Spray type anti-static finishing device and fabric anti-static finishing process

A finishing device and anti-static technology, which is applied in spraying/spraying textile material processing, equipment configuration for processing textile materials, fiber processing, etc., can solve the problem of insufficient anti-static effect of fabrics, uneven distribution of anti-static finishing agents, and anti-static effect Insufficient uniformity and other problems, to achieve better hand feeling, excellent antibacterial and antifungal properties, and appropriate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

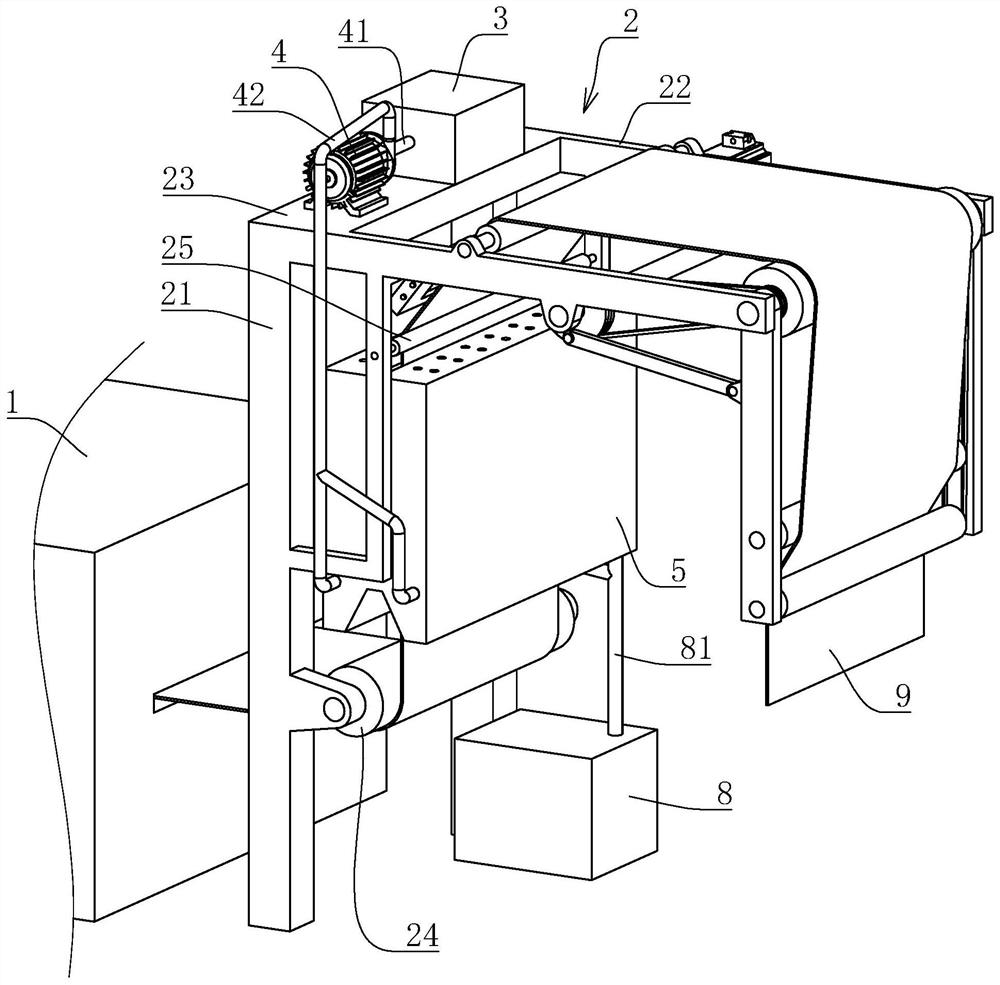

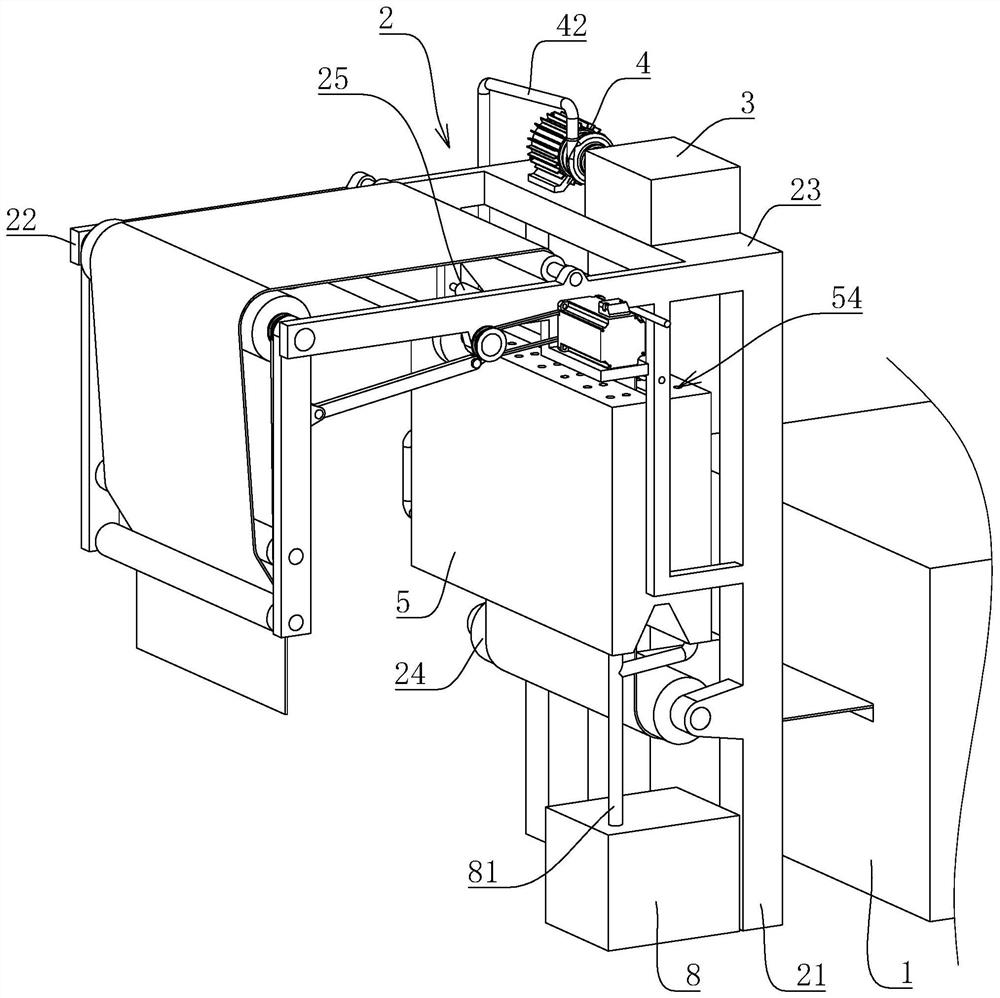

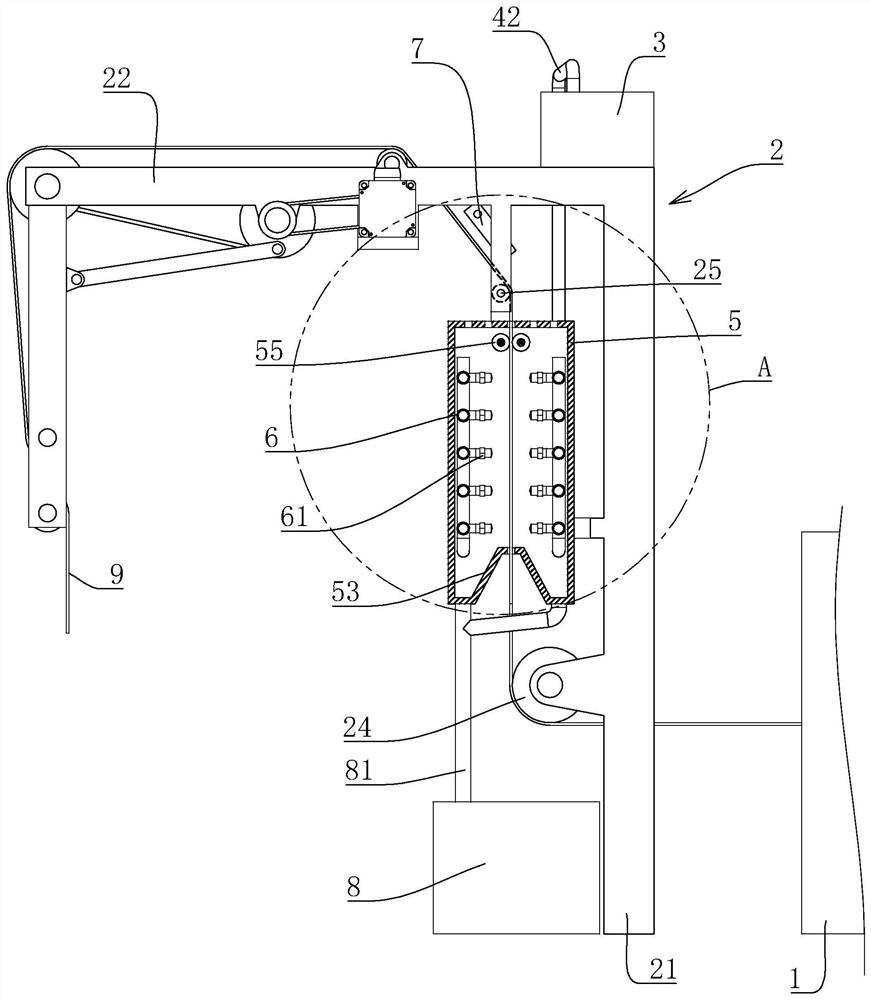

[0071] refer to figure 1 and figure 2 , is a spray type antistatic finishing device disclosed by the present invention, which includes a cloth drop frame 2 arranged at the cloth outlet end of the drying room 1 of the hot air stenter setting machine. The cloth drop frame 2 includes two vertical columns 21, a connecting beam 23 connected between the tops of the two vertical columns 21, and two horizontal beams 