Method for reducing size of B-type inclusions in aluminum deoxidized steel

An inclusion and aluminum deoxidation technology, applied in the field of iron and steel metallurgy and steelmaking, can solve the problems of little research on inclusion control, hydrogen-induced cracks in pipeline steel pipes, which have not been completely resolved, so as to avoid length, reduce rating level, reduce The effect of shapeshifting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

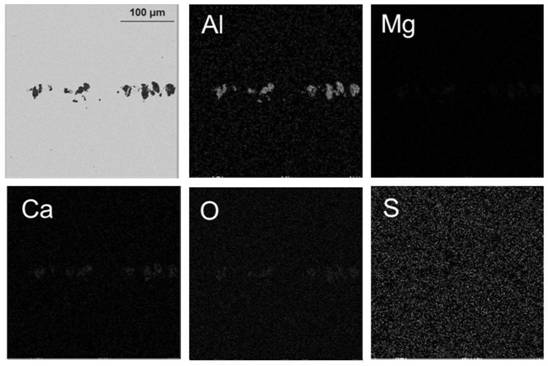

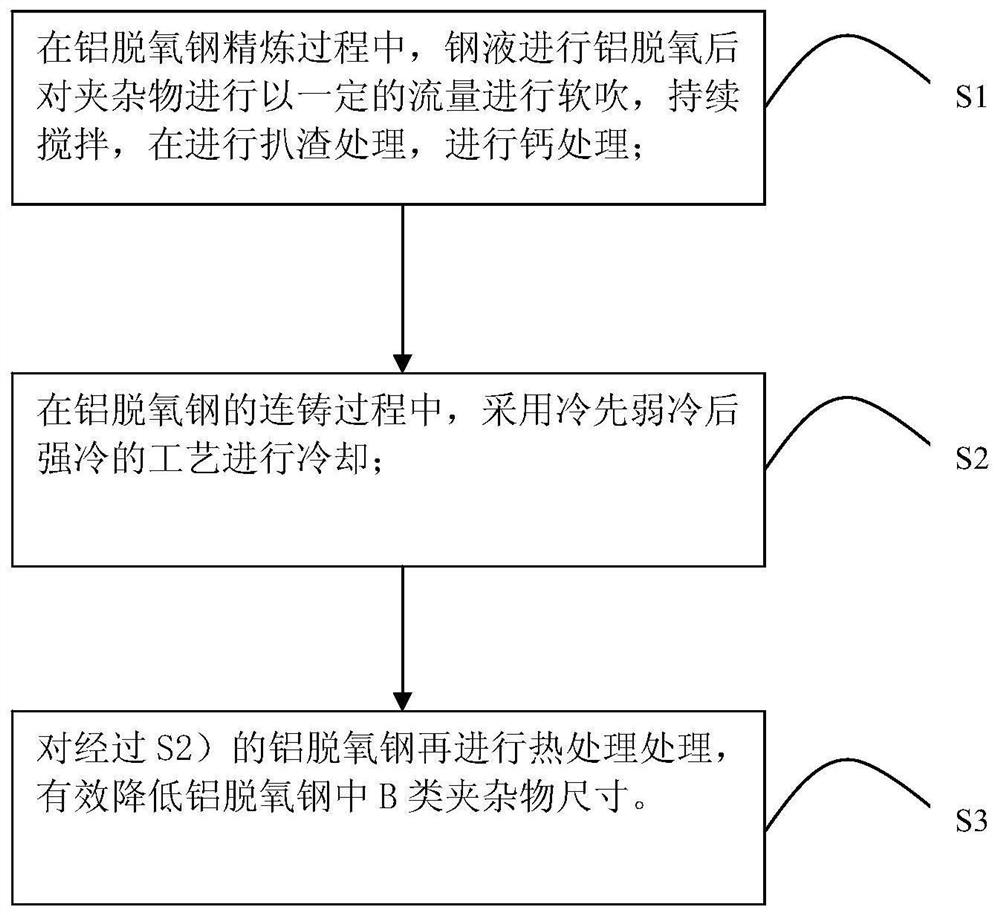

[0039] In the refining process of aluminum deoxidized steel, the molten steel is deoxidized by aluminum, and the inclusions are softly blown and stirred. The soft blowing time is 20 minutes, and the flow rate of argon blowing is 150NL / min, which promotes the floating and removal of large-sized alumina inclusions, and promotes Modification of inclusions; after slag removal, the thickness of slag in the ladle is 2.5 cm, and pre-melted refining slag with low melting point and high calcium-aluminum ratio is used. The main component of refining slag is 55% CaO-30% Al 2 o 3 -10% SiO2 2 -5% MgO, reduce the viscosity of refining slag, promote the adsorption and removal of inclusions and modify non-metallic inclusions; through feeding pure calcium wire calcium treatment, control the T.Ca content in the steel to 0.0011%, and the T.S content to 0.0015%. , to control inclusions in molten steel as CaO-Al 2 o 3 -MgO; In the continuous casting process of aluminum deoxidized steel, through...

Embodiment 2

[0041] In the refining process of aluminum deoxidized steel, the molten steel is subjected to aluminum deoxidation and soft blowing and stirring are carried out on the inclusions. The soft blowing time is 15 minutes, and the flow rate of argon blowing is 100NL / min, which promotes the floating and removal of large-sized alumina inclusions, and promotes the subsequent process. Modification of inclusions; after slag removal, the thickness of slag in the ladle is 2.5 cm, and pre-melted refining slag with low melting point and high calcium-aluminum ratio is used. The main component of refining slag is 55% CaO-30% Al 2 o 3 -10% SiO2 2 -5% MgO, reduce the viscosity of refining slag, promote the adsorption and removal of inclusions and modify non-metallic inclusions; through feeding pure calcium wire calcium treatment, control the T.Ca content in the steel to 0.0011%, and the T.S content to 0.0015%. , to control inclusions in molten steel as CaO-Al 2 o 3 -MgO; in the continuous cas...

Embodiment 3

[0043] In the refining process of aluminum deoxidized steel, the molten steel is deoxidized by aluminum, and the inclusions are softly blown and stirred. The soft blowing time is 18 minutes, and the flow rate of argon blowing is 200NL / min, which promotes the floating and removal of large-sized alumina inclusions, and promotes Modification of inclusions; after slag removal, the thickness of slag in the ladle is 2.5 cm, and pre-melted refining slag with low melting point and high calcium-aluminum ratio is used. The main component of refining slag is 55% CaO-30% Al 2 o 3 -10% SiO2 2 -5% MgO, reduce the viscosity of refining slag, promote the adsorption and removal of inclusions and modify non-metallic inclusions; through feeding pure calcium wire calcium treatment, control the T.Ca content in the steel to 0.0011%, and the T.S content to 0.0015%. , to control inclusions in molten steel as CaO-Al 2 o 3 -MgO; in the continuous casting process of aluminum deoxidized steel, through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com