Lime shell processing equipment

A processing equipment and lime fruit technology, applied in the field of lime husk processing equipment, can solve the problems of low processing efficiency of manual operation, consuming a lot of time and energy, and unable to obtain market income, etc., achieving ingenious structural design and liberating manpower. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

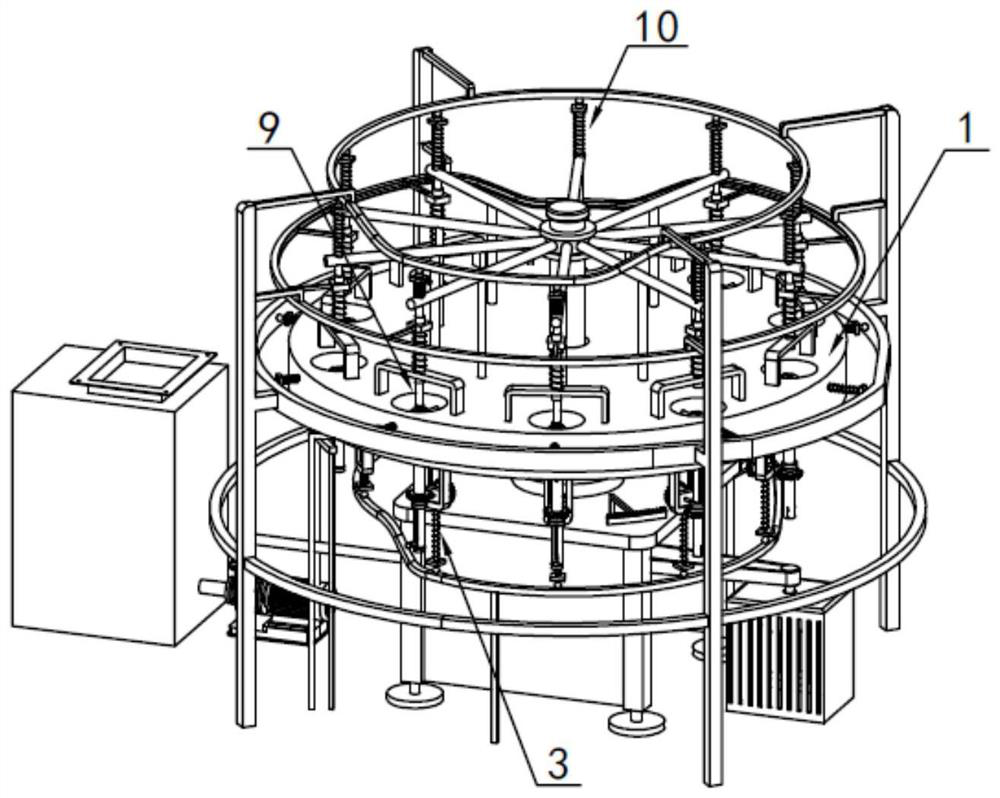

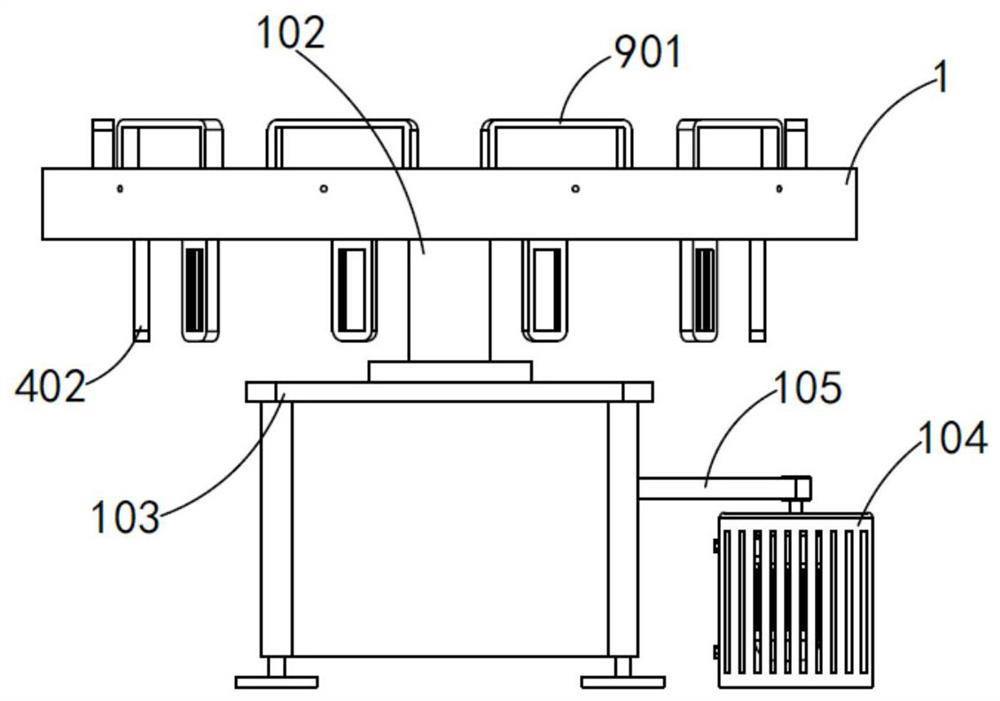

[0044] Such as Figure 1 to Figure 16 As shown, a lime husk processing equipment includes a processing turntable 1, and the processing turntable 1 is provided with a plurality of supporting grooves 101 distributed in a circumferential array, and the supporting grooves 101 are used to limit and support a single lime. A clamping assembly 2 is provided in the support groove 101, and the clamping assembly 2 is used to fix and clamp a single lime in the support groove 101 during the rotation process. The separation mechanism 3 at the bottom of the processing turntable 1, the separation mechanism 3 includes a cover removal assembly 4, a flip assembly 5, a scraper