Antibacterial mildew-proof thermochromic master batch and household article preparation method thereof

A temperature-sensitive discoloration, antibacterial and anti-mold technology, which is applied in the field of plastic coloring, can solve the problems of reduced smoothness, sticky product surface, and disease infection, and achieve the effect of increasing the interest of life and excellent anti-bacterial and anti-mold properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under normal temperature and pressure, send 10kg of temperature-sensitive pigment vermilion, 10kg of temperature-sensitive pigment brown, 0.8kg of ordinary pigment yellow, 0.2kg of dispersant, 0.2kg of succinic anhydride, 0.2kg of antibacterial agent, and 66.8kg of polyethylene resin into the mixer. The stirring speed is 100-120r / min, 30 minutes, stirring and mixing evenly into a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, the extrusion temperature is controlled at 150-170°C, extruded to form a strand, and then the strand is cooled by a water tank and then enters a pelletizer for granulation to obtain Antibacterial and anti-mildew thermochromic masterbatch.

Embodiment 2

[0024] Under normal temperature and pressure, send 10kg of temperature-sensitive pigment vermilion, 10kg of temperature-sensitive pigment brown, 0.8kg of ordinary pigment yellow, 0.2kg of dispersant, 0.2kg of succinic anhydride, 0.2kg of antibacterial agent, and 66.8kg of polyethylene resin into the mixer. The stirring speed is 100-120r / min, 30 minutes, stirring and mixing evenly into a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, the extrusion temperature is controlled at 150-170°C, extruded to form a strand, and then the strand is cooled by a water tank and then enters a pelletizer for granulation to obtain Antibacterial and anti-mildew thermochromic masterbatch.

[0025] Example 2:

[0026] Under normal temperature and pressure, send 15kg of temperature-sensitive pigment vermilion, 15kg of temperature-sensitive pigment brown, 1.2kg of ordinary pigment yellow, 0.4kg of dispersant, 0.4kg of succinic anhydride, 0.4kg of antibacterial agent...

Embodiment 3

[0028] Under normal temperature and pressure, send 12kg of temperature-sensitive pigment vermilion, 13kg of temperature-sensitive pigment coffee color, 1kg of ordinary pigment yellow, 0.3kg of dispersant, 0.3kg of succinic anhydride, 0.3kg of antibacterial agent, and 70kg of polyethylene resin into the mixer. 100~120r / min, 30 minutes, stir and mix evenly to form a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, the extrusion temperature is controlled at 150-170°C, extruded to form a strand, and then the strand is cooled by a water tank and then enters a pelletizer for granulation to obtain Antibacterial and anti-mildew thermochromic masterbatch.

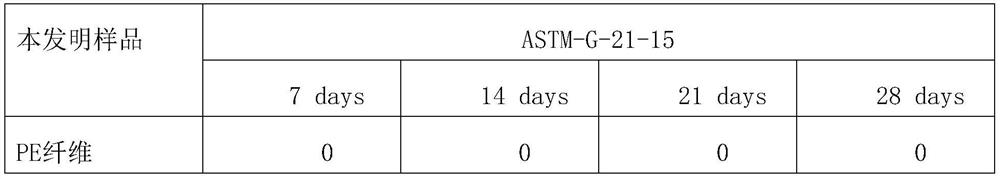

[0029] In the above examples, the antibacterial agent is formed by mixing isothiazolinone and silver ions. Silver ion antibacterial agents have the characteristics of high efficiency, broad spectrum, long duration, etc., and are non-toxic, odorless, and have no impact on the environment. When a sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com