Solid-state reflective surface acoustic wave resonator and preparation method thereof

A surface acoustic wave and reflection-type technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of difficult to achieve wide-band filtering, poor RF performance of resonators, and large influence of resonance frequency, achieving excellent performance and solving RF performance changes. Poor, high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the solid-state reflective surface acoustic wave resonator of this embodiment includes the following steps:

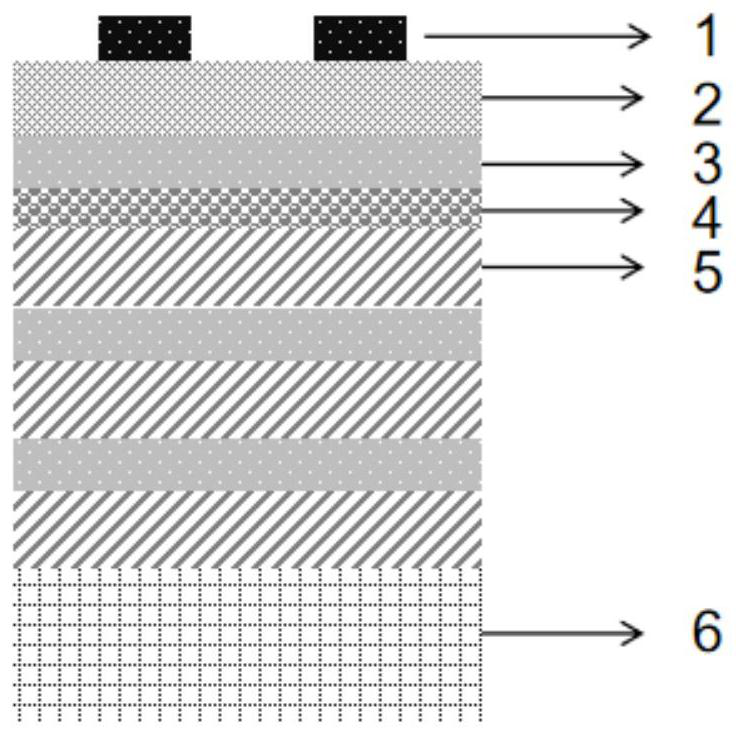

[0028] The reflective layer of this embodiment is a 3-cycle laminated structure in which one layer of low acoustic impedance reflection layer is laminated on one layer of high acoustic impedance reflection layer. The porous structure layer is one layer and is arranged on the top (on the side of the upper electrode. In a reflection layer loop for the above), such as figure 1 structure shown.

[0029] Step 1. First grow a low acoustic impedance reflective layer under the injection surface of the piezoelectric material, and then set a layer of porous structure under the low acoustic impedance reflective layer; the setting method is an ion etching method.

[0030] Then grow a high acoustic impedance reflective layer on the porous structure layer; then continue to grow the rest of the reflective layer cycles, and finally bond the substrate ...

