Method and system for supplying materials to mortar station

A material feeding and mortar technology, applied in the field of mortar station batching, can solve the problems that affect the production and use of feeding materials, prone to errors, and feeding errors, etc., to improve the accuracy of measurement, avoid feeding errors, and accurately feed materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

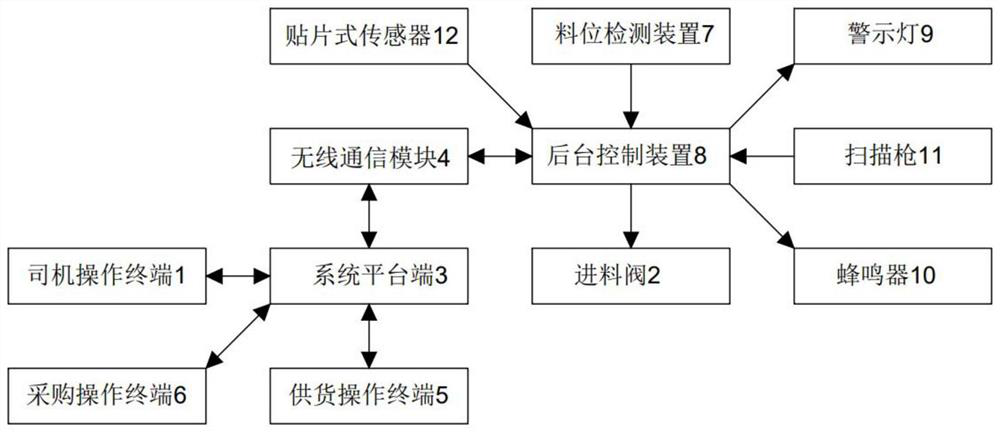

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

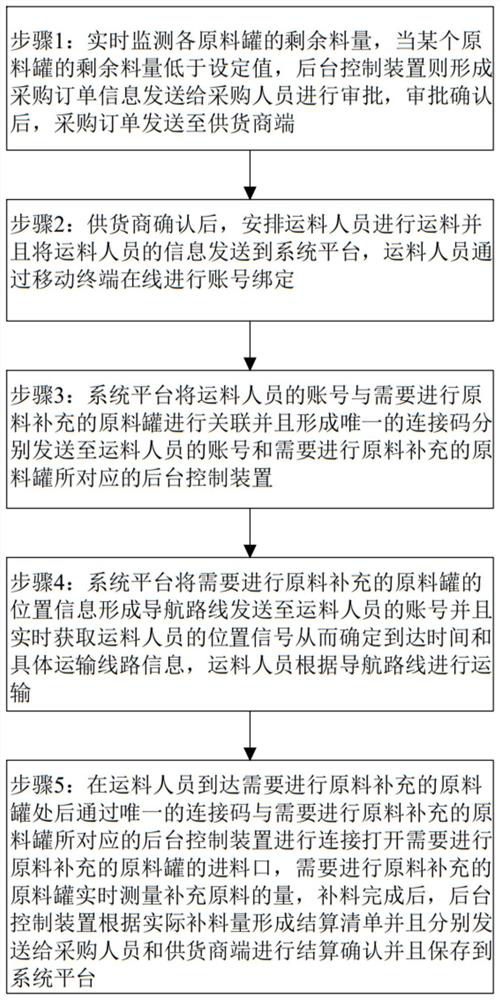

[0025] Such as figure 1 Shown, the present invention provides a kind of method of feeding material to mortar station, comprises following processing step,

[0026] Step 1: Monitor the remaining material volume of each raw material tank in real time. When the remaining material volume of a certain raw material tank is lower than the set value, the background control device 8 will form a purchase order information and send it to the purchaser for approval. After the approval is confirmed, the purchase order sent to the supplier;

[0027] Step 2: After the supplier confirms, arrange the delivery personnel to carry out the delivery and send the information of the delivery personnel to the system platform, and the delivery personnel will bind t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com