A continuous flow reaction device and a method for the flow synthesis of bis(fluorosulfonyl)imide based on the device

A reaction device, fluorosulfonyl technology, applied in the direction of separation methods, feeding devices, chemical instruments and methods, etc., can solve the problems of difficult separation of by-products, high safety risks, high energy consumption, etc., to shorten the reaction time and reduce by-products Response, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

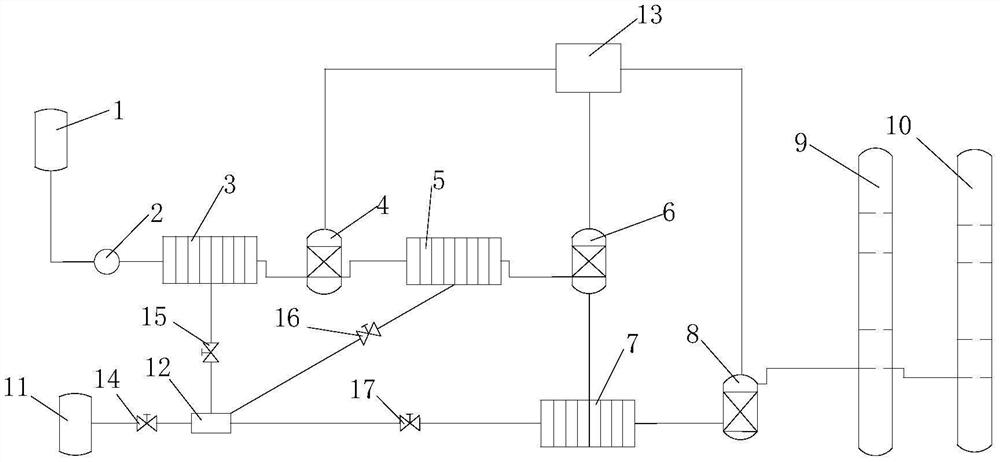

[0030] like figure 1 As shown, the continuous flow reaction device of the present invention comprises a jacket heat exchanger 1, a metering pump 2, a first microchannel reactor 3, a first gas-liquid separation system 4, a second microchannel reactor 5, The second gas-liquid separation system 6, the third micro-channel reactor 7, the third gas-liquid separation system 8, the delight tower 9 and the rectification tower 10, also include a liquid booster system 11, a mass flow meter 12 and a tail gas absorption system 13. The liquid pressurization system 11 is respectively communicated with the first microchannel reactor 3, the second microchannel reactor 5 and the third microchannel reactor 7 through the mass flow meter 12, and the liquid pressurization system 11 is connected to the mass A first shut-off valve 14 is provided between the flow meters 12, and a second micro-channel reactor 12 is provided between the mass flow meter 12 and the first micro-channel reactor 3, the secon...

Embodiment 2

[0035] Use the continuous flow reaction device of Example 1 to prepare high-purity HFSI by continuous flow, and the specific steps are as follows:

[0036] The reaction temperature of the first microchannel reactor 3, the second microchannel reactor 5 and the third microchannel reactor 7 was set to 90°C. HClSI and N,N-dimethylformamide (DMF) were mixed to form a material 1, which was charged into a jacketed heat exchanger 1 and preheated to 60°C. The amount of DMF added was 3.3% of the mass of HClSI. Anhydrous AHF is pressurized to 1.2MPa by the liquid pressurizing system 11 for standby.

[0037] The preheated material 1 in the jacket heat exchanger 1 was pumped into the first microchannel reactor 3 through the metering pump 2, and the flow rate was 24ml / min, and was heated to 90 through the preheating module of the first microchannel reactor 3. After ℃, it enters the reaction module group. When the material 1 is filled with the reaction module group, the first shut-off valve...

Embodiment 3

[0039] Use the continuous flow reaction device of Example 1 to prepare high-purity HFSI by continuous flow, and the specific steps are as follows:

[0040] The reaction temperature of the first microchannel reactor 3, the second microchannel reactor 5 and the third microchannel reactor 7 was set to 120°C. HClSI and dibutyl butyl phosphonate (DBBP) were mixed to form a material 1, which was charged into a jacketed heat exchanger 1 and preheated to 60° C., and the amount of DBBP added was 5.7% of the mass of HClSI. Anhydrous AHF is pressurized to 1.2MPa by the liquid pressurizing system 11 for standby.

[0041] The preheated material 1 in the jacket heat exchanger 1 was pumped into the first microchannel reactor 3 through the metering pump 2, and the flow rate was 24ml / min, and was heated to 120 through the preheating module of the first microchannel reactor 3. After ℃, it enters the reaction module group. When the material 1 is filled with the reaction module group, the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com