Uniform self-control gear heat treatment device and method based on asynchronous double-frequency induction heating

A dual-frequency induction and self-control technology, used in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of rough heating control method, poor heat treatment economy of gears, and expensive induction power supply, etc. The effect of uniformity and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

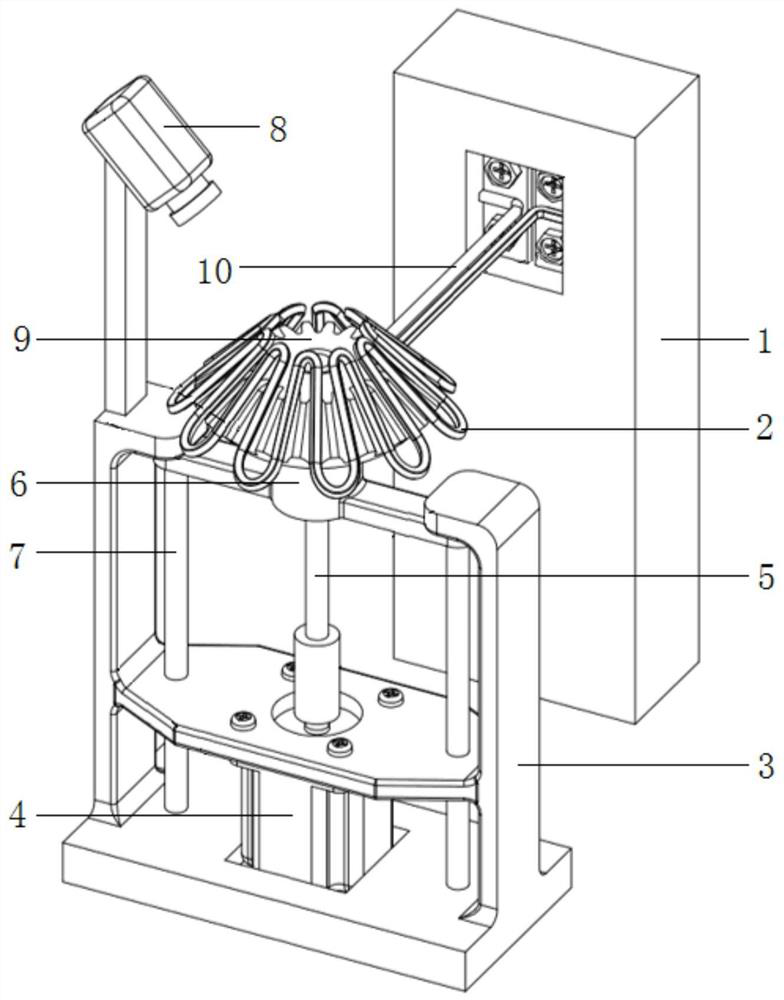

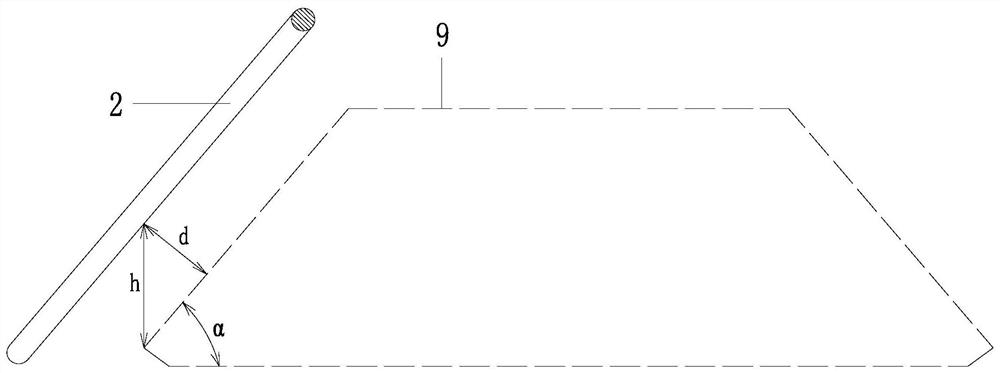

[0031] Such as Figure 1~3As shown, a uniform self-controlled gear heat treatment device based on asynchronous dual-frequency induction heating, including a power supply box 1, an induction coil 2, a bracket 3, a gear height adjustment motor 4, a lead screw 5, a screw nut slider 6, and a slider guide column 7. Infrared temperature measurement camera 8 and computer; the gear height adjustment motor 4 is vertically fixed on the bottom of the support 3, the motor shaft of the gear height adjustment motor 4 faces upwards, the leading screw 5 is vertically arranged, and the bottom of the leading screw 5 The end is coaxially connected with the motor shaft of the gear height adjustment motor 4 through a coupling; the slider guide column 7 adopts a parallel double column structure, and the slider guide column 7 is vertically fixed on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com