Separator composition, separator, and manufacturing method and use thereof

A composition and separator technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, battery pack components, etc., can solve the problems of unusable heat resistance and low productivity, and achieve increased output and improved photoelectric conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

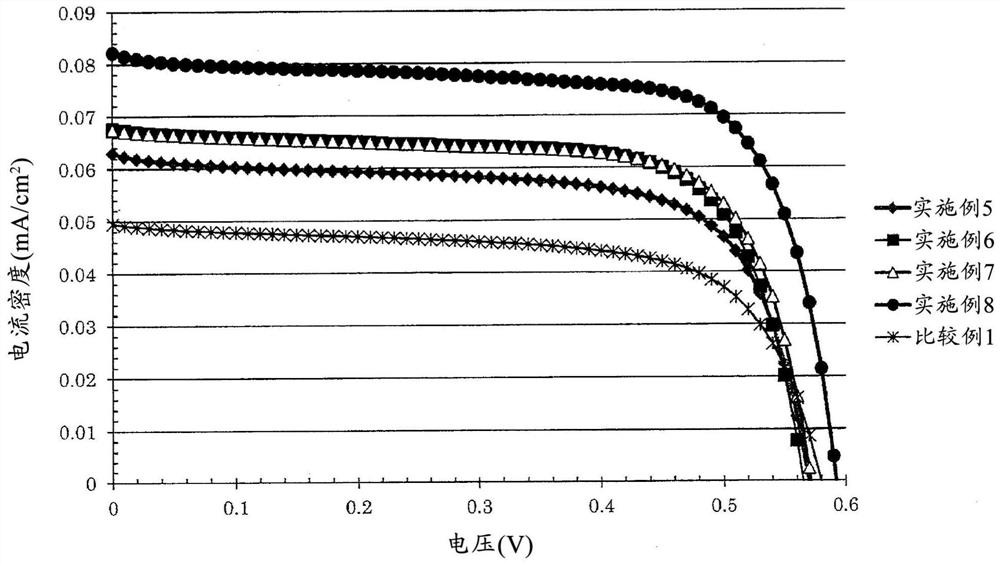

[0150] A 20% by weight Nafion dispersion was neutralized with an aqueous lithium hydroxide solution obtained by dissolving lithium hydroxide monohydrate in ion-exchanged water, and a 5% by weight Nafion dispersion was prepared using ion-exchanged water. 1.8 parts by weight of titanium oxide particles A and 2 parts by weight of isopropanol were added to 6 parts by weight of the 5% by weight Nafion dispersion, followed by dispersion treatment with an ultrasonic homogenizer to obtain a separator ink.

Embodiment 2

[0152] A separator ink was obtained in the same manner as in Example 1 except that 1.8 parts by weight of silica nanoparticles was used instead of 1.8 parts by weight of titanium oxide particles A in Example 1.

Embodiment 3

[0154] A separator ink was obtained in the same manner as in Example 1 except that 1.8 parts by weight of alumina-coated titanium oxide particles was used instead of 1.8 parts by weight of titanium oxide particles A in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com