Tough wear-resistant strengthened layer and preparation method thereof

A strengthening layer and strong toughness technology, which is applied in coating, metal material coating process, etc., can solve the problems of poor toughness of coating, complex process, and difficulty in industrialization implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

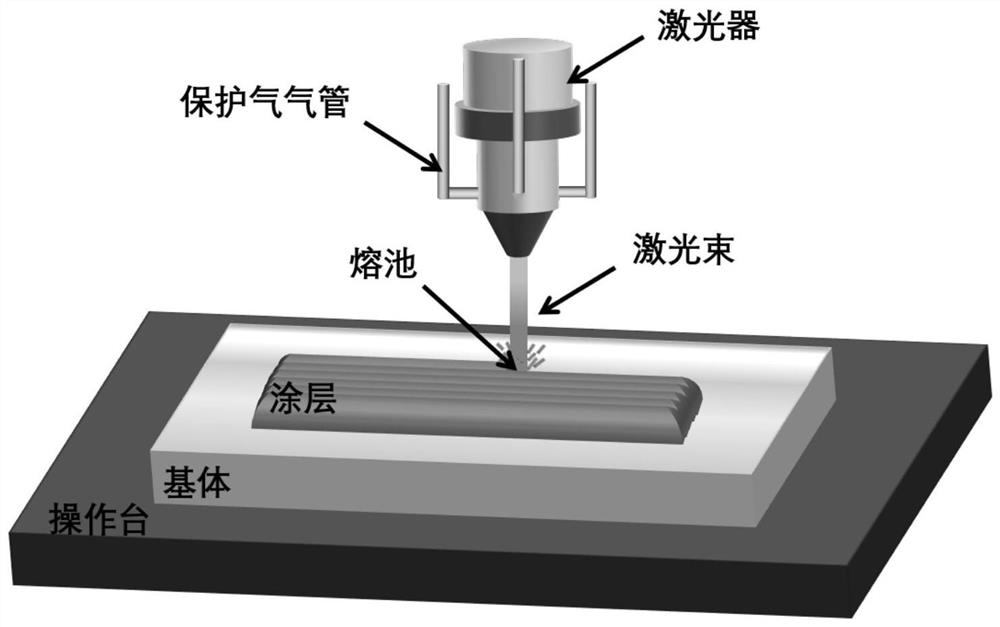

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Powder preparation

[0030] Raw materials for laser cladding are divided into medium-entropy alloy powder and strengthening phase powder. The selected medium-entropy alloy Ni, Co, and Cr powders have a particle size of 45-75 μm, and the powder ratio is the molar ratio Ni:Co:Cr=1:1: 1. The particle size of WC powder in the strengthening phase is 35-45 μm, and the particle size of TiC, ZrC, NbC, VC, etc. is 10-20 μm. According to the mass ratio of the powder, the medium entropy alloy powder is 80%, the ceramic powder is 20%, and the WC powder accounts for 100% in the ceramic powder, and the rest TiC, ZrC, NbC, VC, etc. account for 0%.

[0031] Step 2: Substrate surface pretreatment

[0032] First, use a grinding wheel to grind the surface of 24CrNiMo steel to remove oil and oxides and increase the roughness. If it is not cleaned and used directly, it will affect the quality of cladding, then degrease with absolute ethanol and dry in the air. During the grinding ...

Embodiment 2

[0038] In addition to the powder preparation in step 1, the medium entropy alloy powder is 50%, the ceramic powder is 50%, and the WC powder accounts for 80% in the ceramic powder, and the remaining TiC accounts for 20%. The thickness of the laser cladding powder in step 3 is 10mm; Run the laser cladding equipment, the experimental parameters used are: laser power is 1500W, scanning speed is 7mm / s, and the average surface hardness of the sample after treatment in step 4 hardness and friction and wear test can reach 900HV 0.1 , the friction and wear test was carried out on the sample, and the wear volume loss was 0.3×10 8 μm 3 , coating abrasion resistance is more than 3 times of substrate, and all the other are identical with embodiment one.

Embodiment 3

[0040] Except step 1 powder preparation, medium entropy alloy powder is 65%, ceramic powder is 35%, and WC powder accounts for 90% in ceramic powder, and all the other VC accounts for 10%, other is the same as embodiment two. Carry out hardness and friction and wear tests on the sample, and the average surface hardness of the sample after treatment can reach 1100HV 0.1 , the wear volume loss is 0.2×10 8 μm 3 , The wear resistance of the coating is 5 times that of the substrate.