assembly 6, a push assembly 7 and an autorotation assembly 8, and the cover removal assembly 4 includes a cover removal ring 401, the The lid removal assembly 4 removes the lid from the clamped lime by vertically upward lifting, and pulls the lid out under the action of the lid removal ring 401 in the form of an upside-down...

Embodiment 2

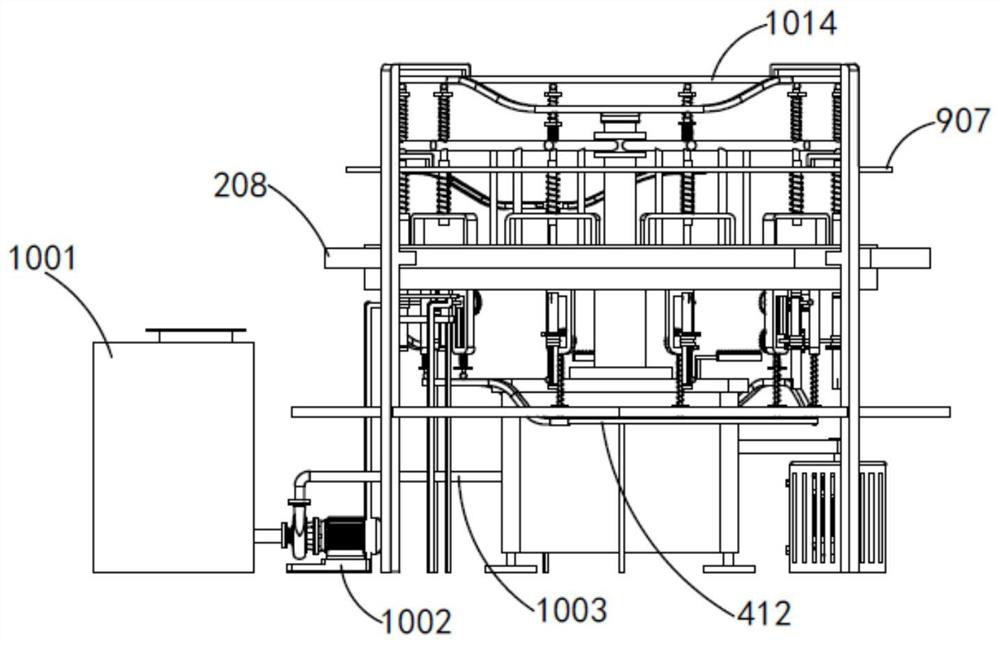

[0056] Such as Figure 17 to Figure 20 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that a sliding flushing assembly 10 is also provided in the pressing assembly 9, and the flushing assembly 10 includes a water tank 1001, a water pump 1002 connected with the water tank 1001 and a main water pipe 1003 connected with the water pump 1002, the main water pipe 1003 is set in the hollow rotating shaft 102, the upper end of the main water pipe 1003 is provided with a pair of fixed limit support blocks 1004, and several drainage pipes 1005 are arranged on the limit support block 1004, and the main water pipe 1003 is A number of water channels 1006 are arranged between the position-limiting support blocks 1004. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com