Magnesite electric energy light burning shaft kiln

A magnesite and light-burning technology, which is applied in the field of light-burning magnesia for refractory industry, can solve the problems of large thermal energy loss, large environmental pollution of light-burning shaft kilns, low production efficiency, etc., and achieves the effect of energy saving and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment technical scheme of the present invention will be further described:

[0025] In the description of the present invention, it should be noted that unless otherwise specified and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection. Connected, or integrally connected; either directly or indirectly through an intermediary. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

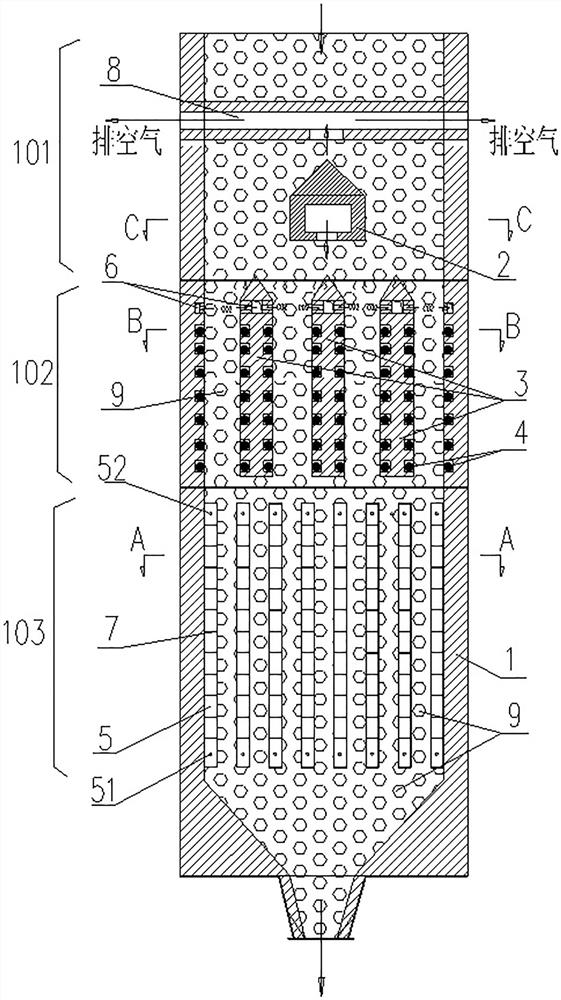

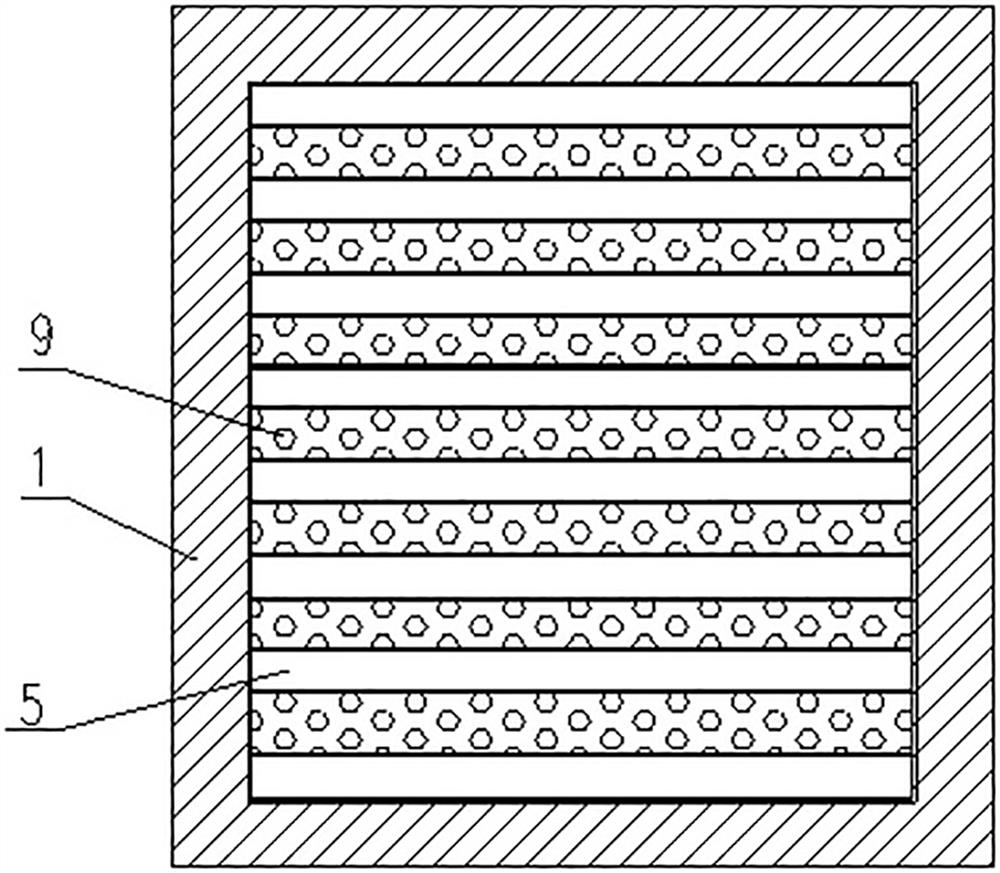

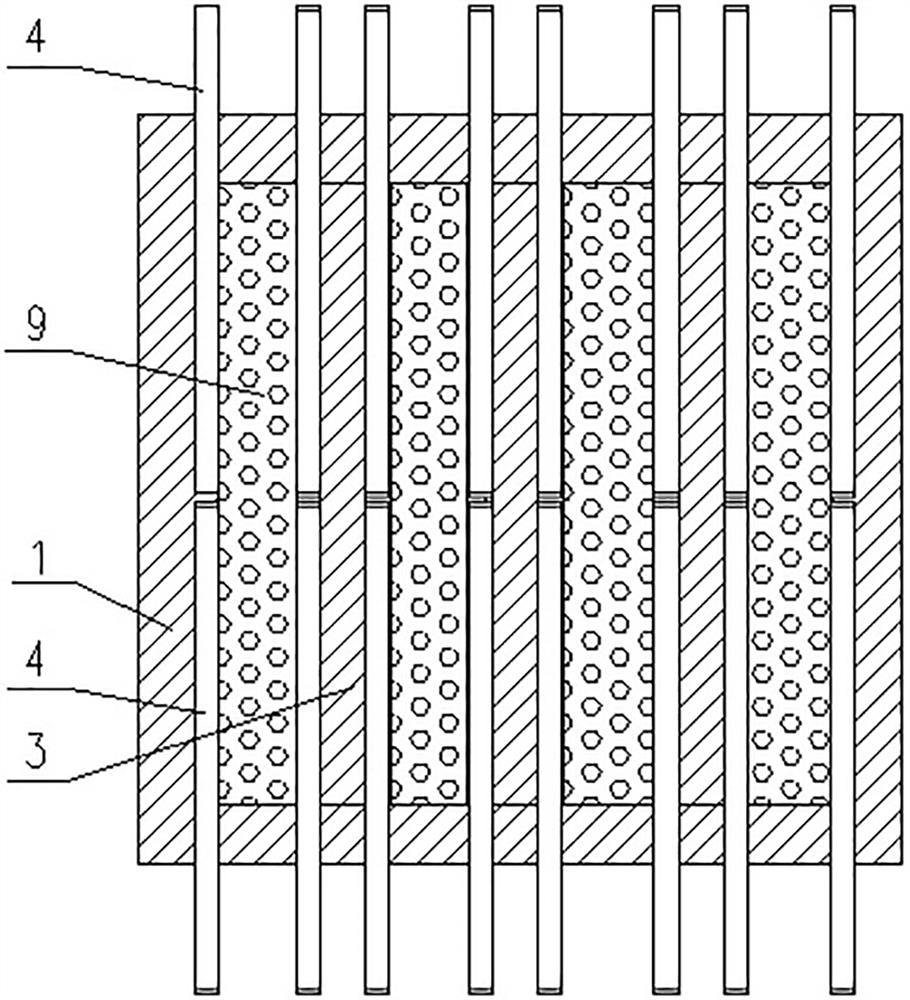

[0026] See Figure 1-Figure 4 , is a structural schematic diagram of an embodiment of a magnesite electric light-fired shaft kiln according to the present invention. The kiln body 1 is a rectangular section, which is divided into a pre-heating zone 101, a light-burning zone 102 and a cooling zone 103 from top to bottom. A preheating hollow beam 2 is set in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com