Method and system for improving stability of needle coke production process

A production process and production method technology, which is applied in the field of needle coke production process stability control, can solve the problems of inability to ensure the proper operating range of the pressure control system, wide adjustment range of the pressure control system at the top of the tower, and large fluctuations in the processing capacity of the fractionation system. problems, to achieve the effect of stabilizing control, eliminating adverse effects, and reducing the operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

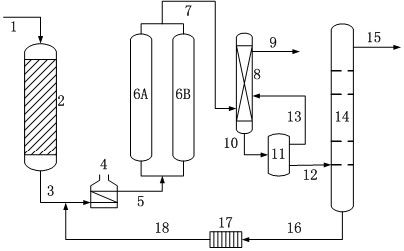

Method used

Image

Examples

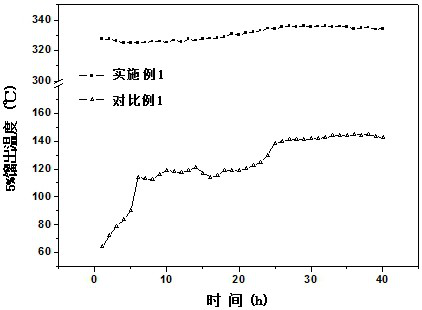

Embodiment 1

[0062] Example 1 Using the method provided by the present invention, the desolidified catalytic oil slurry is mixed with hydrogen and enters the hydrogenation reaction zone. The hydrogenation catalyst brand is FZC-34 (developed by Fushun Petrochemical Research Institute), and the hydrogenation treatment conditions are: The reaction temperature is 385°C, the reaction pressure is 8MPa, the volume ratio of hydrogen to oil is 1000, and the liquid hourly space velocity is 0.8h -1 ; The obtained hydrotreated oil is sent to the delayed coking reaction system, the outlet temperature of the heating furnace is 450°C-510°C, the coke tower adopts pressure swing operation, and the initial pressure at the top of the tower is 1.2MPa. When the feed time reaches 60% of the reaction cycle , the pressure at the top of the tower drops to 0.2 MPa at a rate of 0.5MPa / h, and the reaction period is 40h; the coked oil gas generated by the reaction is sent to the pressure stabilizing tower, the light co...

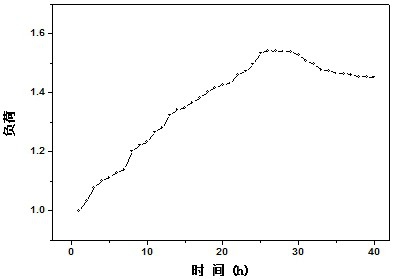

Embodiment 2

[0064] Example 2 adopts the method provided by the present invention, and the operating conditions are basically the same as those in Example 1, except that the coke drum is operated at a constant pressure of 0.8 MPa. During the whole reaction cycle, the load of the fractionation tower is as follows Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com