Inter-assembly joint structure of photovoltaic string and photovoltaic string structure

A photovoltaic module and photovoltaic group technology, applied in the field of solar energy, can solve the problems of large power generation performance loss of the system, and achieve the effect of reliable connection and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

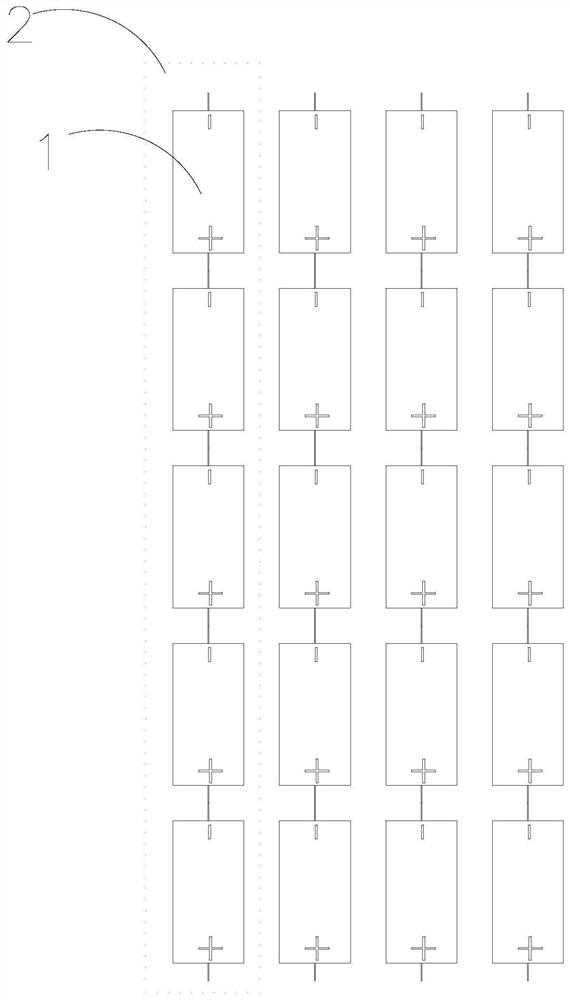

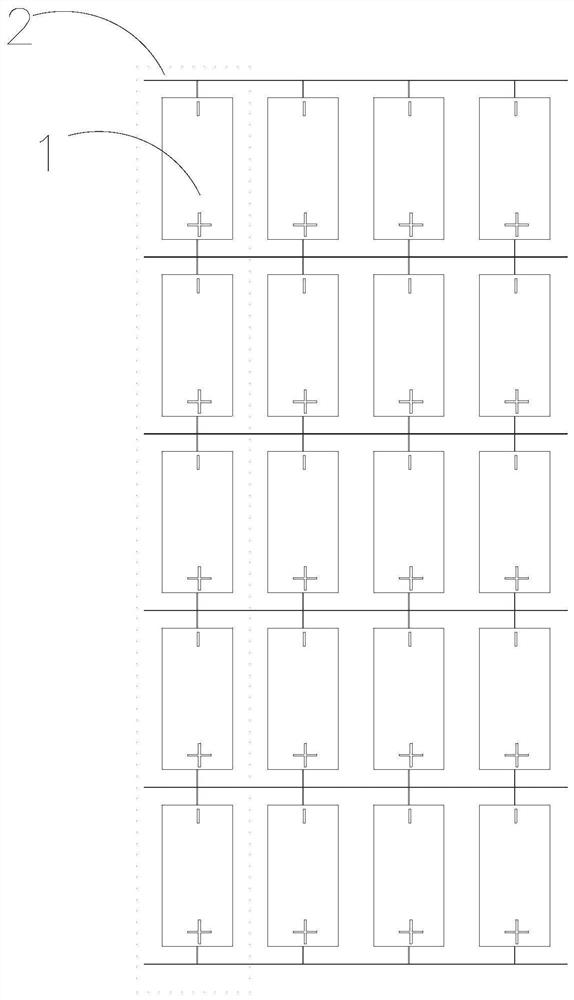

[0037] see image 3 As shown, the present invention provides a photovoltaic string structure, including several photovoltaic modules 1; several photovoltaic modules 1 are connected in series to form a photovoltaic string 2.

