<99>Mo subcritical production device and method based on Th-U self-sustaining cycle

A production device and subcritical technology, applied in the field of 99Mo subcritical production device based on Th-U self-sustaining cycle, can solve the problems of high cost, low output, complicated production process, etc., and achieve low cost, efficient and stable production, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

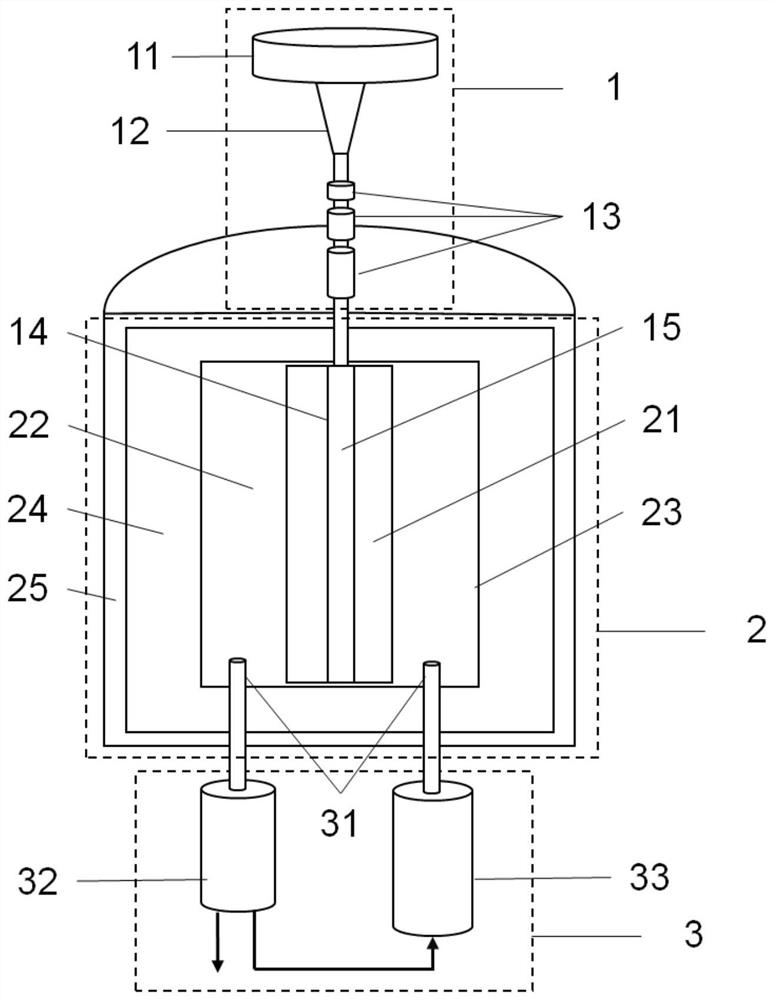

[0038] like Figure 1~2 As shown, a Th-U self-sustaining cycle-based 99 Mo subcritical production device, including accelerator system 1, 99 Mo production system 2 and separation and purification unit 3.

[0039] The accelerator system 1 is used for accelerating, transporting ion beams, and generating neutrons.

[0040] 99 Mo production system 2 is connected with accelerator system S1 for introducing neutron flow, through 233 U(n,f) 99 Mo reaction production 99 Mo, 99 Mo fission yield is about 5.13%; meanwhile, 232 Th captures neutrons and undergoes a series of decay multiplication to obtain 233 U, newly generated 233 U fully replenishes the consumed 233 U fuel, to achieve Th-U self-sustaining cycle.

[0041] Separation and purification unit 3 and 99 Mo production system 2 is connected for drawing out the solution after the reaction and carrying out 99 The separation and purification of Mo is refluxed after pH adjustment 99 Mo Production System 2.

[0042] Speci...

Embodiment 2

[0047] A kind of based on Th-U self-sustaining cycle of the present embodiment 99 Mo subcritical production method, adopt embodiment 1 device; Described production method comprises the steps:

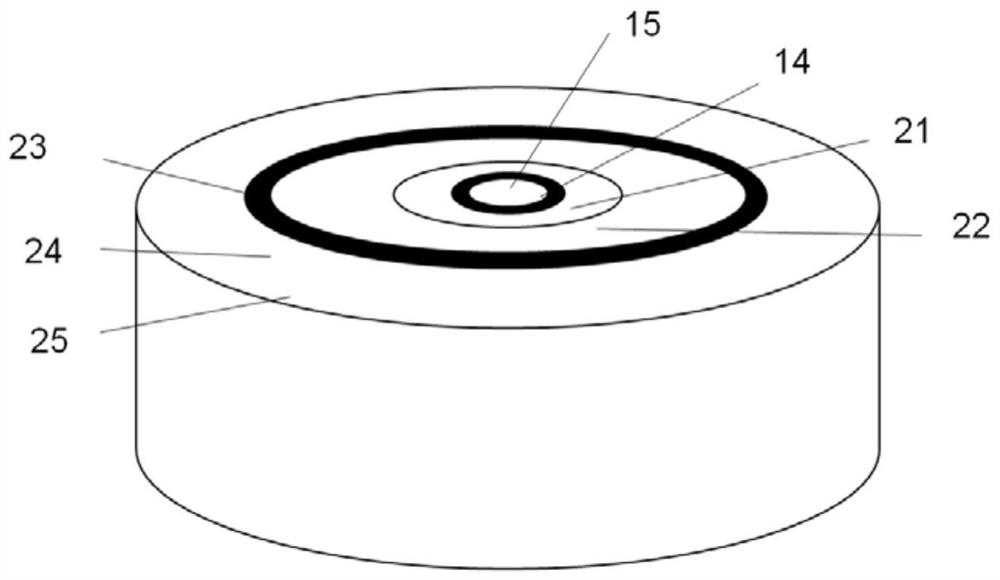

[0048] (1) The ion source 11 is a deuterium ion beam, and the target 15 is a gaseous tritium target in the target chamber 14, which emits 14.1 MeV neutrons through deuterium-tritium fusion reaction. Specifically, the deuterium ion beam collimated by the collimator 12 and accelerated by the accelerator 13 bombards the gaseous target-tritium target, and D-T fusion reaction occurs to emit source neutrons; the size of the gaseous tritium target is ( h=80cm), the target cavity 14 is made of stainless steel with a thickness of 0.2cm.

[0049] (2) Neutrons enter the neutron multiplication layer 21, which is made of beryllium. After neutrons have undergone multiple (n, 2n) reactions, the energy drops to the doubling threshold, and at the same time, part of the neutrons are slowed down to the...

Embodiment 3

[0056] A kind of based on Th-U self-sustaining cycle of the present embodiment 99 Mo subcritical production method, adopt embodiment 1 device; Described production method comprises the steps:

[0057] (1) The ion source 11 is a proton beam with a beam intensity of 100 μA, and the target 13 is a tungsten heavy nuclear target, which emits neutrons through heavy nuclear fission reactions. Specifically, after being collimated by the collimator 12, the proton beam accelerated by the 20MeV linear accelerator 13 followed by the 500MeV fast-cycle synchrotron 13 bombards the solid-state target-tungsten target, and a heavy nuclear fission (p, xn) reaction occurs to emit source neutrons ( Contains 15% fast neutrons and 1% ultrafast neutrons); the dimensions of the solid tungsten target are 5 cm in diameter and 10 cm in height.

[0058] (2) The neutrons generated by the accelerator system 1 enter the neutron multiplication layer 21, which is made of beryllium. After multiple (n, 2n) rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com