Polyamide large bio-fiber containing cocoa active ingredients and preparation method of polyamide large bio-fiber

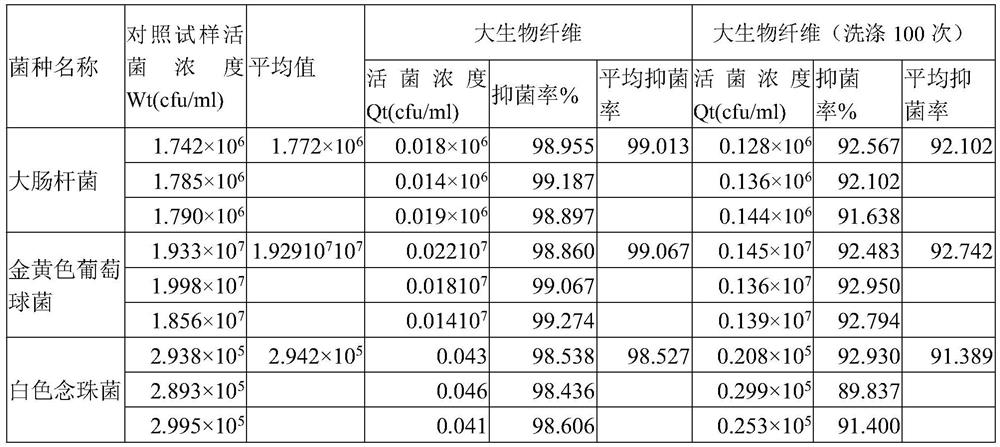

A technology of biological fibers and active ingredients, which is applied in the field of preparation of nylon large biological fibers, can solve the problems of nylon fabric's anti-oxidation and antibacterial properties, yellowing level cannot be reached, and low bonding stability, etc., and achieve good anti-oxidation Virus effect, good antibacterial effect, and good immobilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Such as figure 1 Shown, a kind of preparation method of the nylon big biological fiber containing cocoa active ingredient comprises the steps:

[0042] Extraction of S1 cocoa epicatechin;

[0043] Modification of S2 cocoa epicatechin;

[0044] Preparation of S3 porous nano silicon dioxide particles;

[0045] Modification of S4 porous nano-silica particles;

[0046] Preparation of S5 molecular nest;

[0047] Modification of S6 molecular nest;