Embodiment 2

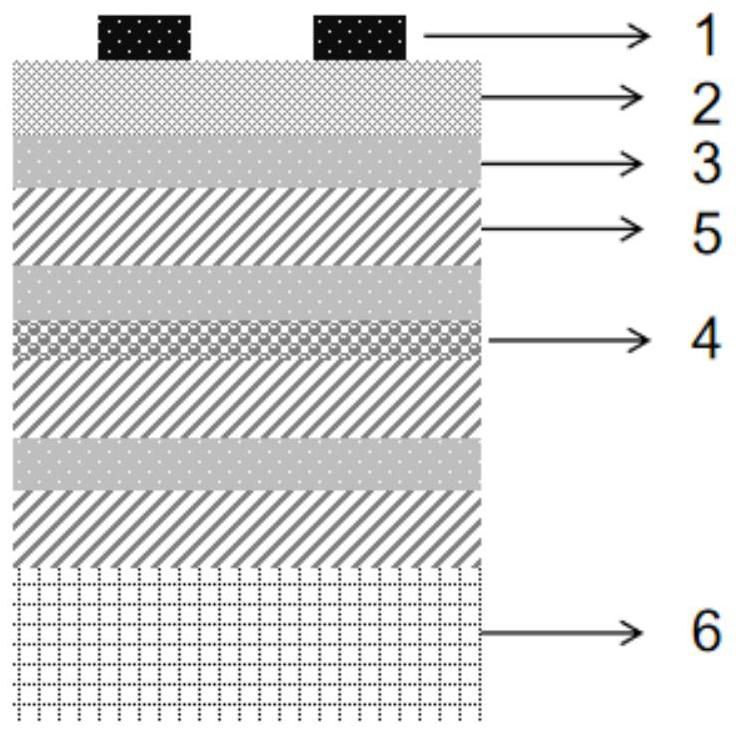

[0036] The preparation method of the solid-state reflective surface acoustic wave resonator of this embodiment is the same as that of Embodiment 1: the difference is that the porous structure layer is one layer, which is arranged in the middle reflective layer circulation, such as figure 2 structure shown.

Embodiment 3

[0038] The structure and preparation method of the novel solid-state reflective surface acoustic wave resonator of this embodiment include the following steps:

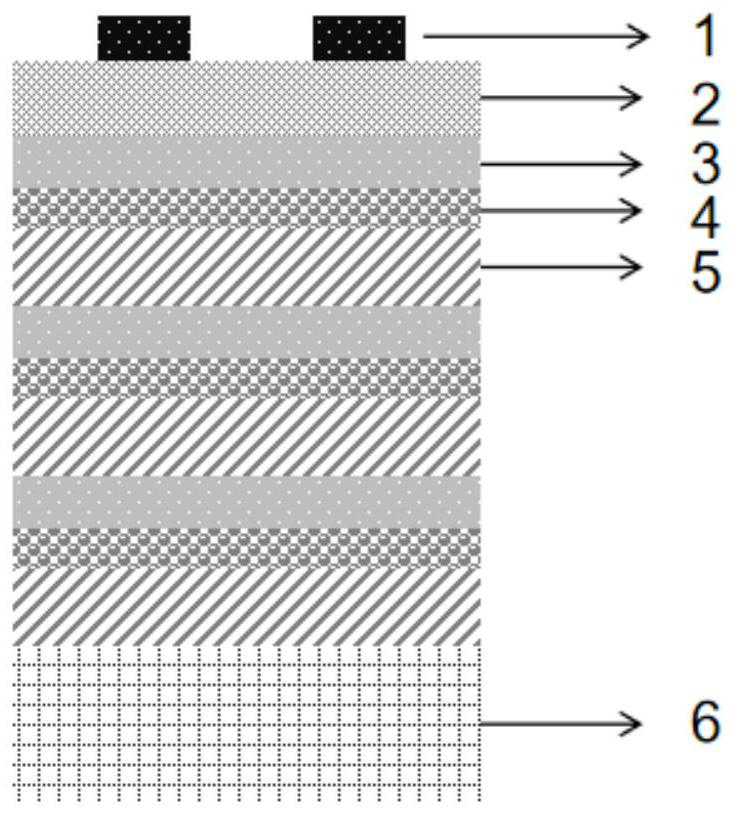

[0039] The reflective layer of this embodiment is a 3-cycle laminated structure in which one layer of low acoustic impedance reflection layer is laminated on one layer of high acoustic impedance reflection layer, and the porous structure layer is 3 layers, which are arranged in each reflection layer cycle, such as image 3 structure shown.

[0040] Step 1, first grow a layer of low acoustic impedance reflective layer under the injection surface of the piezoelectric material, then set a layer of porous structure layer under the low acoustic impedance reflective layer, and then grow a high acoustic impedance reflective layer under the porous structure layer;

[0041] Then, according to the low acoustic impedance reflection layer, the porous structure layer and the high acoustic impedance reflection layer as a cycle stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com