Medical optical glass preparation detection device and detection method

A technology of optical glass and detection device, applied in measurement devices, instruments and other directions, can solve the problems of omission, low yield rate and large workload, etc., and achieve the effect of improving detection efficiency, reducing workload and improving switching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technique of the present invention, the creation characteristics, the achievement and the efficiency are readily understood, and the present invention is further illustrated in connection with the present invention, and it is to be explained, and the embodiments in the present application are described below. The features in the examples can be combined with each other.

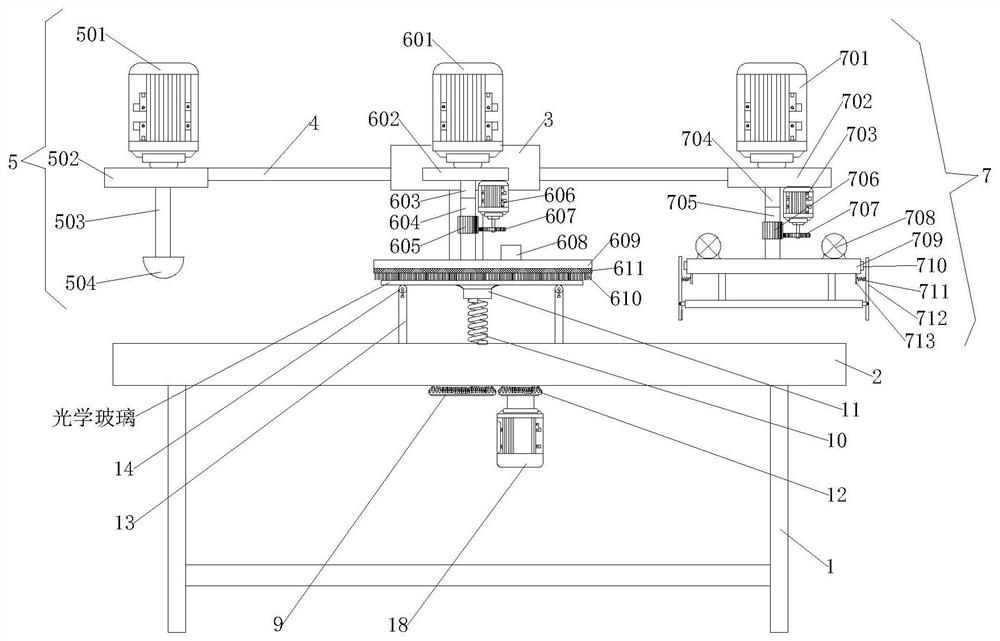

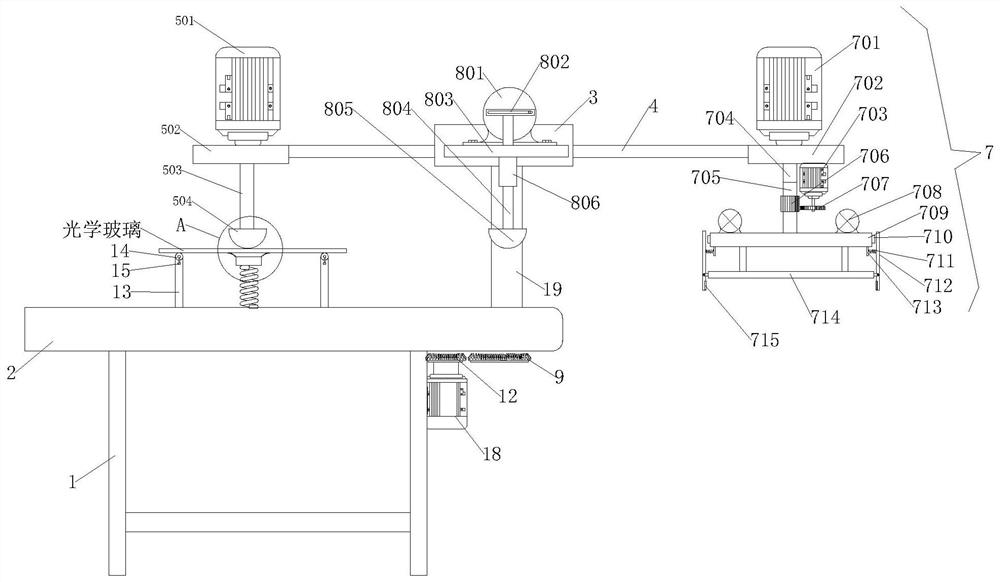

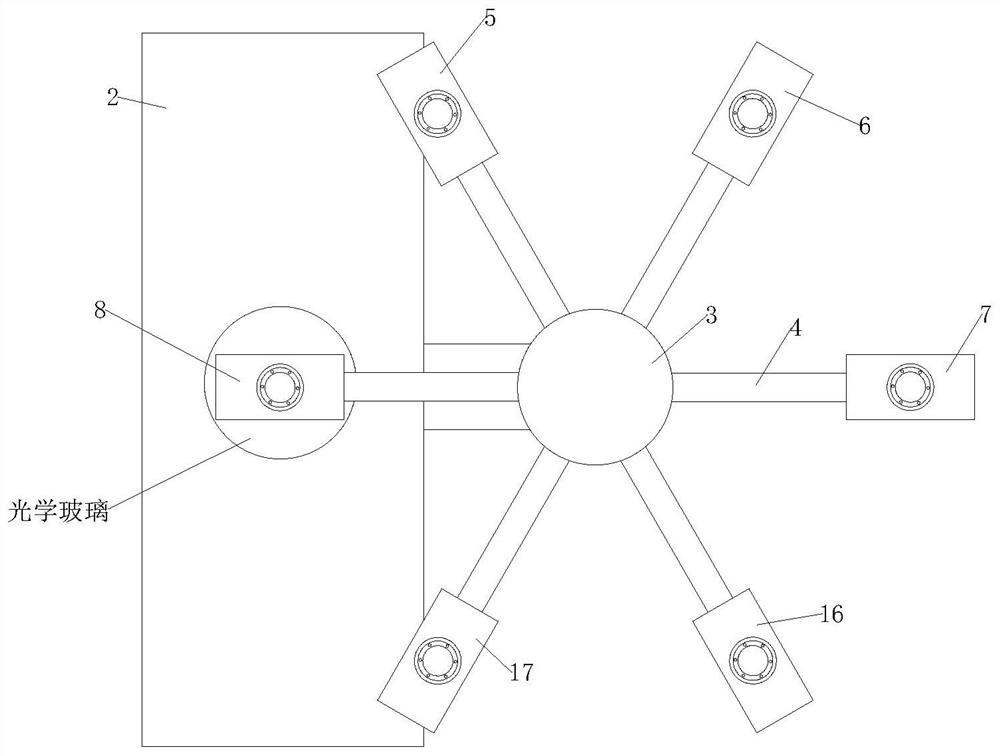

[0051] See Figure 1-11 A comprehensive structure of a medical optical glass preparation detection device and a detection method;

[0052] A medical optical glass preparation detecting device includes a table 2, a top surface of the table 2, and the bottom end of the table 2 is fixed with a support leg 1 in the bottom end of the table 2, and the top of the table 2 is solid A compressive suction cup 11 is provided with a top end of the table 2, and a central suction cup 11 is fixedly mounted, and the central suction cup 11 is disposed as a disc structure, the center suction cup 11 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com