Annular workpiece size measurement and defect detection method and device

A defect detection and ring-shaped workpiece technology, which is applied in the field of workpiece manufacturing and processing, can solve problems such as the inability to apply automated production lines, low detection speed of ring-shaped workpieces, and inability to accurately identify circles, etc., achieving repeatability advantages, strong stability, good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

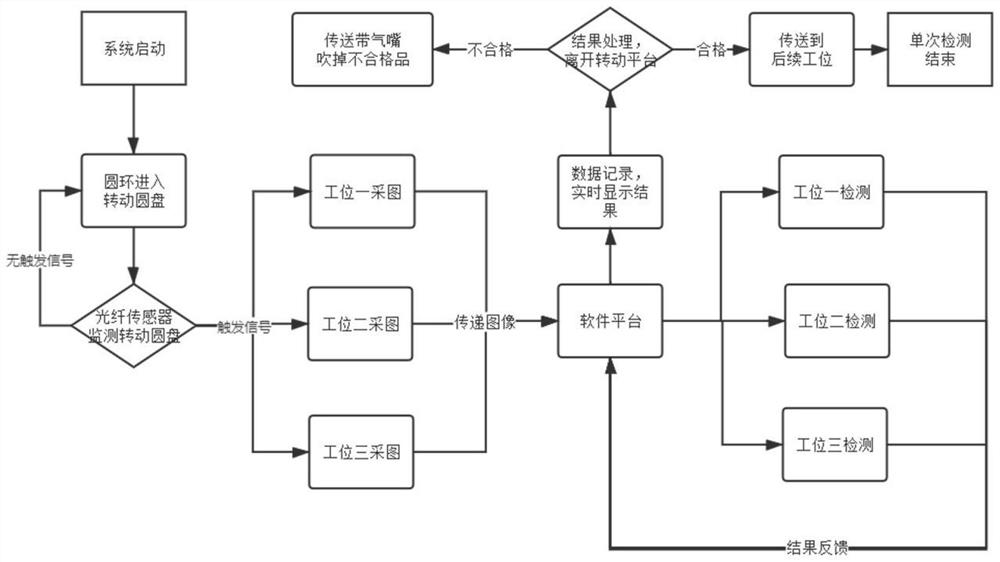

[0041] The invention discloses a method and device for rapid size measurement and defect detection of a ring-shaped workpiece. figure 1 It is a device detection flowchart of the present invention, as shown in the figure:

[0042] Step 1: After the system is started, the circular workpiece enters the rotating disc;

[0043] Step 2: The optical fiber sensor (1) monitors the rotating disc, and a trigger signal is generated when a workpiece passes through;

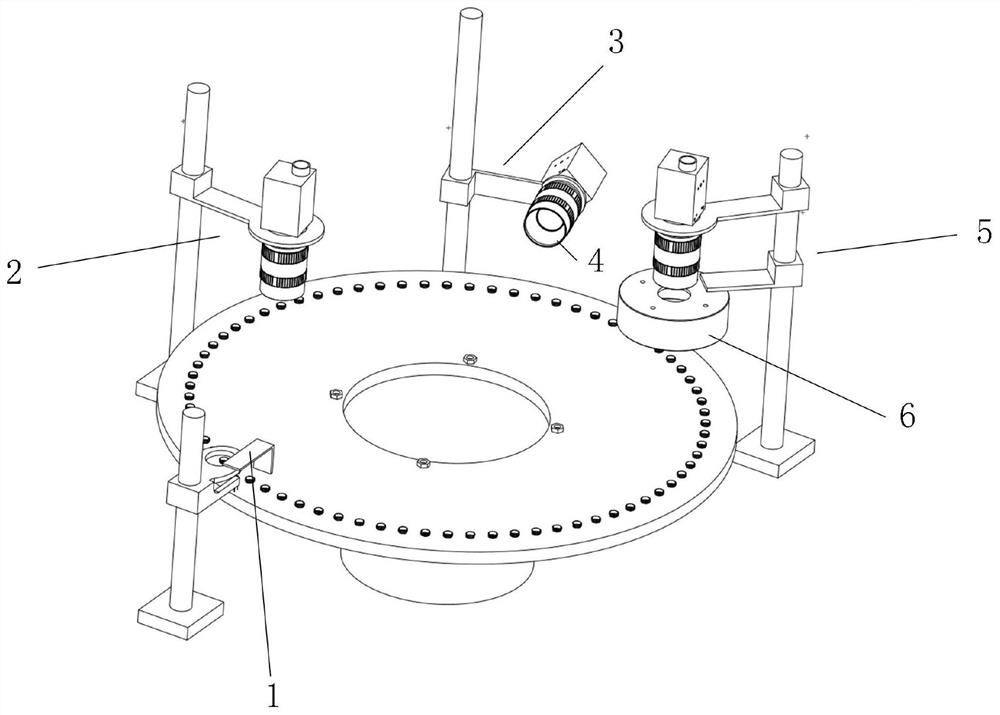

[0044] Step 3: The trigger signal is sent to the three imaging stations respectively, figure 2 It is a schematic diagram of the station layout device of the present invention, and each station device is shown as figure 2 shown.

[0045] Step 4: After the imaging station obtains the image, the original image is sent to the software platform, and the software platform uses different algorithm detection modules for detection according to the images of different stations. Its main detection principle is:

[0046] 1) Station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com