Shielded integrated reactor and preparation method thereof

A reactor and reactor container technology, applied in the field of nuclear reactors, can solve problems affecting the application of small reactors, and achieve the effects of being beneficial to weight reduction, improving shielding performance, and reducing central leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

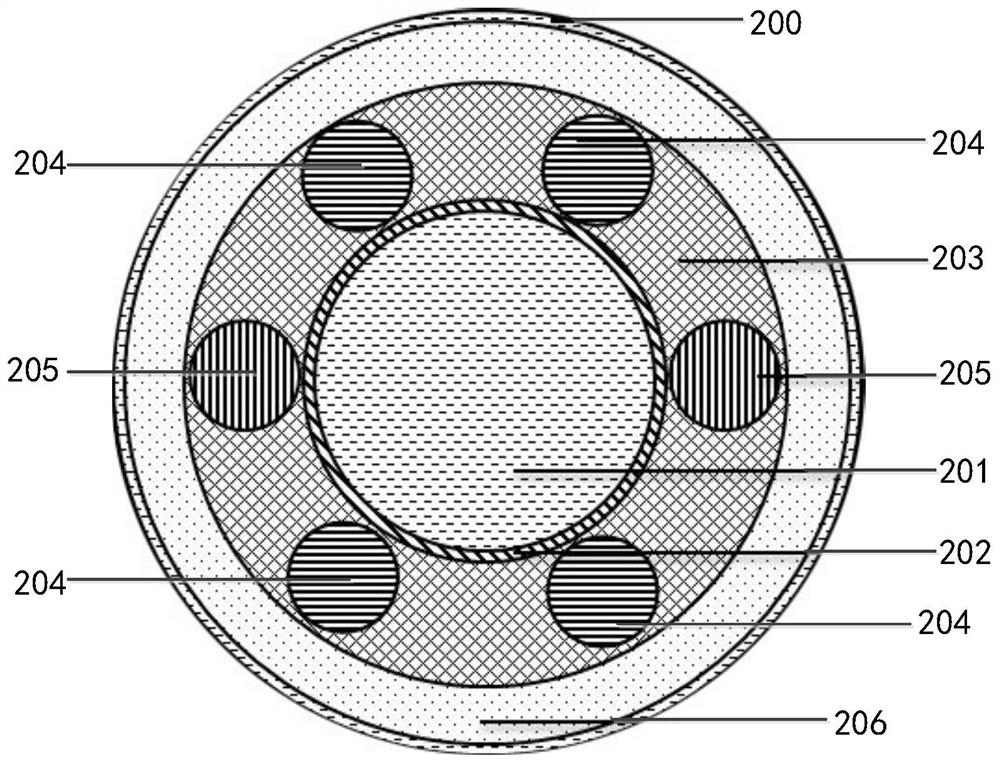

[0034] Such as figure 1 As shown, a shielded integrated reactor in this embodiment includes a reactor vessel 200 and a core 201, a core shroud 202, an inner shield 203, a heat exchanger 204 and main pump 205, the core 201 is arranged in the core shroud 202, the in-core shielding body 203 is arranged around the core shroud 202, the in-core shielding body 203 and the A space for filling coolant 206 is reserved between the reactor vessels 200, the heat exchanger 204 and the main pump 205 are respectively arranged in the inner shield body 203 and communicate with the space respectively, the heat exchanger 204 and the The main pumps 205 respectively contain neutron absorbing materials. The core shroud 202 can be a cylindrical structure without upper and lower cover plates, and the heat exchanger 204 can be a cylindrical structure; the reactor vessel 200 can also be a U-shaped cylinder structure that can withstand relatively high pressure, and Double-layer structure can be used. ...

Embodiment 2

[0037] Such as figure 1 As shown, a shielded integrated reactor in this embodiment includes a reactor vessel 200 and a core 201, a core shroud 202, an inner shield 203, a heat exchanger 204 and main pump 205, the core 201 is arranged in the core shroud 202, the in-core shielding body 203 is arranged around the core shroud 202, the in-core shielding body 203 and the A space for filling coolant 206 is reserved between the reactor vessels 200, the heat exchanger 204 and the main pump 205 are respectively arranged in the inner shield body 203 and communicate with the space respectively, the heat exchanger 204 and the The main pumps 205 respectively contain neutron absorbing materials. The core shroud 202 can be a cylindrical structure without upper and lower cover plates, and the heat exchanger 204 can be a cylindrical structure; the reactor vessel 200 can also be a U-shaped cylinder structure that can withstand relatively high pressure, and Double-layer structure can be used. ...

Embodiment 3

[0047] The preparation method of the shielded integrated reactor of the present embodiment comprises the following steps:

[0048] S1, using stainless steel to roll several cylindrical shells, shielded inner shells and shielded outer shells, the inner diameter of the shielded inner shell is larger than the outer diameter of the core shroud 202, and the outer diameter of the shielded outer shell is smaller than the inner diameter of the reactor vessel 200 ;

[0049] S2, opening a number of through holes corresponding to the size of the cylindrical shells on the two connecting plates, welding one ends of the cylindrical shells to the through holes of one of the connecting plates, and at the same time, shielding the inner shell and one end of the shielding shell is also welded on the same connecting plate, so that several of the cylindrical shells are located between the shielding inner shell and the shielding shell;

[0050] S3, filling the gap formed by the shielding inner she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com