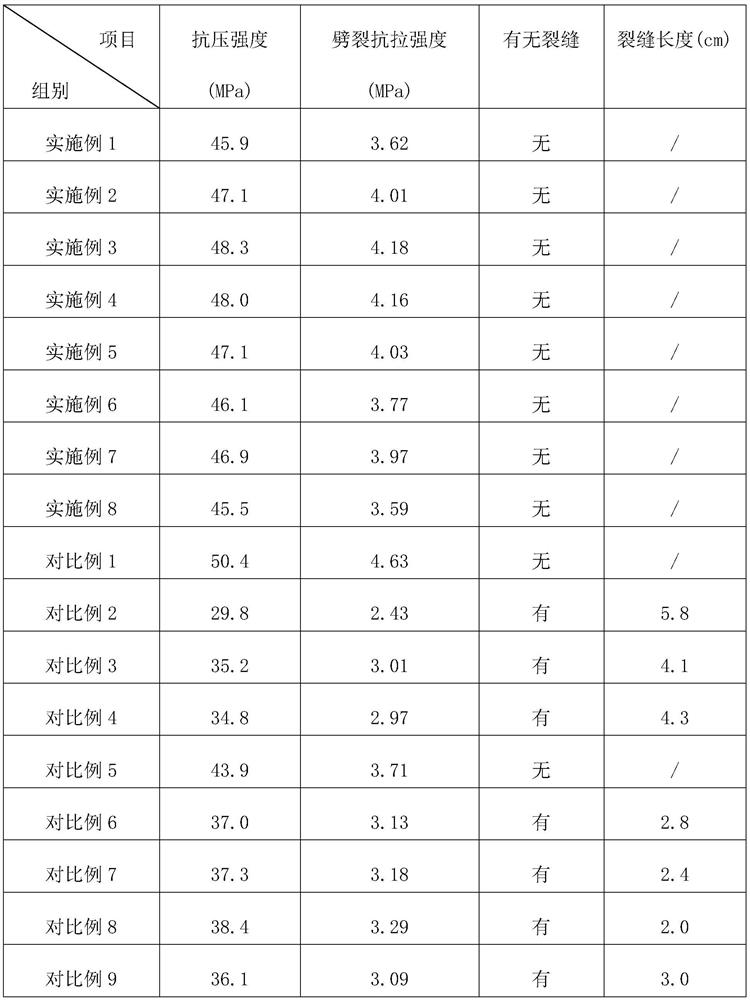

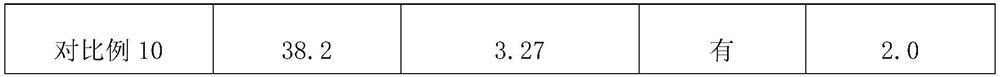

Method used

Image

Examples

preparation example 1

[0072] A graphene-modified basalt fiber, the preparation steps of which are: mixing basalt fiber, graphene, liquid paraffin, and silane coupling agent KH560 in a weight ratio of 1:0.02:0.05:0.05, and extruding with a twin-screw extruder For granulation, the temperature of the 5 stages of the twin-screw extruder from the feeding port to the machine head is set to 170°C, 185°C, 190°C, 190°C, 200°C in sequence, the screw speed is 200rpm, and the feeding speed is constant at 40rpm. After cooling, drying and pelletizing, graphene-modified basalt fibers are obtained. The diameter of the obtained graphene-modified basalt fibers is 8-12 μm and the length is 5-10 mm.

preparation example 2

[0074] A graphene-modified basalt fiber, the preparation steps of which are: mixing basalt fiber, graphene, liquid paraffin, and silane coupling agent KH560 in a weight ratio of 1:0.03:0.06:0.13, and extruding with a twin-screw extruder For granulation, the temperature of the 5 stages of the twin-screw extruder from the feeding port to the machine head is set to 170°C, 185°C, 190°C, 190°C, 200°C in sequence, the screw speed is 200rpm, and the feeding speed is constant at 40rpm. After cooling, drying and pelletizing, graphene-modified basalt fibers are obtained. The diameter of the obtained graphene-modified basalt fibers is 8-12 μm and the length is 5-10 mm.

preparation example 3

[0076] A graphene-modified basalt fiber, the preparation steps of which are: mixing basalt fiber, graphene, liquid paraffin, and silane coupling agent KH560 in a weight ratio of 1:0.05:0.08:0.2, and extruding with a twin-screw extruder For granulation, the temperature of the 5 stages of the twin-screw extruder from the feeding port to the machine head is set to 170°C, 185°C, 190°C, 190°C, 200°C in sequence, the screw speed is 200rpm, and the feeding speed is constant at 40rpm. After cooling, drying and pelletizing, graphene-modified basalt fibers are obtained. The diameter of the obtained graphene-modified basalt fibers is 8-12 μm and the length is 5-10 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com