Floating type photobioreactor system

A photobioreactor, floating technology, applied in the field of microbial breeding, can solve the problems of reducing breeding efficiency, increasing breeding cost, increasing pollution probability, etc., and achieving the effect of simplifying cumbersome process, reducing breeding cost, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

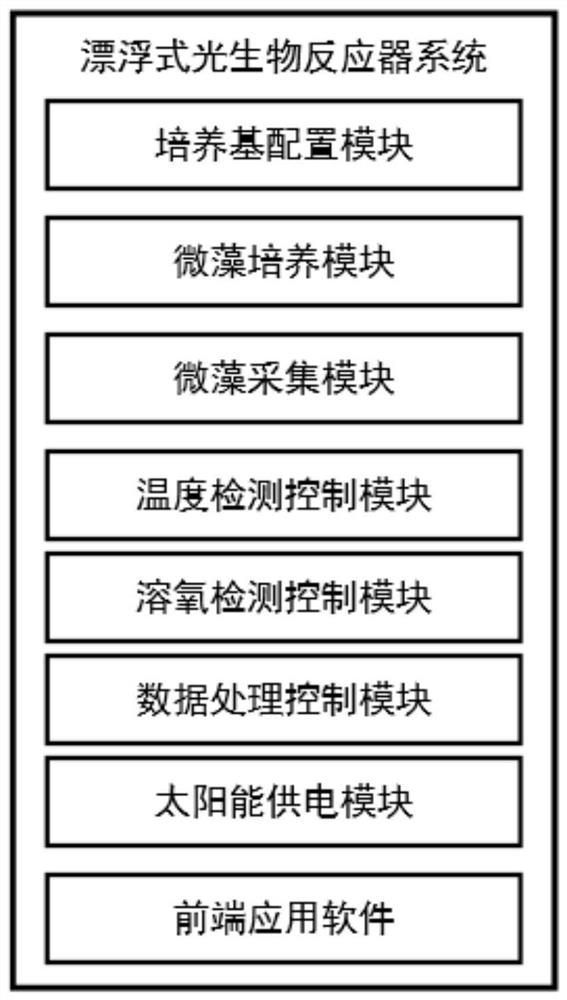

[0038] The invention provides a floating photobioreactor system, which mainly includes a medium preparation module, a microalgae cultivation module, an algae liquid collection module, a temperature detection control module, a dissolved oxygen detection control module, a data Processing control module, solar power supply module, front-end application software.

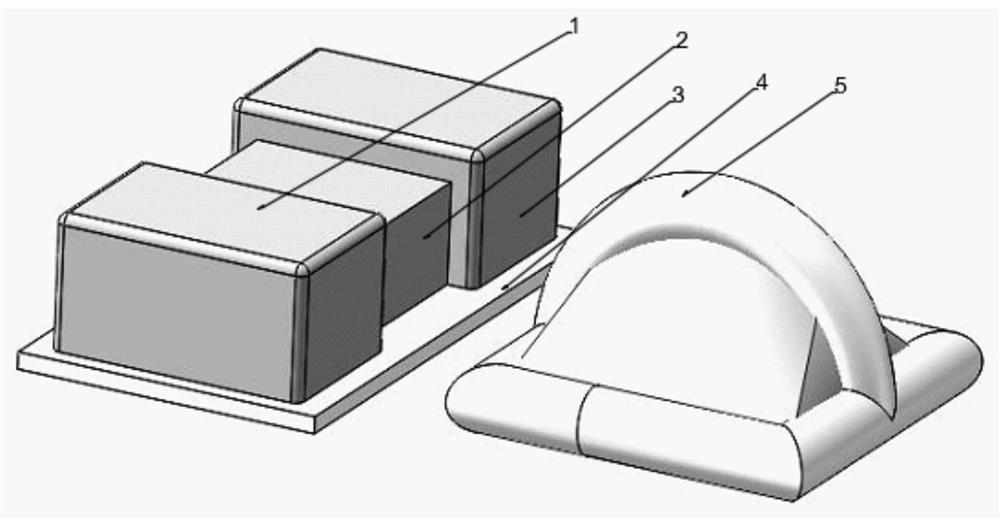

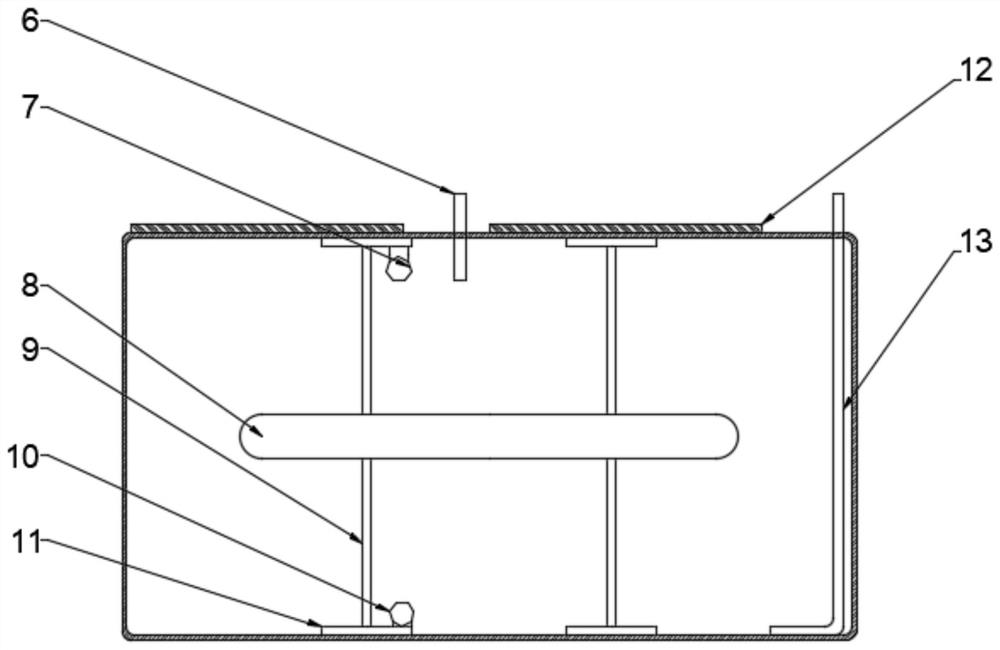

[0039] Dimensions of the main components in the floating photobioreactor system:

[0040] Among them, the size of the water treatment bin and the algae liquid storage bin are both 81*38*45 cm (length, width and height), the size of the storage box is 660*486*410 mm (length, width and height), and the volume of the hard plastic plate 140*90*1 cm, the culture volume of the floating photobioreactor is 75L, the size of the solar panel is 30*30*0.4 cm (length*width*height), the inner diameter of the nylon ventilation tube is 7.5 cm, the steel wire The inner diameter of the hose is 1.0 cm, the length of the cord is 6 meters,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com