Production method of peanut dried beancurd stick bag of Liuzhou river snails rice noodle

A production method and technology of snail powder, which is applied in the field of production of snail powder peanut yuba package, can solve the problems of high rotten rate and poor taste, and achieve the effects of convenient operation, extended shelf life and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

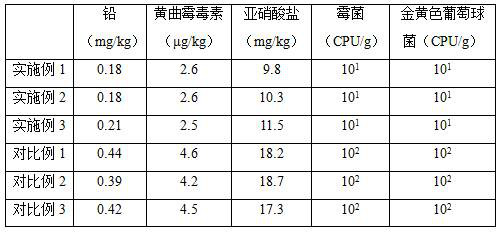

Examples

Embodiment 1

[0024] A kind of production method of snail powder peanut bean curd stick bag, it comprises the following steps:

[0025] (1) Select peanuts without insects and spots, shell the peanuts, and then perform color selection to remove impurities, then wash the selected peanut kernels with water for 3 times, and then microwave dry the peanut kernels. The microwave drying time is After 18 minutes, peanut kernels with a water content of 12% were obtained; the microwave power of microwave drying was 800W, and the temperature was 66°C;

[0026] (2) Mix the peanut kernels treated in step (1) with oil at room temperature, then stir-fry for 8 minutes at an oil temperature of 145°C, then cool naturally to obtain fried peanut kernels, and then carry out ultraviolet sterilization and put them Store in a nitrogen atmosphere for later use;

[0027] (3) Select soybeans with full grains, no mildew, no moths, and no diseases, and then perform color selection to remove impurities, and then wash th...

Embodiment 2

[0031] A kind of production method of snail powder peanut bean curd stick bag, it comprises the following steps:

[0032] (1) Select and select peanuts without insects and spots, shell the peanuts, and then perform color selection to remove impurities, then wash the selected peanut kernels with water twice, and then microwave dry the peanut kernels. The microwave drying time is 15min to obtain peanut kernels with a water content of 10%; the microwave power of microwave drying is 700W, and the temperature is 70°C;

[0033] (2) Mix the peanut kernels treated in step (1) with oil at room temperature, then stir-fry for 10 minutes at an oil temperature of 130°C, then cool naturally to obtain fried peanut kernels, and then carry out ultraviolet sterilization and put Store in a nitrogen atmosphere for later use;

[0034] (3) Select soybeans with full grains, no mildew, no moths, and no diseases, and then perform color selection to remove impurities, and then wash the selected soybea...

Embodiment 3

[0038] A kind of production method of snail powder peanut bean curd stick bag, it comprises the following steps:

[0039](1) Select peanuts without insects and spots, shell the peanuts, and then perform color selection to remove impurities, then wash the selected peanut kernels with water for 3 times, and then microwave dry the peanut kernels. The microwave drying time is 20min to obtain peanut kernels with a water content of 15%; the microwave power of microwave drying is 800W, and the temperature is 60°C;

[0040] (2) Mix the peanut kernels treated in step (1) with oil at room temperature, then stir-fry for 8 minutes at an oil temperature of 150°C, then cool naturally to obtain fried peanut kernels, and then sterilize them with ultraviolet light. Store in a nitrogen atmosphere for later use;

[0041] (3) Select soybeans with full grains, no mildew, no moth, and no disease, and then perform color selection to remove impurities, and then wash the selected soybeans with water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com