Far-infrared ceramic powder as well as preparation method and application thereof

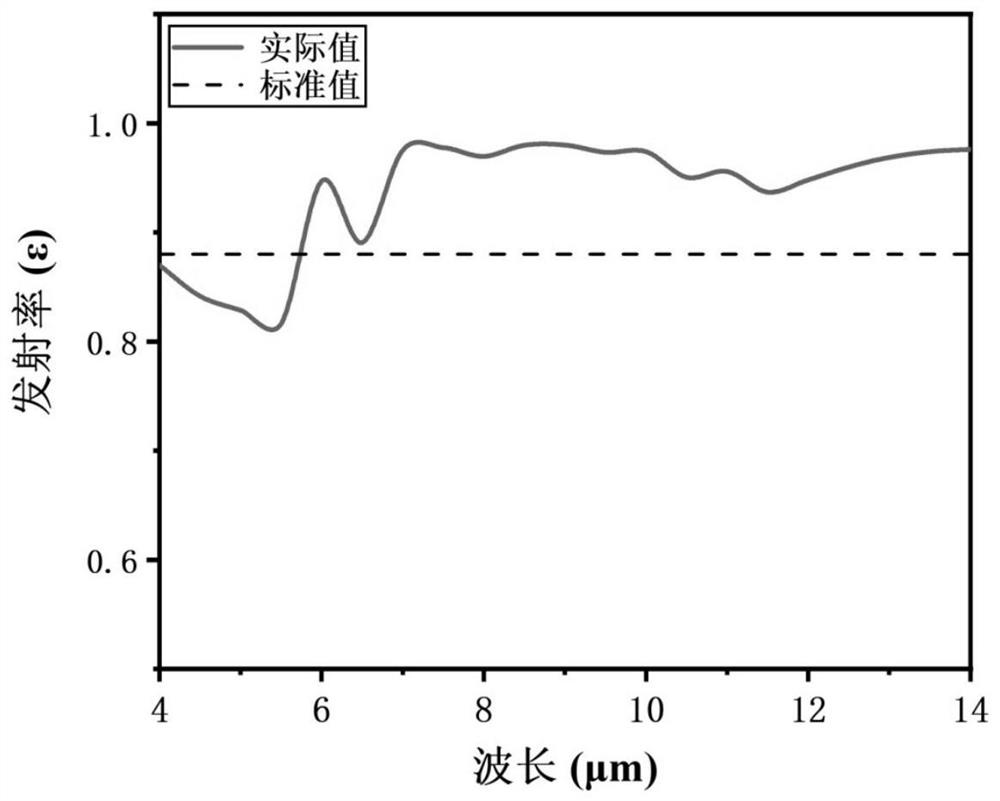

A far-infrared ceramic powder and far-infrared technology are applied in textiles and papermaking, fiber types, fiber treatment, etc., which can solve the problems of complex fabric structure, narrow application area, and poor effect, and achieve simple preparation methods, low cost, Good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment: the composition of the fabric is red 100% cotton; the far-infrared ceramic powder includes 65 parts of zirconia, 5 parts of lanthanum oxide and 10 parts of yttrium oxide; the particle size of the far-infrared ceramic powder is 0.1 μm~0.2 μm.

[0040] The fabric is impregnated with 55wt% phosphoric acid, the impregnation time is 30min, and the impregnation temperature is 20°C. After impregnation, the cotton fiber swells to form fine pores, so that the far-infrared ceramic powder particles can enter the interior of the fiber and increase the Larger contact area with fibers improves the adsorption rate of fabrics to far-infrared ceramic powder.

[0041] The far-infrared ceramic powder is coated on the fabric by padding, and it is fixed after pre-baking at 80°C for 1 minute and baking at 160°C for 2 minutes to obtain a fabric with far-infrared function.

[0042] During the padding treatment, the pretreated fabric is padded in the padding solution. In t...

Embodiment 2

[0047] In this embodiment: the composition of the fabric is 100% red polyester fiber; the far-infrared ceramic powder includes 65 parts of zirconia, 5 parts of lanthanum oxide and 10 parts of yttrium oxide; the particle size of the far-infrared ceramic powder is 0.1 μm ~0.2 μm.

[0048] The fabric is impregnated with 55wt% phosphoric acid, the impregnation time is 30min, and the impregnation temperature is 20°C. After impregnation, the surface of the polyester fiber is etched to form fine pores to facilitate the entry of far-infrared ceramic powder particles into the fiber. Inside, the contact area with the fiber is increased, and the adsorption rate of the fabric to the far-infrared ceramic powder is improved.

[0049] The far-infrared ceramic powder is formed on the fabric by padding, and it is fixed after pre-baking at 90°C for 1 minute and baking at 180°C for 3 minutes to obtain a fabric with far-infrared function.

[0050] During the padding treatment, the pretreated fab...

Embodiment 3

[0055] In this embodiment: the composition of the fabric is 100% viscose fiber; the far-infrared ceramic powder comprises 65 parts of zirconia, 10 parts of lanthanum oxide and 10 parts of yttrium oxide; the particle size of the far-infrared ceramic powder is 0.1 μm ~0.2 μm.

[0056] The fabric is impregnated with 55wt% phosphoric acid, the impregnation time is 30min, and the impregnation temperature is 20°C. After impregnation, the surface of the viscose fiber is etched to form fine gaps to facilitate the entry of far-infrared ceramic powder particles. Inside the fiber, the contact area with the fiber is increased, and the adsorption rate of the fabric to the far-infrared ceramic powder is improved.

[0057] The far-infrared ceramic powder is formed on the fabric by padding method, and it is fixed after pre-baking at 90°C for 1 minute and baking at 180°C for 3 minutes to obtain a fabric with far-infrared function.

[0058] During the padding treatment, the pretreated fabric i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com