22. The beam 22 corresponds to the column 21 one by one, and one end is connected to the top of the column 21 . Guide rollers are arranged in the middle of the two beams 22 perpendicular to the length direction of the beams 22 , and a main friction roller parallel to the guide rollers is arranged at the end away from the column 21 . The surface of the main friction roller is covered with a rough rubber belt. The beam 22 is provided with a transmission shaft, and the end of the transmission shaft is connected with a private server motor. The drive shaft and the frictio...

Embodiment 2

[0095] A fabric anti-static finishing process, which is completed on the hot-air stenter setting and the spray-type anti-static finishing device of Example 1, refer to Figure 5 , including the following steps,

[0096] A heat setting: use a hot air stenter setting machine to perform heat setting treatment on the fabric 9, and the setting temperature is 180°C;

[0097] B Anti-static finishing liquid spray treatment:

[0098] P1. Configure the antistatic finishing solution according to the proportion, and temporarily store it in the liquid distribution tank 3; the formula of the antistatic finishing solution is as follows,

[0099] Polylactic acid porous microspheres 100 g

[0100] Chitin 100 g

[0101] Silk fibroin 140 g

[0102] Spirulina polysaccharide 25 g

[0103] Meteorological silica 20 g

[0104] Butanol 10 g

[0105] 750 g of deionized water;

[0106] When configuring, just weigh the ingredients according to the above ratio; first mix deionized water and butano...

Embodiment 3-5

[0112] Embodiments 3-5 all relate to a fabric antistatic finishing process, which is completed on the hot air stenter setting and the spray type antistatic finishing device of Embodiment 1. Based on Embodiment 2, the difference from Embodiment 2 is only : The heat setting temperature is different, and the formula of the antistatic finishing liquid used is different. The specific differences are shown in Table 2.

[0113] Table 2. Embodiment 3-5 stereotypes temperature and antistatic finishing solution formula table

[0114]

[0115] The polyester staple fiber wool-like fabrics finished according to the process methods of Examples 2-5 were respectively sampled for performance testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com