Expandable graphite hard polyurethane composite thermal insulation material and preparation method thereof

A composite thermal insulation material and rigid polyurethane technology, applied in the field of building thermal insulation and flame retardant materials, can solve the problems of unverified use effect, complex preparation process, neglect of thermal conductivity, etc., achieve simple and rapid processing technology, reduce heat transfer, and reduce raw materials cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

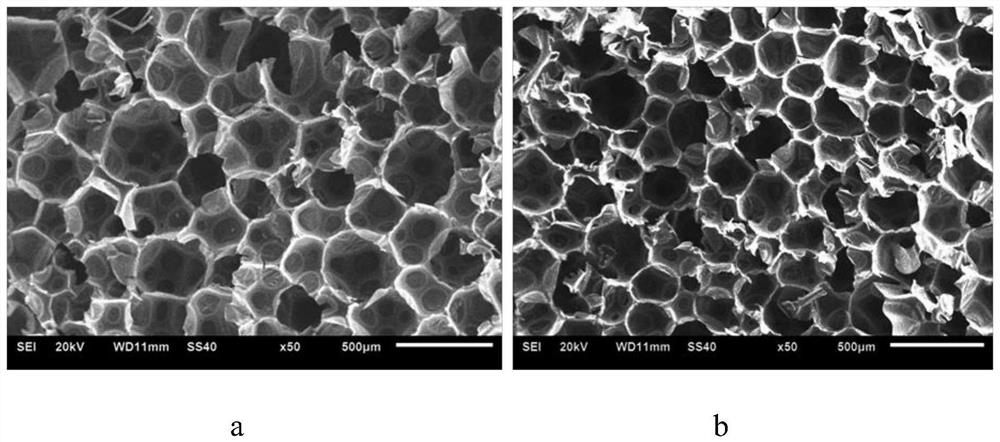

[0051] The preparation of airgel-expandable graphite rigid polyurethane composite insulation material comprises the following steps:

[0052] S1, SiO 2 The synthesis process of airgel consists of three steps.

[0053] The first step is gel preparation, the second step is aging and solvent exchange, and the third step is surface modification and gel drying. First add the water-glass mixture in deionized water at a volume ratio of 1:4. Then tartaric acid was slowly added to the mixture while stirring continuously until the pH of the mixture reached 4–5 and then stirred for 10 minutes. The resulting mixture was transferred to a sealed flask to form a gel, and the resulting gel was left to age for 4 hours. The aging process is to complete the gel formation reaction and improve the strength of the gel structure. In order to remove residual sodium ions, the resulting gel was washed 4 times every 6 h, and placed in isopropanol and n-hexane at 55 °C for 24 h, respectively. The su...

Embodiment 2

[0059] The preparation of airgel-expandable graphite rigid polyurethane composite insulation material comprises the following steps:

[0060] S1. The specific experimental process is the same as that of S1 in Example 1.

[0061] S2, first polyether polyol 4110A, SiO 2 The airgel and expandable graphite were dried in an infrared electric blast drying oven at 80°C for 24 hours to remove moisture.

[0062] S3. Add 6g of hard foam silicone oil AK158, 0.6g of triethylenediamine, 2g of deionized water, 3g of TCEP and 6g of DMMP to 100g of polyether polyol 4110A, and stir and mix at a speed of 1500 rpm for 20 minutes to obtain a polyol matrix.

[0063] S4, 4g SiO 2 Airgel and 15g of expandable graphite were sequentially added to 130g of polymeric isocyanate matrix, and after being fully stirred with a mechanical stirrer at a speed of 2000 rpm, the mixture was exposed to ultrasonic waves for 20-30 minutes to make the nanoparticles in the Uniformly dispersed in the matrix without a...

Embodiment 3

[0066] The preparation of airgel-expandable graphite rigid polyurethane composite insulation material comprises the following steps:

[0067] S1. The specific experimental process is the same as that of S1 in Example 1.

[0068] S2, first polyether polyol 4110A, SiO 2 The airgel and expandable graphite were dried in an infrared electric blast drying oven at 80°C for 24 hours to remove moisture.

[0069] S3. Add 8g of hard foam silicone oil AK158, 1g of triethylenediamine, 3g of deionized water, 3g of TCEP and 6g of DMMP to 100g of polyether polyol 4110A in sequence, and stir and mix for 20 minutes at a speed of 1500 rpm with a mechanical stirrer , to obtain a polyol matrix.

[0070] S4, 2g SiO 2 Airgel and 10g of expandable graphite were sequentially added to 130g of polymeric isocyanate matrix, and after being fully stirred with a mechanical stirrer at a speed of 2000 rpm, the mixture was exposed to ultrasonic waves for 20-30 minutes to make the nanoparticles in the Unifo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com