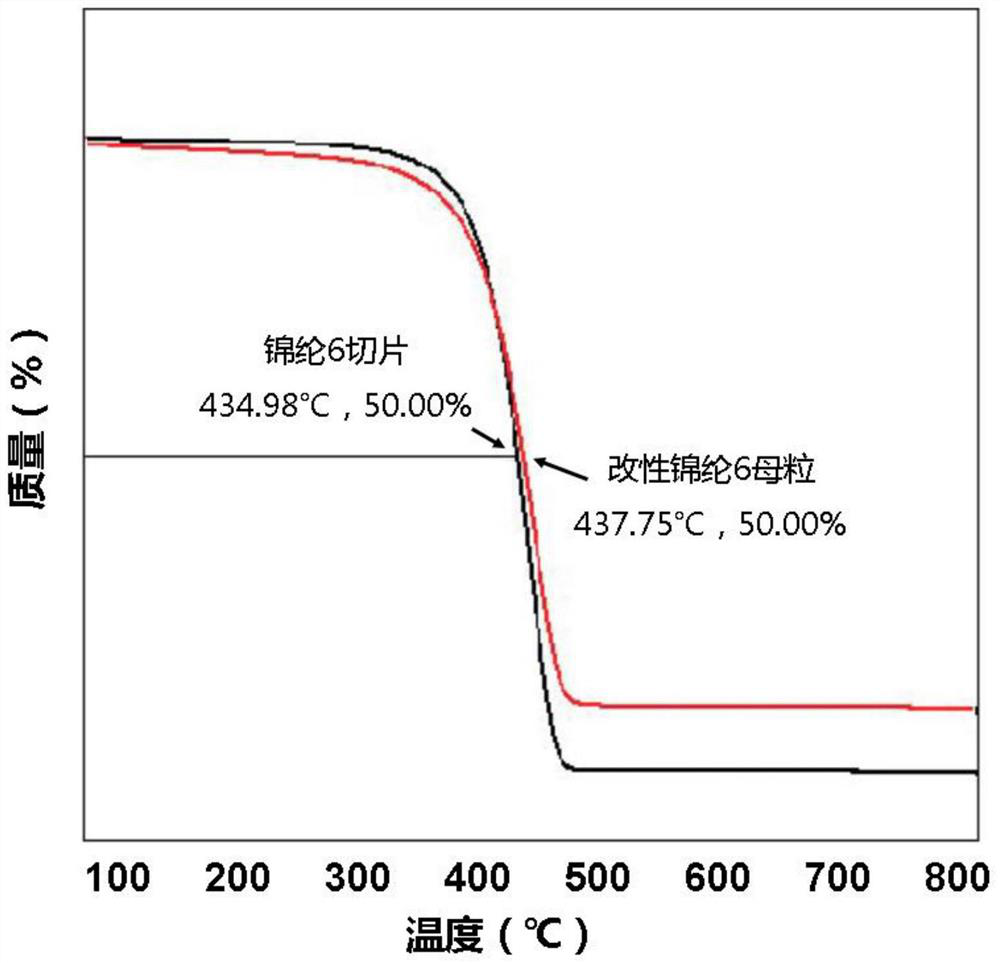

[0048] Preparation of S7 masterbatch containing molecular nests;

[0049] S8 Preparation of nylon macrobiological fibers containing cocoa active ingredients.

[0050] The step S1 is prepared by alcohol extraction plus ultrasonic extraction as follows:

[0051] Each time, take 100g of pre-crushed cocoa beans and dissolve them in 40-60% ethanol according to the ratio of material to liquid (w / v) 1:15-1:25, and place them in an ultrasonic cleaner (frequency 45KHz). Power 200-250W, temperature 20-40 ℃ for 10-20min, the extract wa...

specific Embodiment 1

[0070] A preparation method of nylon macrobiological fiber containing cocoa active ingredients, comprising the steps of:

[0071] Extraction of S1 cocoa epicatechin;

[0072] Modification of S2 cocoa epicatechin;

[0073] Preparation of S3 porous nano silicon dioxide particles;

[0074] Modification of S4 porous nano-silica particles;

[0075] Preparation of S5 molecular nest;

[0076] Modification of S6 molecular nest;

[0077] Preparation of S7 masterbatch containing molecular nests;

[0078] S8 Preparation of nylon macrobiological fibers containing cocoa active ingredients.

[0079] Step S1, the preparation method is as follows by using alcohol extraction plus ultrasonic extraction method:

[0080] Each time, take 100g of pre-crushed cocoa beans and dissolve them in 40% ethanol according to the ratio of material to liquid (w / v) 1:15, and place them in an ultrasonic cleaner (frequency 45KHz). After processing for 10 min, the extract was centrifuged at 4000 r / min for 5...

specific Embodiment 2

[0099] A preparation method of nylon macrobiological fiber containing cocoa active ingredients, comprising the steps of:

[0100] Extraction of S1 cocoa epicatechin;

[0101]Modification of S2 cocoa epicatechin;

[0102] Preparation of S3 porous nano silicon dioxide particles;

[0103] Modification of S4 porous nano-silica particles;

[0104] Preparation of S5 molecular nest;

[0105] Modification of S6 molecular nest;

[0106] Preparation of S7 masterbatch containing molecular nests;

[0107] S8 Preparation of nylon macrobiological fibers containing cocoa active ingredients.

[0108] Step S1, the preparation method is as follows by using alcohol extraction plus ultrasonic extraction method:

[0109] Each time, take 100g of pre-crushed cocoa beans and dissolve them in 50% ethanol according to the ratio of material to liquid (w / v) 1:25, and place them in an ultrasonic cleaner (frequency 45KHz). After processing for 20 minutes, the extract was centrifuged at 4000 r / min fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com