Compact opto-electric probe

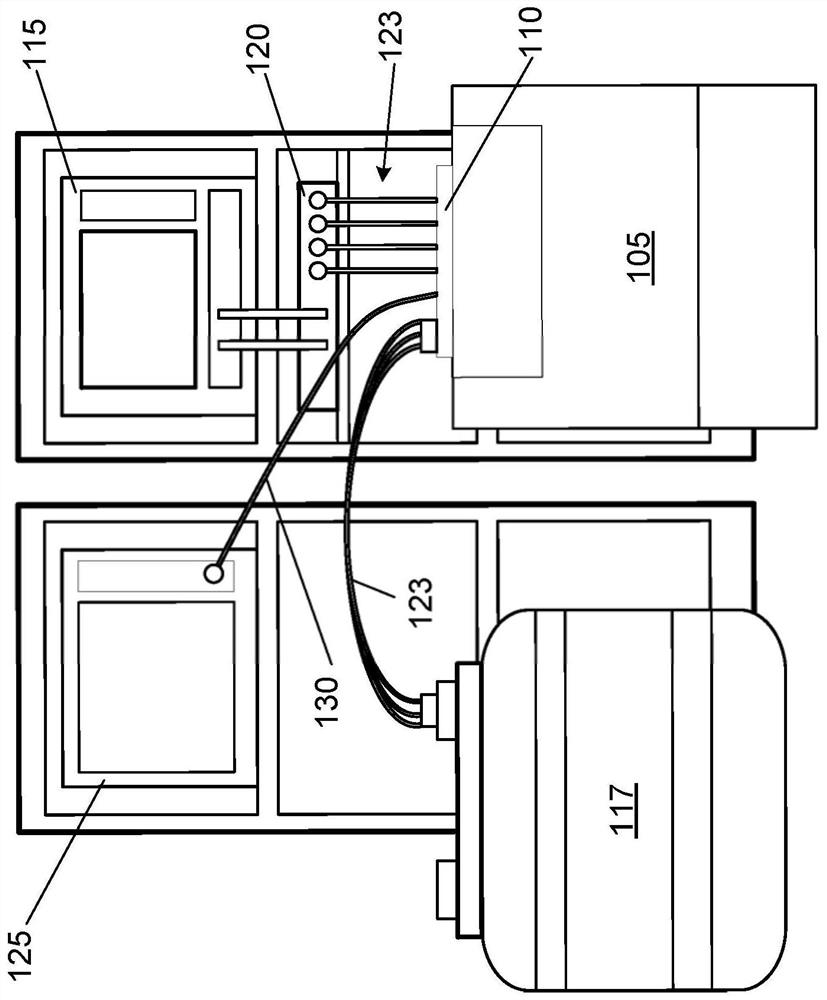

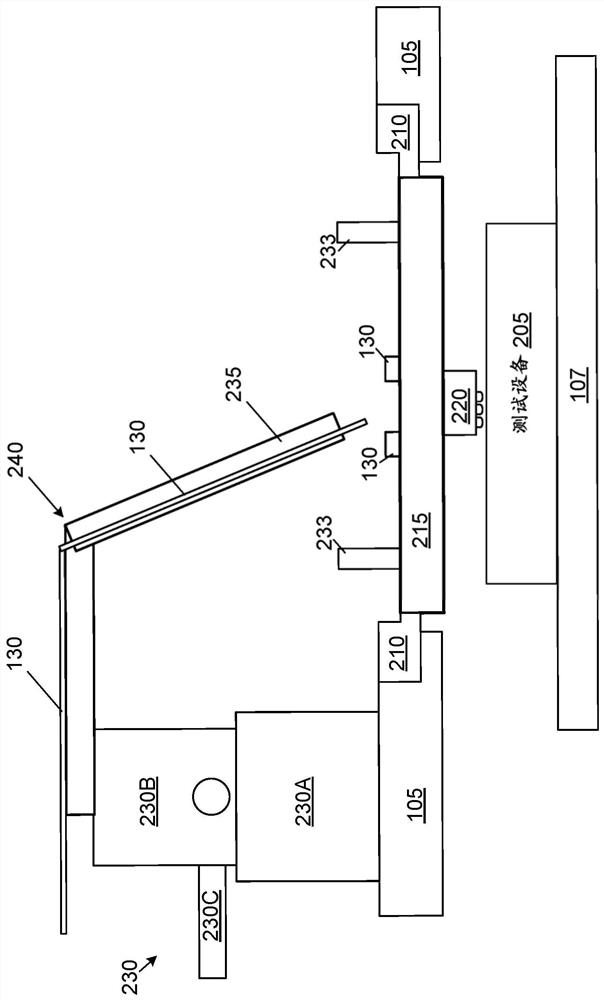

A photodetector and optoelectronic technology, applied in the field of optical and electrical interface systems, can solve problems such as difficult mixing of optical and electrical wafer wafer level testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

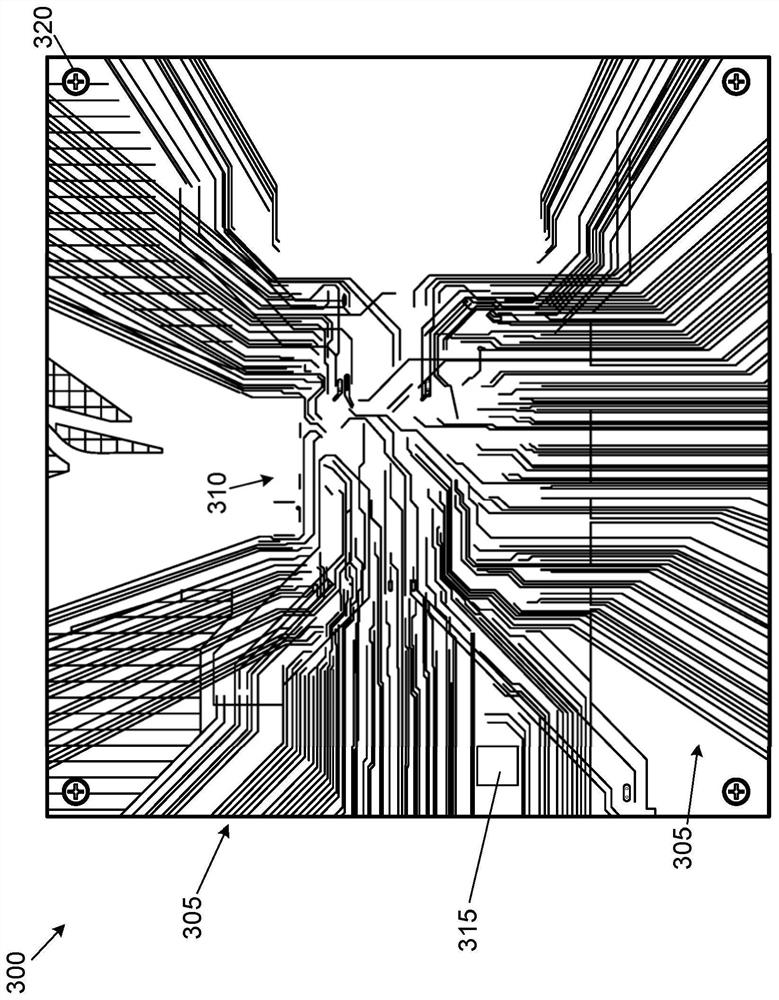

[0045] Example 1. A photodetector for interfacing with an optoelectronic device, the photodetector comprising: an electrical layer having electrical paths, at least some of which are connected to electrical terminals configured to interface with the optoelectronic an electrical component of the device is interfaced, the electrical path avoiding the optical path formed in the electrical layer; and an optical interface is used to interface with the optical component of the optoelectronic device, the optical interface is arranged to pass through the optical path formed in the electrical layer and Optical components for optical communication.

example 2

[0046] Example 2. A photodetector according to example 1 comprising a flexible optical fiber to allow positioning of the photodetector into an operative position in which the electrical terminals are in electrical contact with the electrical contacts of the optoelectronic device and the optical interface is in contact with Optical components are optically aligned.

example 3

[0047] Example 3. The photodetector according to any one of examples 1 or 2, wherein the electrical layer comprises a film comprising electrical paths, and wherein the electrical terminals extend from the film to corresponding electrical contacts of the optoelectronic device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com