Method for preparing super-hydrophobic polyester fabric based on thiol-ene click reaction

A polyester fabric, super-hydrophobic technology, applied in textiles and papermaking, liquid repellent fibers, fiber treatment, etc., can solve the problems of complex preparation process and long preparation time, and achieve good selectivity, simple operation, and time-consuming. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

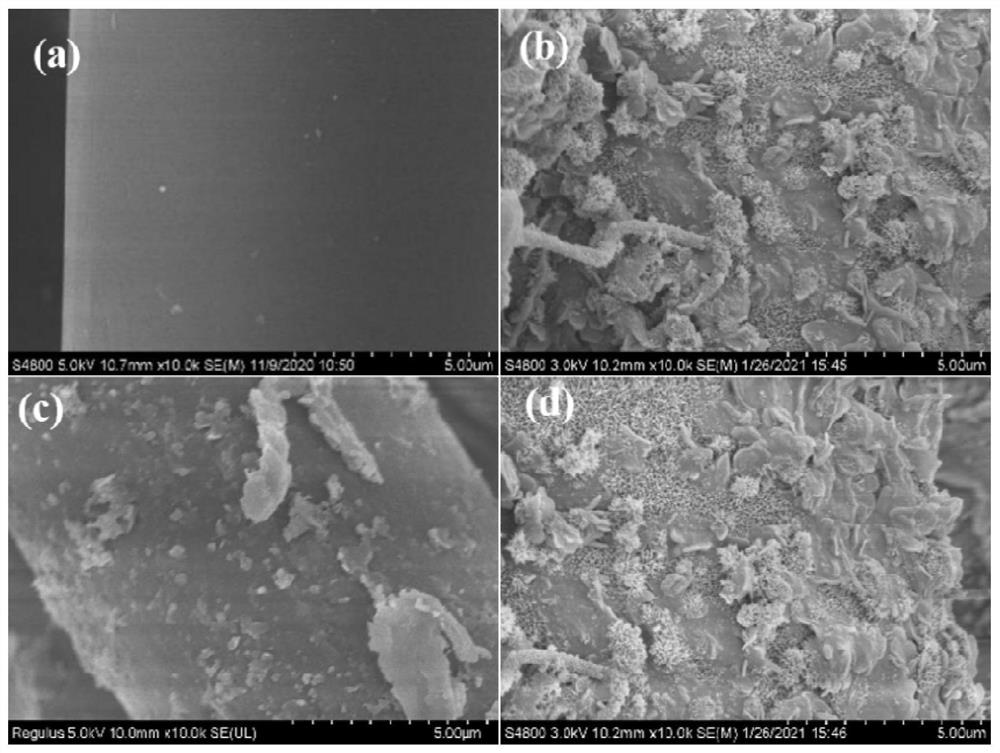

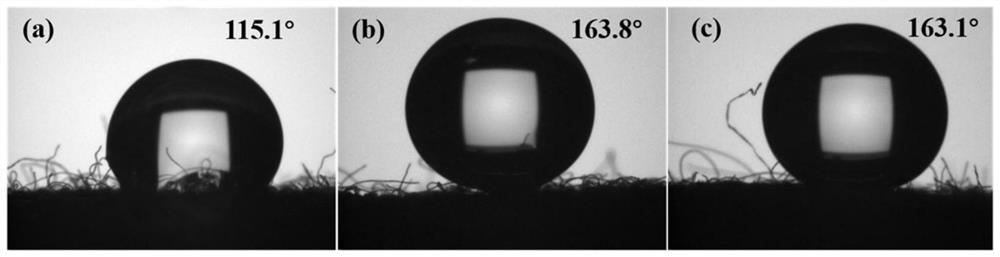

[0039] a) Adhesion of polyphenols: according to the bath ratio of 1:200, soak the cleaned polyester fabric in an aqueous solution containing eugenol (1g / L), vibrate at 80°C for 15min, and then roll out the excess polyphenols with a paddle car. solution to obtain polyphenol-adhered polyester fabrics.

