Ni-Cu-Ti/CNTs porous composite material and preparation method thereof

A porous composite material, ni-cu-ti technology, applied in electrode coatings, energy input, electrolysis components, etc., can solve the problems of easy loss of hydrogen evolution activity, power-off gap, etc., to achieve rich porosity, extended service life, mechanical Excellent performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

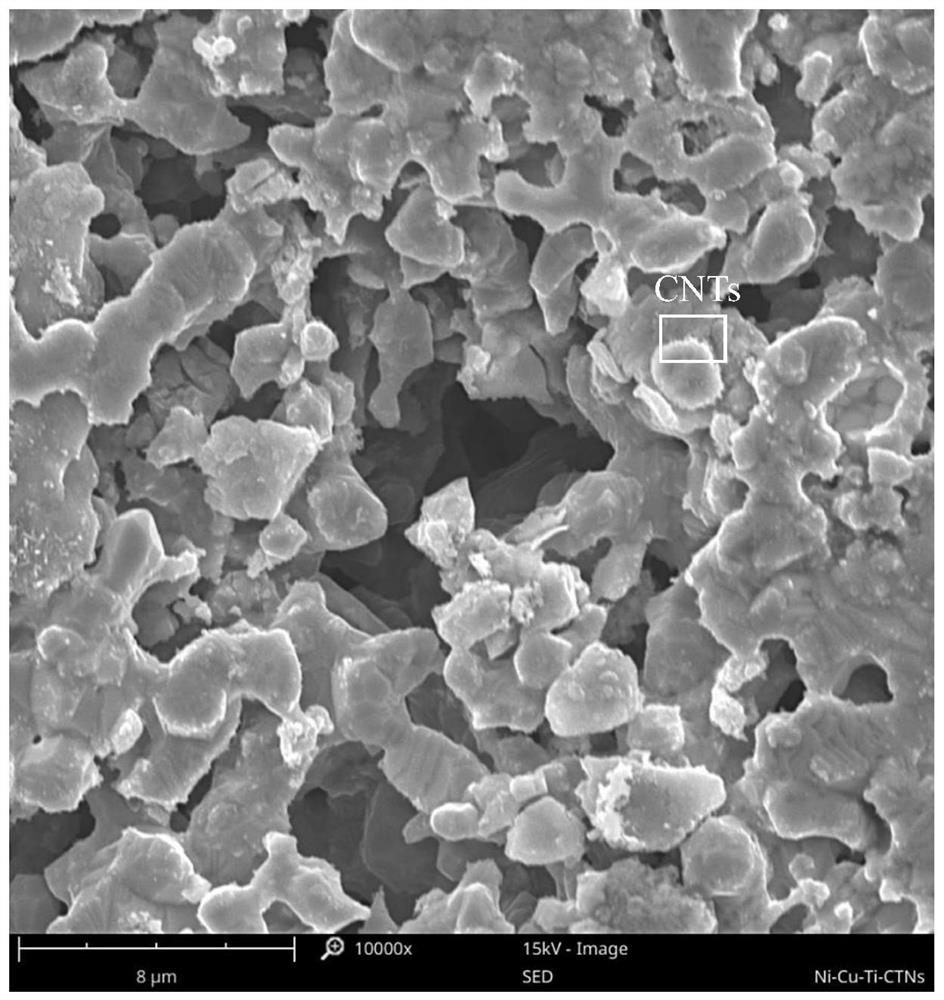

[0026] Three high-purity powders of Ni, Cu, Ti, and CNTs were weighed according to a certain mass ratio, wherein the content of Ni powder was 55%wt, and the particle size of the powder was 5μm; the content of Cu powder was 35%wt, and the particle size of the powder was 5μm; The powder content is 10%wt, the powder particle size is 5μm, the CNTs content is 0.3%wt, and it is a multi-walled carbon nanotube with a length of 1μm. Add the weighed CNTs into deionized water at a ratio of 0.1 g / L, and add 68% sodium dodecylbenzenesulfonate, 150% Tween-20, and 150% poly For vinylpyrrolidone, place the mixed solution in an ultrasonic cleaner for ultrasonic dispersion for 30 minutes. Add the weighed Ni, Cu, and Ti powders after the ultrasonication is completed, and place them on a magnetic stirrer to stir until the solution is separated into layers. After the stirring is completed, perform vacuum filtration, place the separated powder in a vacuum drying oven at 75°C and dry for 5 hours, p...

Embodiment 2

[0030] Weigh three high-purity powders of Ni, Cu, Ti, and carbon nanotubes according to a certain mass ratio, wherein the content of Ni powder is 56%wt, and the particle size of the powder is 4μm; the content of Cu powder is 33%wt, and the particle size of the powder is 4μm ; The content of Ti powder is 11%wt, the particle size of the powder is 4μm, the content of CNTs is 0.4%wt, and it is a multi-walled carbon nanotube with a length of 2μm. Add the weighed CNTs into deionized water at a ratio of 0.1 g / L, and add 68% sodium dodecylbenzenesulfonate, 150% Tween-20, and 150% poly For vinylpyrrolidone, place the mixed solution in an ultrasonic cleaner for ultrasonic dispersion treatment for 30 minutes. Add the weighed Ni, Cu, and Ti powders after the ultrasonication is completed, and place them on a magnetic stirrer to stir until the solution is separated into layers. After the stirring is completed, perform vacuum filtration, place the separated powder in a vacuum drying oven at...

Embodiment 3

[0033] Three high-purity powders of Ni, Cu, Ti, and CNTs were weighed according to a certain mass ratio, wherein the content of Ni powder was 59%wt, and the particle size of the powder was 3μm; the content of Cu powder was 33%wt, and the particle size of the powder was 3μm; The powder content is 8%wt, the powder particle size is 3 μm, the CNTs content is 0.5%, and it is a multi-walled carbon nanotube with a length of 0.5 μm. Add the weighed CNTs into deionized water at a ratio of 0.1g / L, and add 68% sodium dodecylbenzenesulfonate, 150% Tween-20, and 150% polyethylene For pyrrolidone, place the mixed solution in an ultrasonic cleaner for ultrasonic dispersion treatment for 30 minutes. Add the weighed Ni, Cu and Ti powders after the ultrasonication is completed, and place them on a magnetic stirrer to stir until the solution is separated into layers. After the stirring is completed, perform vacuum filtration, place the separated powder in a vacuum drying oven for 5 hours at 75°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com