Numerical control machine tool facilitating water drainage

A technology of CNC machine tools and machine bodies, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as reduced performance, blockage of coolant, and inability to cool in time, so as to facilitate cooling work, reduce blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

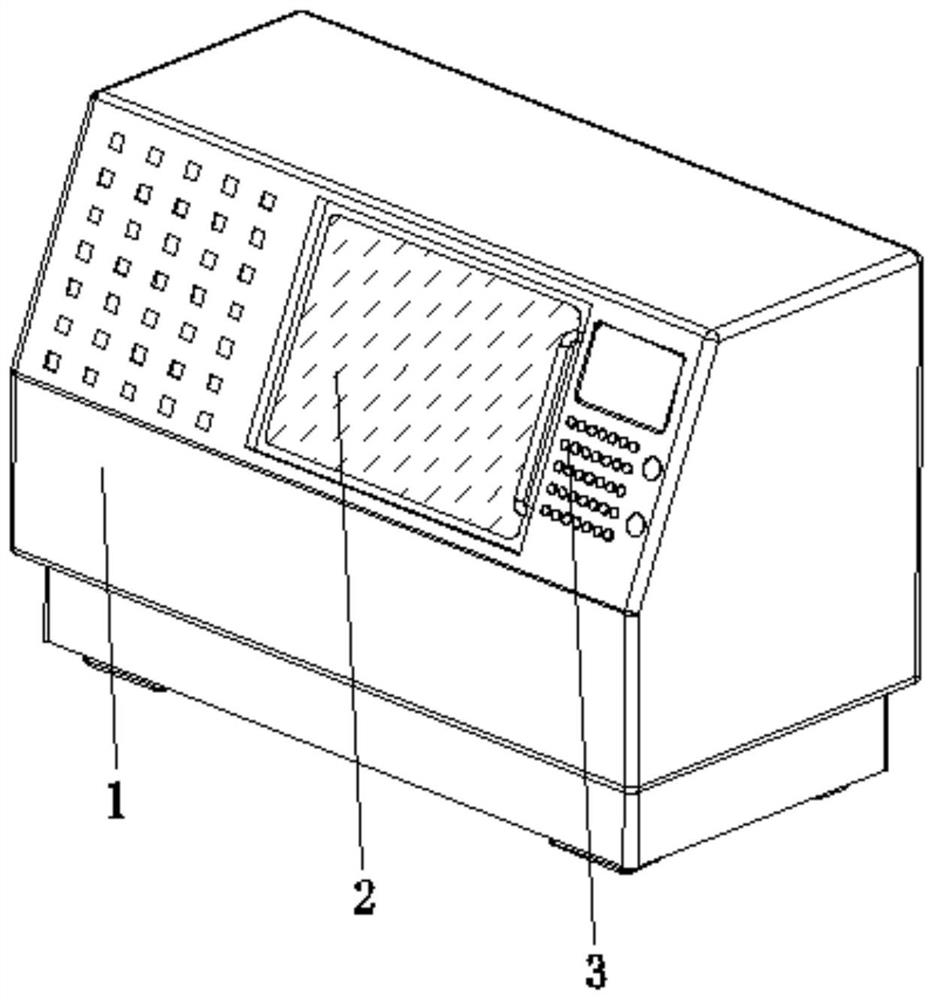

[0029] see Figure 1-6 , the present invention provides a technical solution: a convenient drainage type CNC machine tool, including a housing 1, a sliding door 2, and an operating surface 3, the sliding door 2 is arranged on one side of the surface of the housing 1 and is located in the center, and the operating surface 3 Set on the surface side of the housing 1 and close to the sliding door 2;

