Three-dimensional composite negative electrode material for sodium-ion battery and preparation method and application of three-dimensional composite negative electrode material

A sodium-ion battery, three-dimensional composite technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve problems such as low output and complicated preparation process, and achieve high discharge capacity and high reversible ratio Capacity, the effect of promoting rapid transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

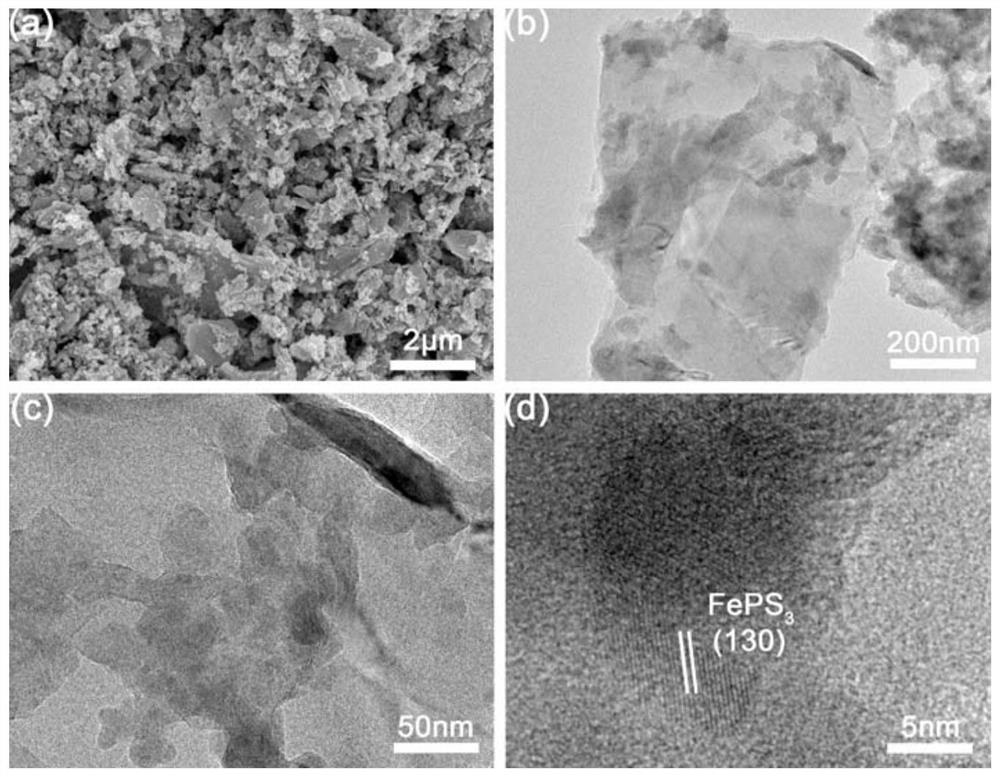

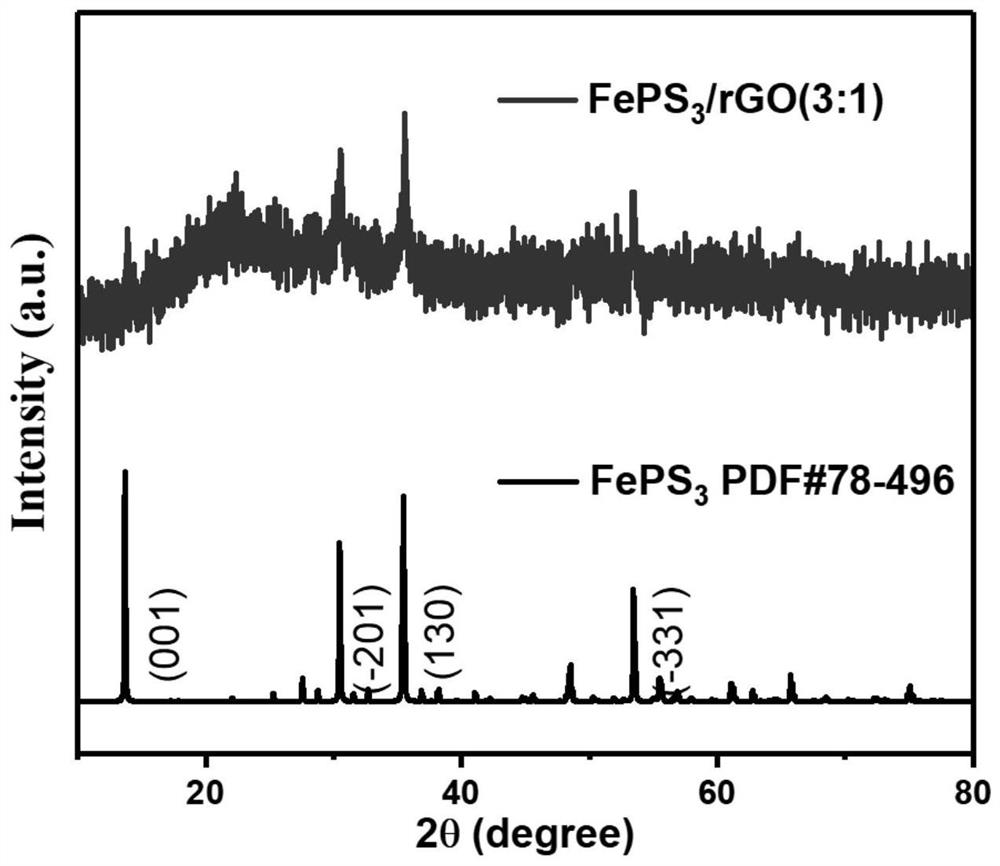

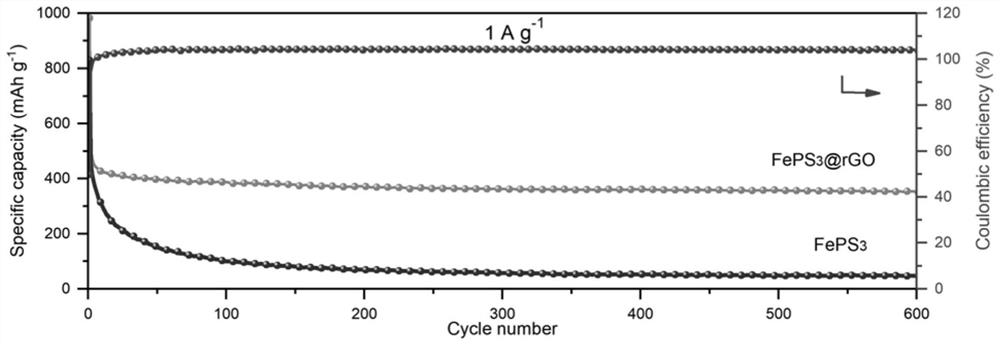

[0049] The three-dimensional composite negative electrode material of the sodium ion battery of the present embodiment has a lamellar structure, including reduced graphene oxide sheets and FePS attached to the reduced graphene oxide sheets 3 .

[0050] The preparation method of the three-dimensional composite negative electrode material of the sodium ion battery of the present embodiment comprises the following steps:

[0051] (1) Mix iron powder, red phosphorus powder and sublimed sulfur according to the molar ratio of 1:1:3, grind them thoroughly, and then seal them in a quartz ampoule under vacuum conditions (vacuum degree is 10 -6 mbar), heated to 750 °C at a heating rate of 1 °C / min in a muffle furnace and sintered for 6 days to obtain bulk FePS 3 crystal;

[0052] (2) The prepared bulk FePS 3 The crystal is placed in a quartz tube, and in an argon atmosphere, the temperature is raised to 500 °C at a rate of 2 °C / min and calcined for 2 h for annealing treatment to obta...

Embodiment 2

[0058] The three-dimensional composite negative electrode material of the sodium ion battery of the present embodiment has a lamellar structure, including reduced graphene oxide sheets and FePS attached to the reduced graphene oxide sheets 3 .

