Conductive washing machine foot pad rubber, washing machine foot pad and washing machine

A washing machine and foot pad technology, which is applied in the fields of washing machine foot pad rubber, washing machine foot pad and washing machine, can solve the problems of unfavorable foot pad cushioning and shock resistance, unable to meet the requirements of foot pad flexibility and foot pad hardness, etc. The effect of safety, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0060] The present invention also provides a method for preparing the above-mentioned conductive washing machine foot pad rubber, comprising the following steps:

[0061] S1, plasticizing synthetic rubber;

[0062] S2, adding conductive carbon black and rubber molding additives, and mixing;

[0063] S3. Calendering, extrusion molding, vulcanization, and sheet production according to the required thickness and size.

[0064] In one embodiment, 100 parts by volume of butyl rubber is added to a plastic mixer for mastication for 8 minutes; then 124.4 parts by volume of conductive rubber, 15 parts by volume of aromatic oil, 1.5 parts by volume of rubber accelerator, 2.5 parts by volume of vulcanizing agent, 3 parts by volume of antioxidant, 3 parts by volume of coumarone resin, 2.5 parts by volume of stearic acid, 5.5 parts by volume of zinc oxide, kneading for 10min; calendering, extrusion molding, vulcanization, as required The thickness and size of the film.

Embodiment 7

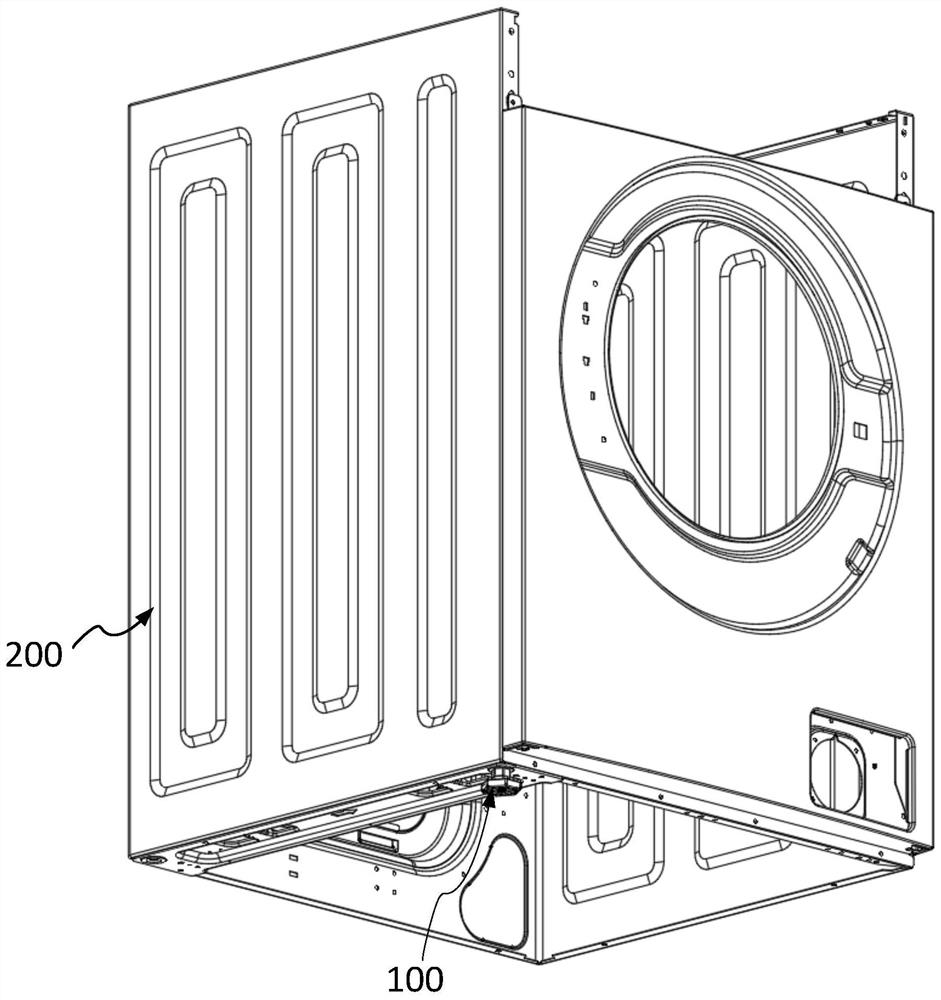

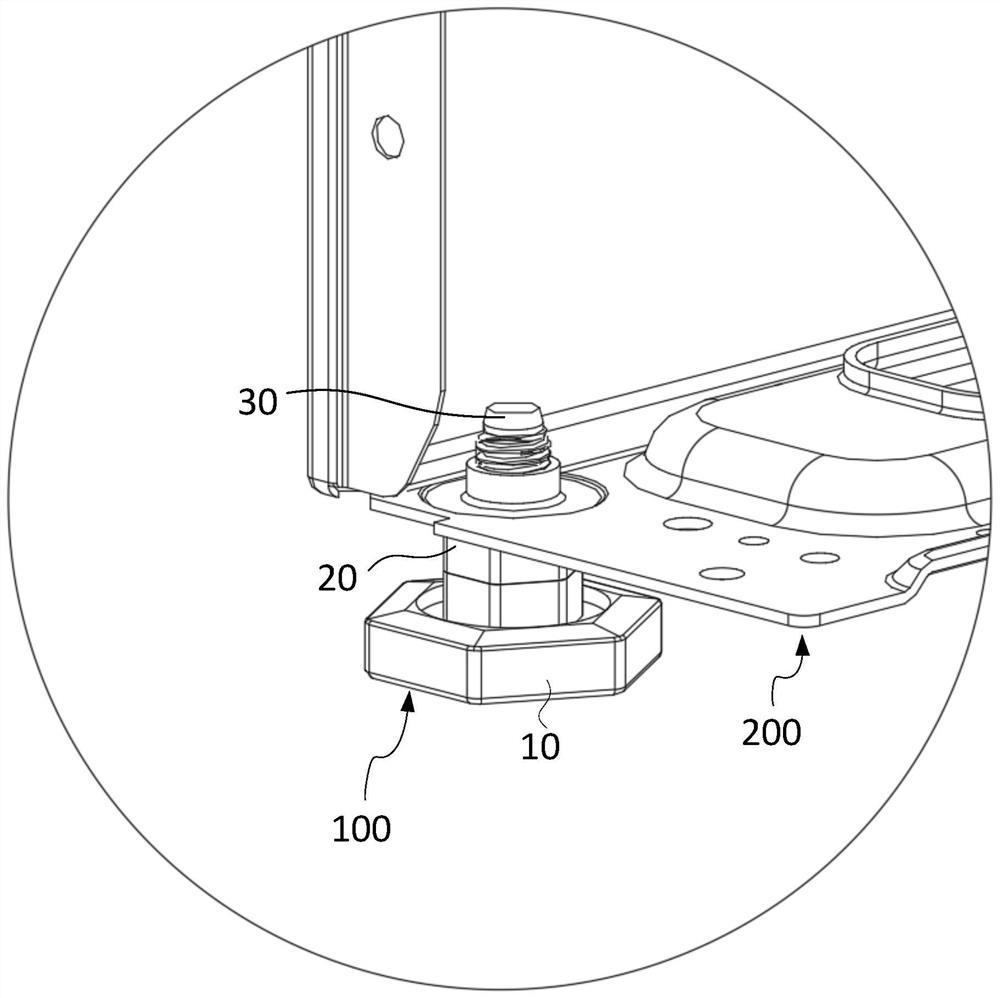

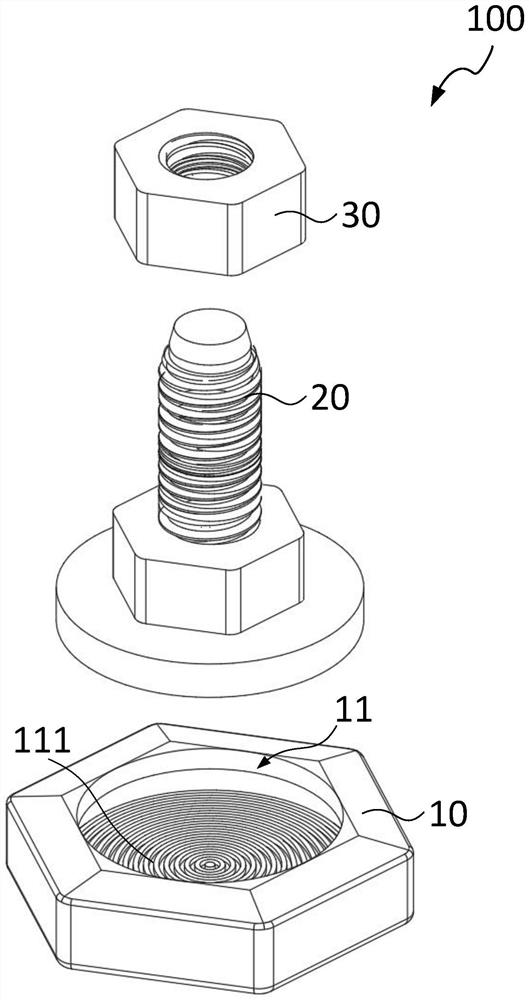