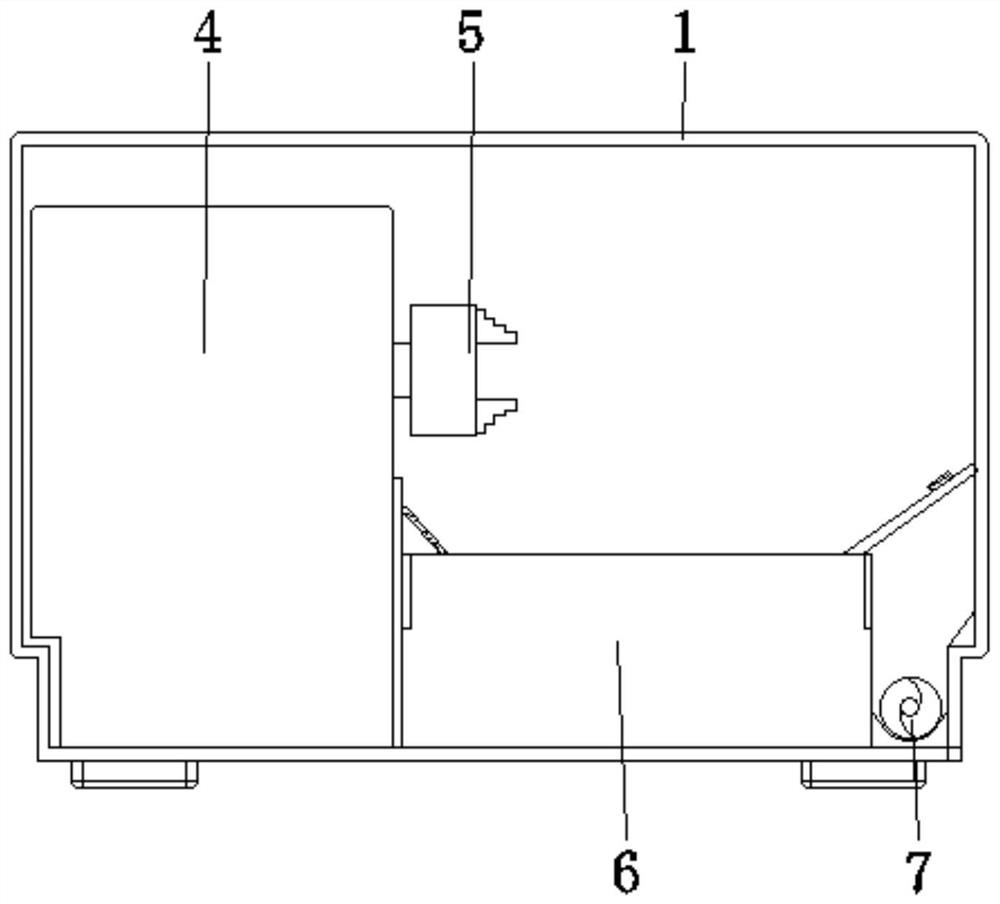

[0030] The inside of the housing 1 is provided with a body 4, a clamping drive mechanism 5, a water storage device 6, and a jiaolong chip removal mechanism 7. Extending to the outside, the water storage device 6 is arranged at the bottom of the inner wall of the housing 1 and is located at the position of the body 4, and the Jiaolong chip removal mechanism 7 is arranged at the bottom of the inner wall of the housing 1 and is located at the position of the water storage device 6, which can remove debris Turn it over in time to reduce the clogging caused by accumulation, which is cond...

Embodiment example 2

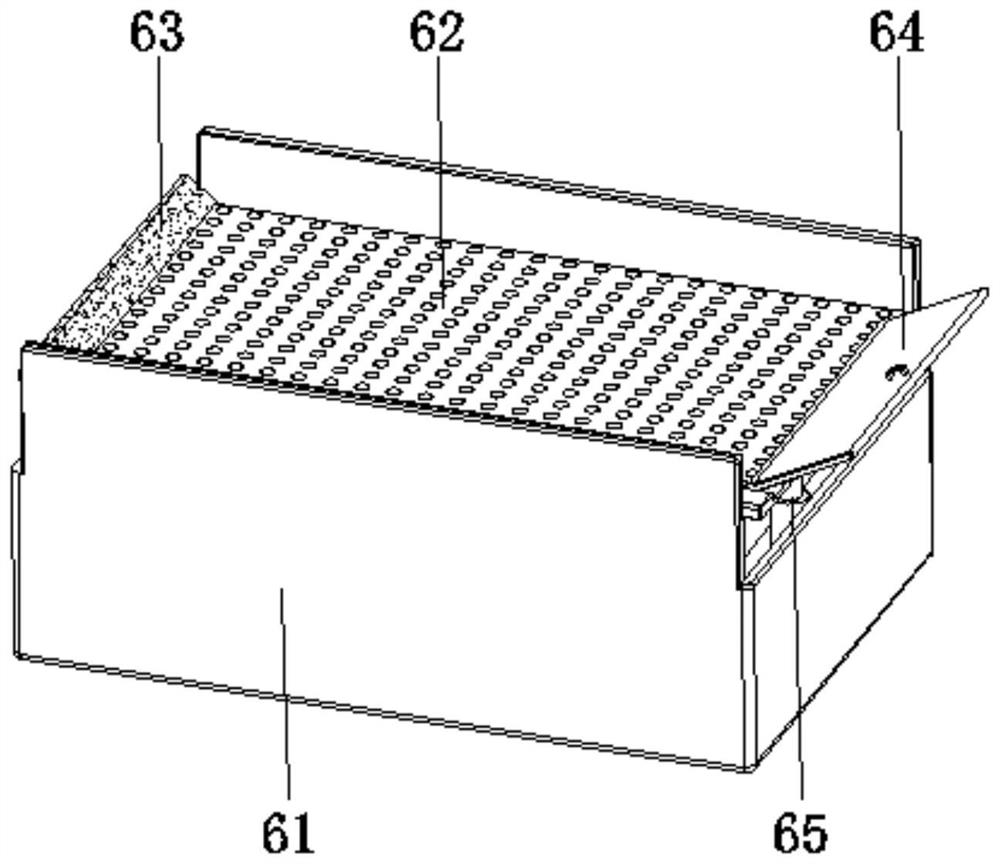

[0034] By setting the sieve plate 621, the baffle plate 622, the slide plate 623, the float 624, and the piercing device 625, when the cooling liquid smoothly flows down from the leakage hole on the sieve plate 621, the drainage is smooth, thereby reducing its own weight. Under the joint action of the buoyancy and the elastic telescopic device 65, the filter device 62 rises and circulates like this, so as to achieve the purpose of preventing clogging and make the drainage smooth.

Embodiment example 3

[0036]The piercing device 625 is provided with a support rod 6251, a conical top cap 6252, and a bar-shaped hole 6253. The bottom end of the support rod 6251 is fixedly connected to the top of the slide plate 623, and the top of the inner wall of the conical top cap 6252 is fixedly connected to the top of the support rod 6251. , the strip-shaped holes 6253 are opened on the surface of the conical top cap 6252, and the strip-shaped holes 6253 are evenly distributed on the surface of the conical top cap 6252. When it is lifted up, the coolant flows downward from the strip hole 6253 in time, and the accumulated debris is turned over to leak out of the leak hole on the sieve plate 621, allowing the coolant to flow out smoothly, thereby achieving the effect of facilitating drainage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com