Return material temperature control system and method of household garbage pyrolysis treatment system

A technology of temperature control system and processing system, applied in the field of pyrolysis, can solve the problems of hysteresis coupling and explosion-proof safety, and achieve the effect of reducing oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

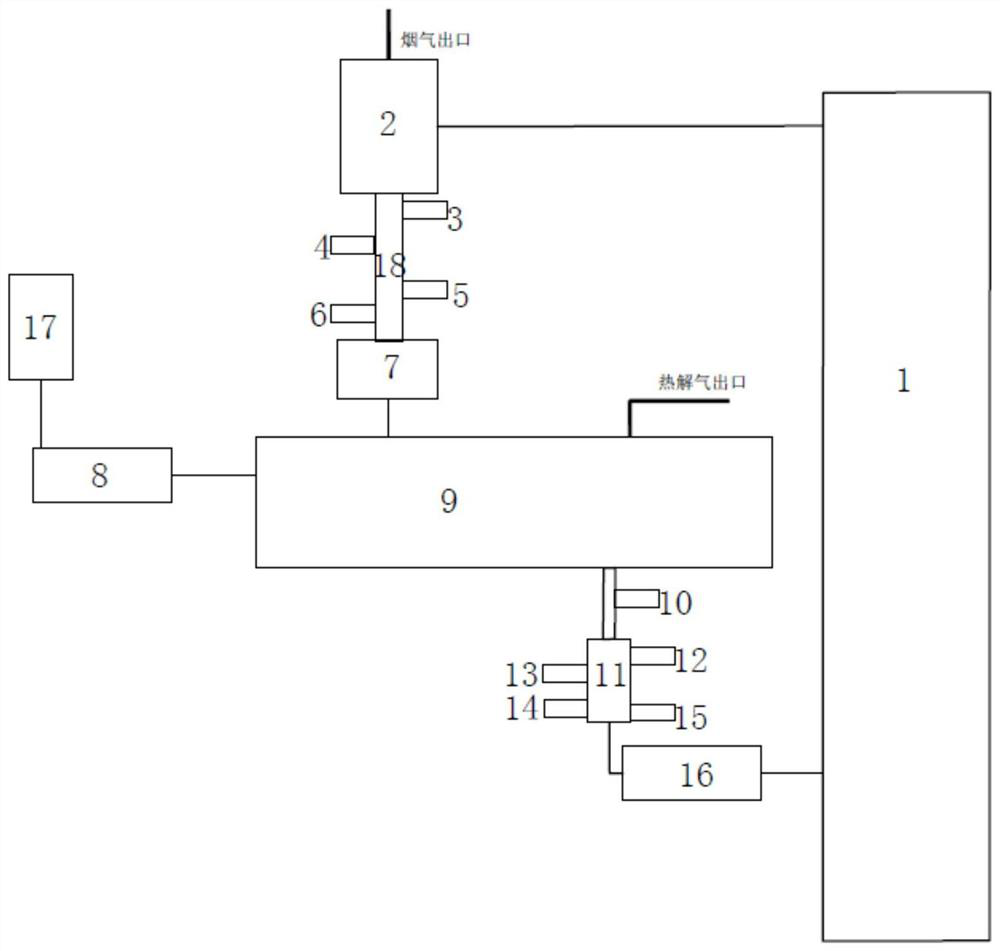

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The design of the technical scheme of the present invention is based on the following ideas: garbage and high-temperature heat carrier are mixed in the reactor, and the high-temperature heat carrier instantly raises the temperature of the garbage to N degrees, and the anaerobic environment of the reactor allows the garbage to be anaerobically decomposed into small molecules Gas, due to the high temperature of the reactor and a large amount of flammable gas environment, it is necessary to isolate the entry of oxygen to prevent the reactor from burning or exploding. Garbage will be fully pyrolyzed at a high enough temperature and for a long enough time, so the final temperature after pyrolysis (return temperature) can be used as a necessary condition for sufficient pyrolysis. The speed of garbage entering the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com