Precise front axle crankshaft composite full-automatic hot die forging production line

A fully automated and compound technology, applied in engine components, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve problems such as large differences in shape, low degree of automation, and poor anti-eccentric load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

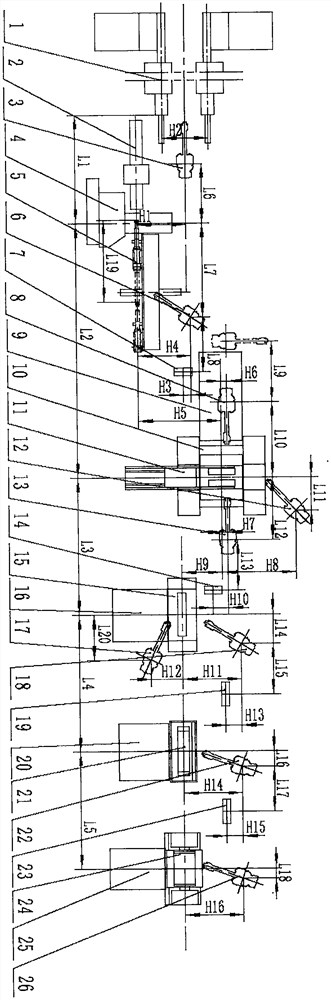

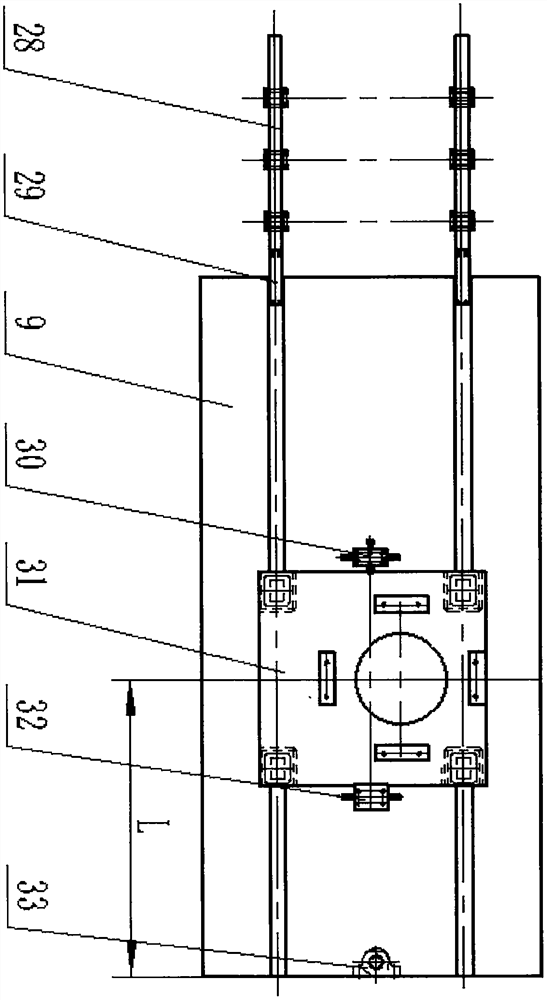

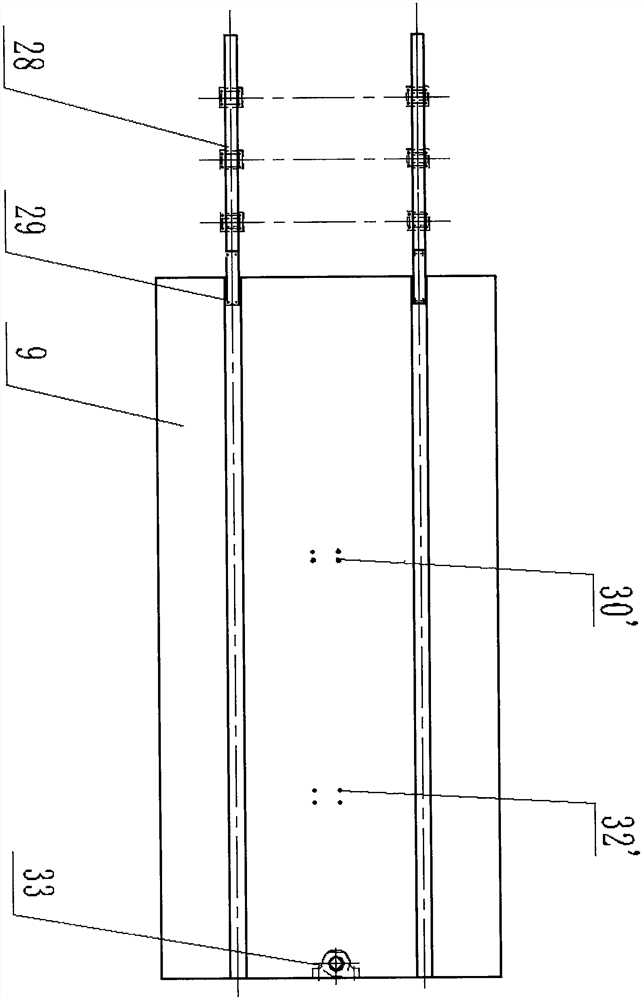

[0012] In this example figure 1 It is the general layout plan of the precision front axle crankshaft composite fully automatic hot die forging production line. The whole line includes 8 sets of forging equipment, namely intermediate frequency furnace (1), descaling device (2), roll forging machine (4), roll forging machine operator (5), 10,000-ton hot die forging press (10), trimming press (15), twisting press (21), correction press (24); 9 robots are R1 robot (3), R2 operation Robot (6), R3 operation robot (8), R4 spray lubrication robot (12), R5 operation robot (13), R6 flash removal robot (17), R6 flash removal robot (17), R7 operation robot (18 ), R8 operating robot (22), R9 operating robot (26); 4 sets of transfer table namely 1# transfer table (7), 2# transfer table (14), 3# transfer table (19) and 4 #Transfer material table (23); auxiliary device, auxiliary device includes withdrawal guide rail (28), mold change table (9), quick change device and bus control system, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com