Composite coating and application thereof

A coating and raw material technology, applied to combined coatings and their application fields, can solve the problems of difficult matrix bonding and poor adhesion of silicone coatings, achieve good adhesion effects, reduce processing costs and operation difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

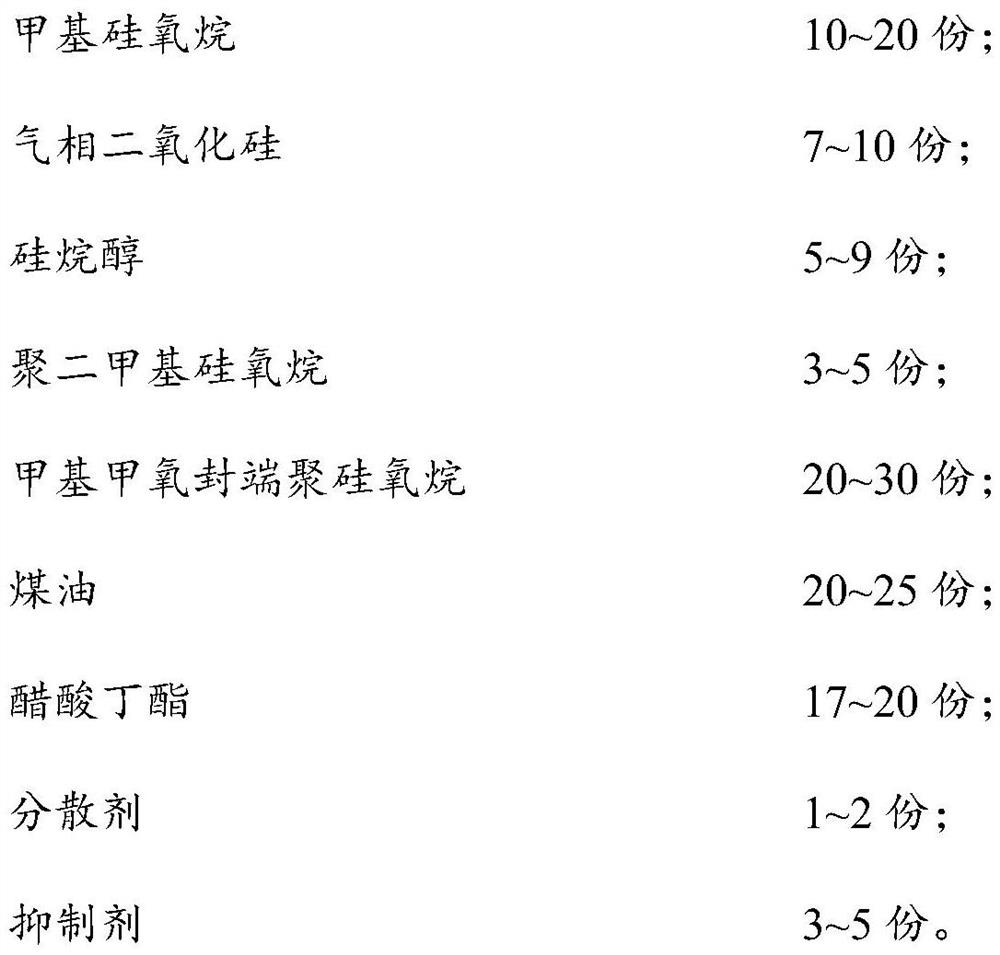

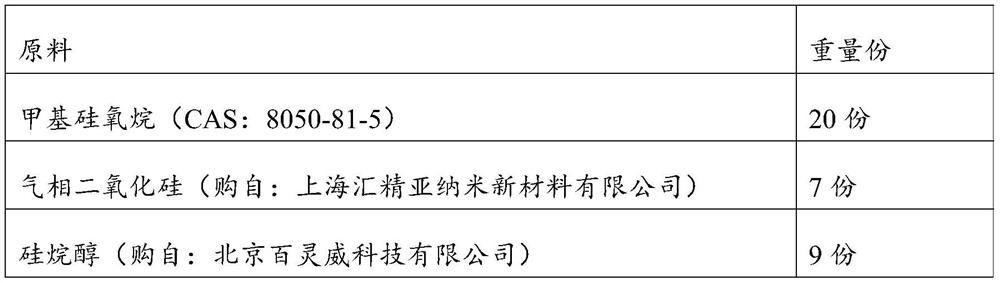

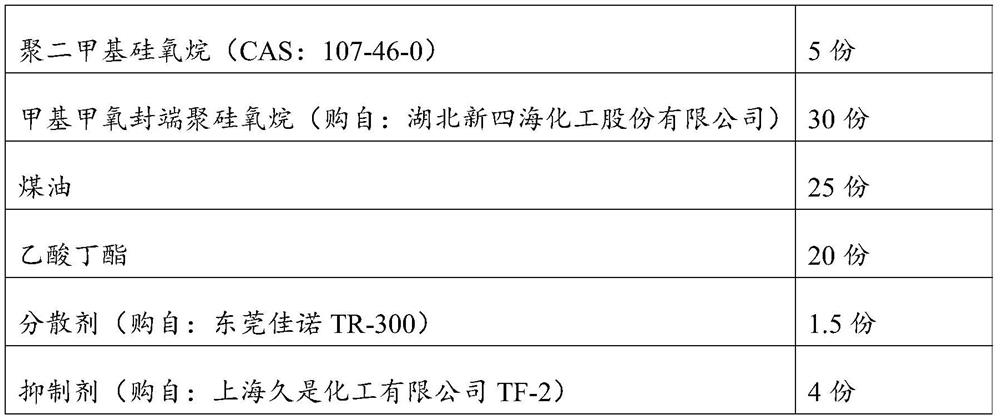

[0054] This embodiment provides a combined coating, wherein the components of the substrate treatment agent are shown in Table 1; the components of the silica gel coating are shown in Table 2.

Embodiment 2

[0056] The present embodiment provides a kind of combination paint, and wherein the difference with embodiment 1 is:

[0057] The components of the substrate treatment agent are different, and the specific components are shown in Table 3;

[0058] Table 1 by weight, the raw material component distribution ratio of substrate treatment agent in embodiment 1

[0059] raw material parts by weight Toluene (CAS: 108-88-3) 40 copies Xylene (CAS: 1330-20-7) 30 copies Amorphous polyester 35 copies

[0060] Table 2 is by weight, the raw material component distribution ratio of silica gel coating in embodiment 1

[0061]

[0062]

[0063] Table 3 is by weight, the raw material component distribution ratio of substrate treatment agent in embodiment 2

[0064] raw material parts by weight Butanone (CAS: 78-93-3) 40 copies Cyclohexanone (CAS: 108-94-1) 30 copies Amorphous polyester 35 copies

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com