[0059] The preparation method of the three-dimensional composite negative electrode material of the sodium ion battery of the present embodiment comprises the following steps:

[0060] (1) Mix iron powder, red phosphorus powder and sublimed sulfur according to the molar ratio of 1:1:3, grind them thoroughly, and then seal them in a quartz ampoule under vacuum conditions (vacuum degree is 10 -6 mbar), heated to 750 °C at a heating rate of 1 °C / min in a muffle furnace and sintered for 6 days to obtain bulk FePS 3 crystal;

[0061] (2) The prepared bulk FePS 3 The crystal is placed in a quartz tube, and in an argon atmosphere, the temperature is raised to 500 °C at a rate of 2 °C / min and calcined for 2 h for annealing treatment to obta...

Embodiment 3

[0067] The three-dimensional composite negative electrode material of the sodium ion battery of the present embodiment has a lamellar structure, including reduced graphene oxide sheets and FePS attached to the reduced graphene oxide sheets3 .

[0068] The preparation method of the three-dimensional composite negative electrode material of the sodium ion battery of the present embodiment comprises the following steps:

[0069] (1) Mix iron powder, red phosphorus powder and sublimed sulfur according to the molar ratio of 1:1:3, grind them thoroughly, and then seal them in a quartz ampoule under vacuum conditions (vacuum degree is 10 -6 mbar), heated to 750 °C at a heating rate of 1 °C / min in a muffle furnace and sintered for 6 days to obtain bulk FePS 3 crystal;

[0070] (2) The prepared bulk FePS 3 The crystal is placed in a quartz tube, and in an argon atmosphere, the temperature is raised to 500 °C at a rate of 2 °C / min and calcined for 2 h for annealing treatment to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radial width | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com