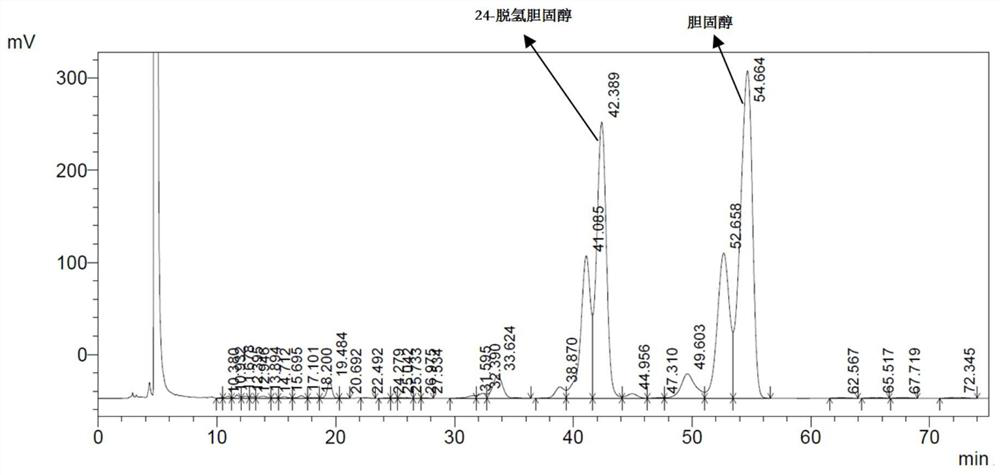

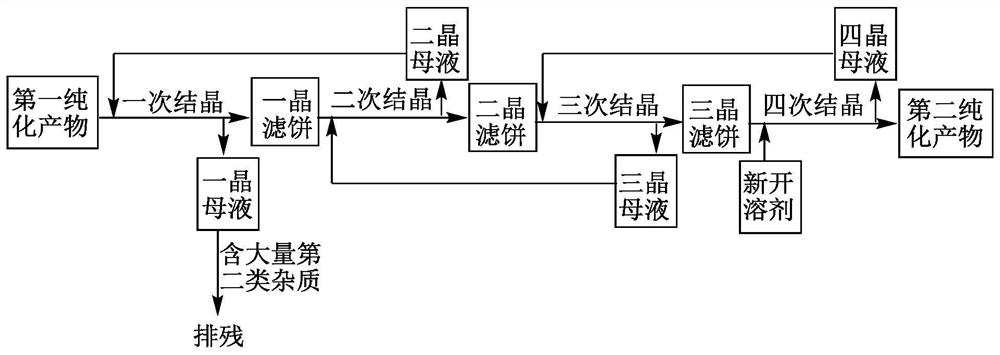

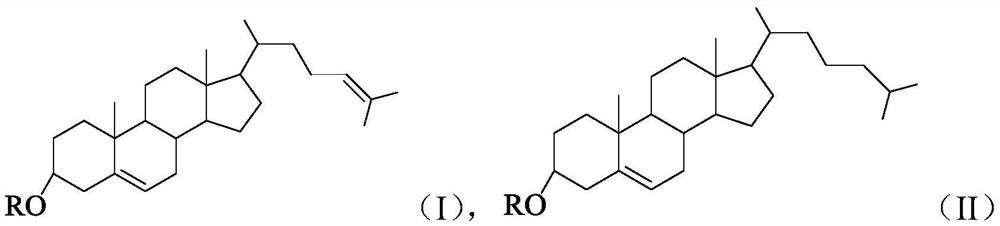

Method for purifying 24-dehydrocholesterol

A technology for dehydrocholesterol and compound, applied in the direction of organic chemistry, steroids, etc., can solve the problems of large solvent consumption, high cost, complicated process, etc., and achieve the effects of being conducive to industrialization, low environmental pressure, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1A) In a 3000mL reaction flask, add 300g lanolin cholesterol crystallization mother liquor concentrate (external standard content: the content of 24-dehydrocholesterol is 26.3wt%, the content of cholesterol is 42.5wt%), toluene 1500mL and bromine Calcium 150g, then heated up to 100°C, and kept at 100°C for complexation reaction for 1 hour, after the reaction was completed, the reacted material was cooled to 35°C within 3 hours, and the complex was obtained by filtration. Then add the obtained complex, 1000mL of toluene and 200mL of water into a 2000mL reaction flask, heat up to 65°C with stirring until it dissolves, leave it to separate and obtain an organic phase and an aqueous phase, and wash the organic phase with 200mL of water once. The organic phase was concentrated under reduced pressure to obtain 231.3 g of the first purified product (external standard content: the content of 24-dehydrocholesterol was 33.4 wt%, and the content of cholesterol was 54.3 wt%);

[...

Embodiment 2

[0075] (1A) In a 3000mL reaction flask, add 300g lanolin cholesterol crystallization mother liquor concentrate (external standard content: the content of 24-dehydrocholesterol is 26.3wt%, the content of cholesterol is 42.5wt%), ethyl acetate 1500mL successively , methanol 30g and calcium bromide 150g, then heated up to 65°C, and kept warm for complexation reaction for 2 hours, after the reaction was completed, the reacted material was evaporated to remove methanol at 70°C, and the temperature of the remaining material was cooled within 3 hours To 45 ° C, the complex was obtained by filtration. Then, add the obtained complex, 1000 mL of ethyl acetate and 200 mL of water into a 2000 mL reaction flask, heat up to 65 ° C under stirring until it dissolves, and leave to separate layers to obtain an organic phase and an aqueous phase, and then use 200 mL of Wash with water once. The organic phase was concentrated under reduced pressure to obtain 240.7 g of the first purified product...

Embodiment 3

[0079] (1A) In a 3000mL reaction flask, add 300g lanolin cholesterol crystallization mother liquor concentrate (external standard content: the content of 24-dehydrocholesterol is 20.4wt%, the content of cholesterol is 41.3wt%), n-octane 2000mL successively And 120g of zinc chloride, then heated up to 100°C, and kept at 100°C for complexation reaction for 2 hours. After the reaction was completed, the reacted material was cooled to 50°C within 3 hours, and the complex was obtained by filtration. Then, add the obtained complex, 1000 mL of ethyl acetate and 200 mL of water into a 2000 mL reaction flask, heat up to 65 ° C under stirring until it dissolves, and leave to separate layers to obtain an organic phase and an aqueous phase, and then use 200 mL of Wash with water once. The organic phase was concentrated under reduced pressure to obtain 235.4 g of the first purified product (external standard content: the content of 24-dehydrocholesterol was 25.6 wt%, and the content of cho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com