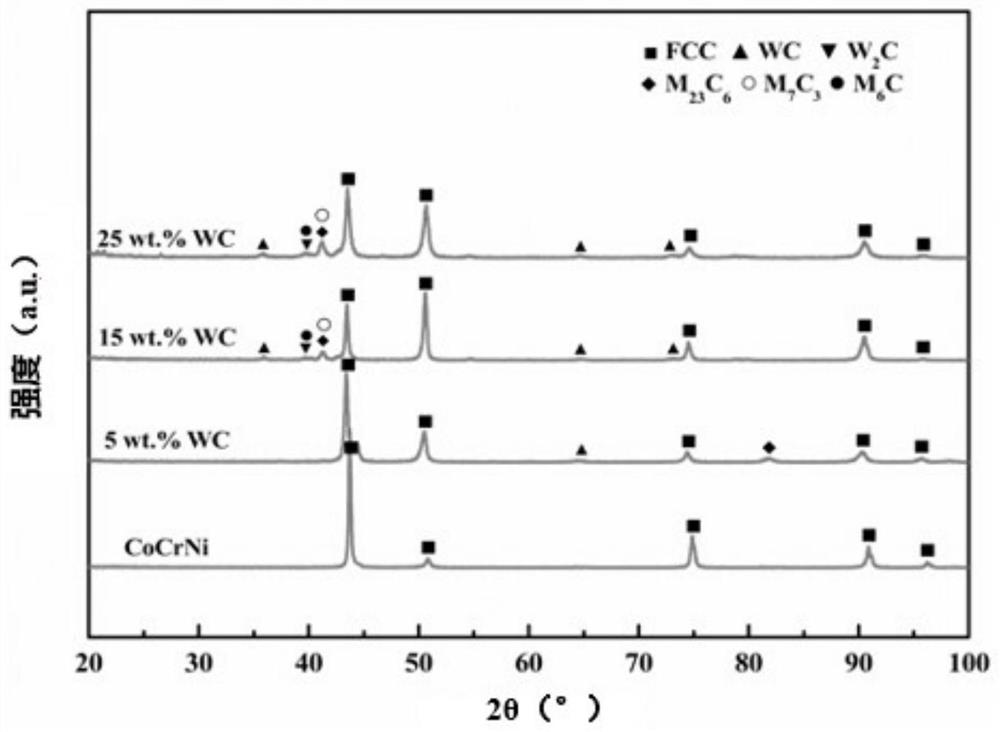

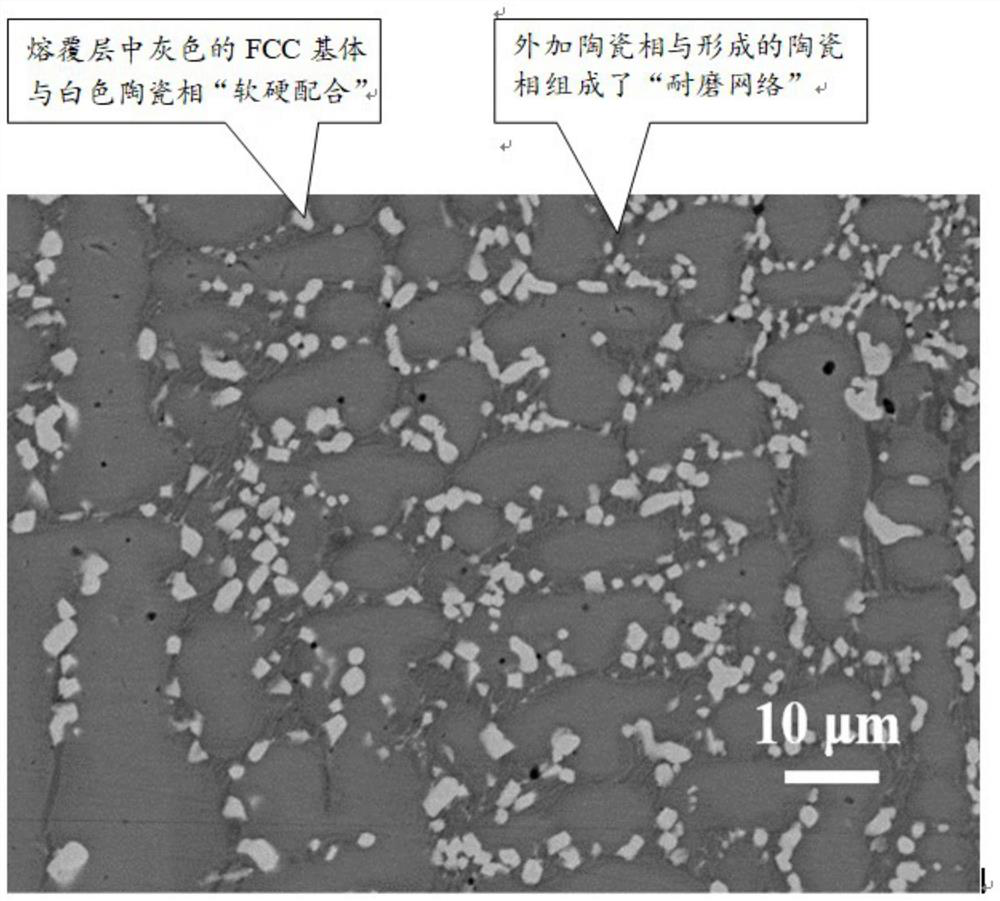

[0041] figure 2 It is a phase composition diagram of the cladding layer of the present invention, which shows the phase composition of the cladding layer with the addition of WC powder in the system being 25wt%. It can be seen from the figure that under suitable laser process parameters, the WC particles Partially dissolves, decomposes to different degrees, and forms W with hardness between WC and FCC matrix 2 C.M 23 C 6 , M 7 C 3 , M 6 C and other compounds. For the sake of comparison, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com