Pipeline internal detection system

A detection system and pipeline technology, which is applied to pipeline systems, special pipes, pipe components, etc., can solve the problems of slow detection response, inability to realize complex pipeline topology detection, leakage location and early warning of pipe wall corrosion, etc., to achieve high sensitivity, The effect of low self-noise and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

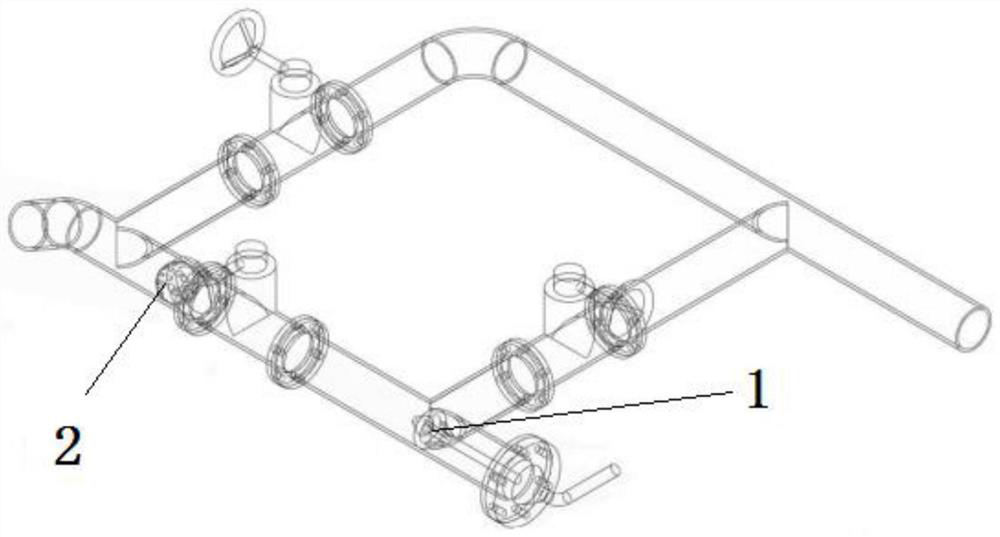

[0034] like figure 1 As shown, an in-pipeline detection system includes a transceiver system 1 and a detector 2. The transceiver system 1 is set at the position of the metal hose at the inlet and outlet of the oil depot tank. The detector 2 is a spherical detector 2, which is put into and recovered through the transceiver system 1 .

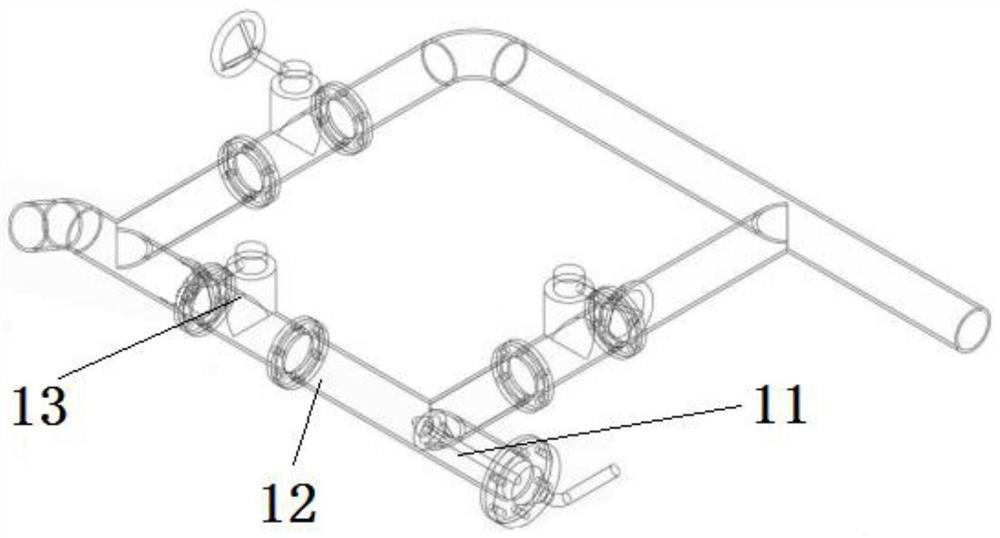

[0035] like figure 2 As shown, the transceiver system 1 includes a transceiver tube 11, a main pipe 12, and a third valve 13. The main pipe 12 is a metal hose pipeline for the inlet and outlet of the tank body of the oil depot. The transmitting and receiving spherical cylinder 11 transmits and receives; the ratio of the diameter of the detector 2 to the pipe diameter is 0.7-0.8:1. The third valve 13 is arranged between the interface position of the first branch pipeline 111 and the interface position of the second branch pipeline 112 in the main pipeline 12 .

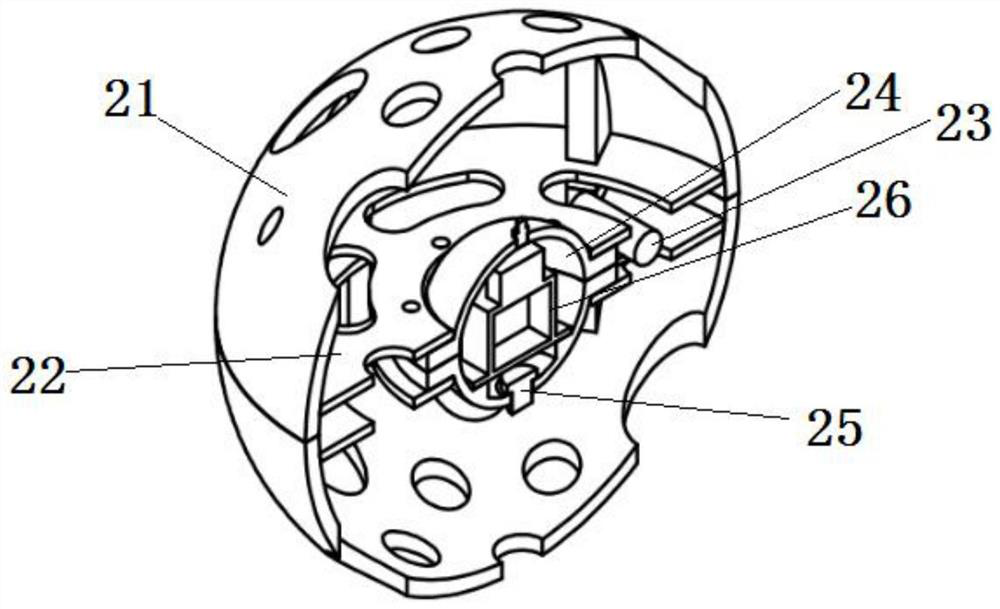

[0036] like image 3As shown, the detector 2 includes a shell 21, a support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com