[0038] A photovoltaic string with a series-parallel structure in the present invention includes at least two photovoltaic strings 2 .

[0039] The photovoltaic modules 1 in a photovoltaic string 2 are connected in parallel with the corresponding photovoltaic modules 1 in the adjacent photovoltaic string 2 to form a photovoltaic string structure in which all photovoltaic modules are connected in series and in parallel.

[0040] In the present invention, the photovoltaic module 1 can use any solar cell, for example: GaAs single-junction solar cell, single-junction dye-sensitized solar cell, single-junction silicon thin film solar cell, crystalline silicon solar cell, cadmium telluride solar cell and copper indium gallium Selenium solar cells, etc.

[0041...

Embodiment 2

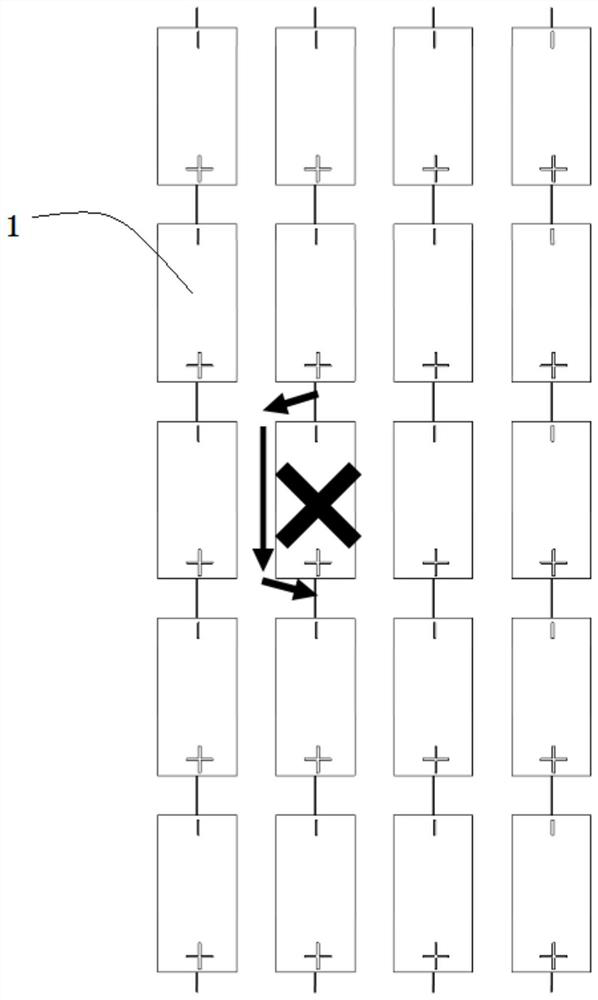

[0043] The photovoltaic modules 1 are connected to each other by direct welding with wires or conventional quick plug connection; however, when a photovoltaic string structure of the present invention is adopted, the adjacent photovoltaic modules 1 of the adjacent photovoltaic strings 2 need to be connected in parallel, if If the wire welding method is used, the welding between the wires will be involved, the process is not easy to realize, and the reliability is not high.

[0044] The direct insertion of the conventional quick plug MC4 male head and the MC4 female head realizes the connection conduction, but it is also used to realize the communication between the two wires. A photovoltaic string structure of the present invention requires photovoltaic modules 1 to be connected both in series and in parallel, which involves the connection between four wires, and there is no reliable solution in the prior art.

[0045] In order to solve these technical problems, the present in...

Embodiment 3

[0053] Embodiment 3 differs from Embodiment 2 in that the first parallel connection port 303 and the second parallel connection port 304 are replaced by MC4 connectors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com