[0040] b) Complexation of ions: prepare an aqueous solution of ferrous sulfate heptahydrate (6g / L), add polyphenol-adhered polyester fabric to react for 60 minutes according to the bath ratio of 1:200, and squeeze out excess solution to obtain ion-complexed polyester fabric.

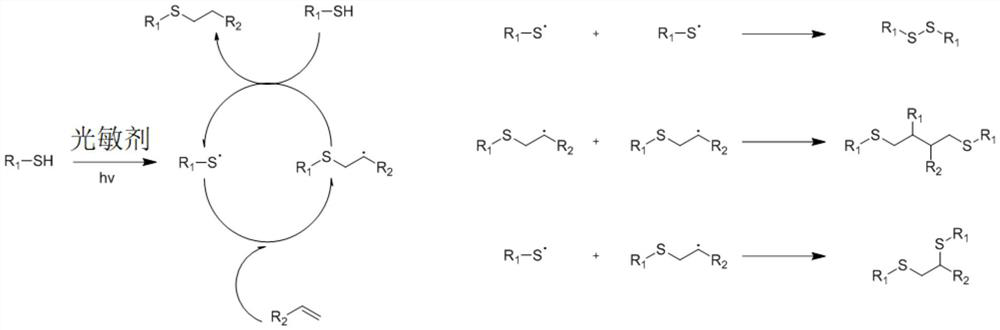

[0041] c) Surface click chemistry: prepare an ethanol solution containing n-octearyl mercaptan (1.75g / L) and benzoin (1g / L), sonicate for 10min until n-octadecyl mercaptan is completely dissolved, and add it at a bath ratio of 1:100. deionized water, and stir evenly to obtain a treatment liquid. Pour the treatment solution on the surface of the ion-complexed polyester fabric obtained in step b) until it has...

Embodiment 2

[0045] a) Adhesion of polyphenols: According to the bath ratio of 1:150, soak the cleaned polyester fabric in an aqueous solution containing chlorogenic acid (3g / L), shake it at 75°C for 15min, and then roll out the excess solution to obtain polyphenol-adhered polyester fabrics.

[0046] b) Complexation of ions: prepare an aqueous solution of ferrous sulfate heptahydrate (3g / L), add polyphenol-adhered polyester fabric to react for 30 minutes according to the bath ratio of 1:150, and squeeze out excess solution to obtain ion-complexed polyester fabric.

[0047] c) Surface click chemistry: Prepare an ethanol solution containing n-octadecyl mercaptan (3g / L) and benzoin dimethyl ether (0.5g / L), sonicate for 10min until n-octadecyl mercaptan is completely dissolved, and use a 1:100 bath Then add deionized water and stir evenly to obtain the treatment liquid. Pour the treatment solution on the surface of the ion-complexed polyester fabric obtained in step b) until it has just cove...

Embodiment 3

[0051] a) Adhesion of polyphenols: According to the bath ratio of 1:100, soak the cleaned polyester fabric in an aqueous solution containing eugenol (3g / L), shake it at 80°C for 10min, and then roll out the excess polyphenols with a paddle car. solution to obtain polyphenol-adhered polyester fabrics.

[0052] b) Complexation of ions: prepare anhydrous ferric chloride (5g / L) aqueous solution, according to the bath ratio of 1:100, add polyphenol-adhered polyester fabric to react for 60 minutes, and squeeze out excess solution to obtain ion-complexed polyester fabric.

[0053] c) Surface click chemistry: Prepare an ethanol solution containing n-stearyl mercaptan (5g / L) and benzoin ethyl ether (0.2g / L), ultrasonicate for 10min until n-stearyl mercaptan is completely dissolved, and add in a bath ratio of 1:50 deionized water, and stir evenly to obtain a treatment solution. Pour the treatment solution on the surface of the ion-complexed polyester fabric obtained in step b) until i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com