[0066] Such as figure 1 , figure 2 As shown, the present invention provides a washing machine foot pad, including a foot pad body 100 arranged at the bottom of the washing machine cabinet 200, and the foot pad body 100 includes a rubber bottom made of conductive washing machine foot rubber as described above Support 10, a fixing part, the fixing part has conductivity, and the fixing part is respectively connected to the rubber bottom support 10 and the washing machine cabinet 200; wherein,

[0067] After the rubber bottom bracket 10 bears the gravity of the washing machine cabinet 200, the conductive carbon black particles in the rubber bottom bracket 10 approach each other to form a conductive path for electrical conduction with the washing machine cabinet 200. One side of the rubber bottom bracket 10 is used to support on the ground. In order to make the washing machine box 200 conduct electricity with the ground. It should be understood that the electrical conduction of ...

Embodiment 8

[0073] Such as figure 1 , figure 2 As shown, the present invention provides a washing machine, which includes a washing machine box 200, and at least four foot pad bodies 100 as described above are arranged at the bottom of the washing machine box 200, so as to realize the connection between the washing machine box 200 and the ground. electrical conduction.

[0074] In one embodiment, the washing machine box 200 is in the shape of a cuboid, and the number of the foot pad bodies 100 is four, which are respectively arranged at four corners of the bottom of the washing machine box 200 . After installing the washing machine, try running the washing machine. If the washing machine shakes, it means that the installation is not level. Adjust the adjusting nut 30 of the floor mat body 100. For example, the left front of the washing machine cabinet 200 is short, adjust the adjusting nut 20 of the left front mat body 100 so that the adjusting nut 20 is slightly away from the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com