Bean curd preparation method for improving elasticity of bean curd based on sour pulp coagulator

A technology of coagulant and tofu, applied in the field of tofu preparation, can solve the problems of toughness to be improved, low production efficiency, inability to adapt to industrial production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

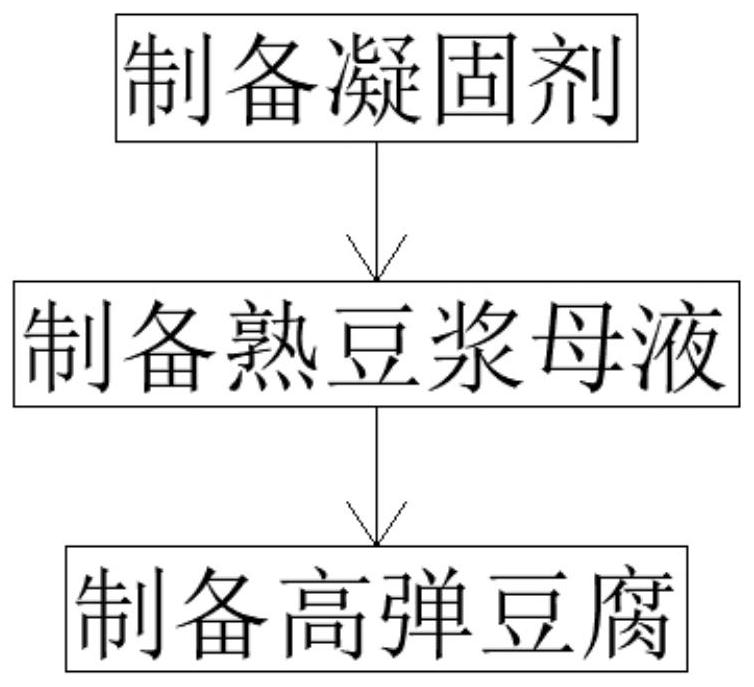

[0025] see Figure 1-4 , in the embodiment of the present invention, a kind of bean curd preparation method to improve bean curd elasticity based on Physalis coagulant, comprises the following steps:

[0026] S1: Preparation of a coagulant: inoculating the fermented bacteria into yellow pulp water for fermentation to prepare a coagulant;

[0027] S2: Prepare cooked soybean milk mother liquor: remove impurities from soybeans, wash, soak, beat, remove slag, and then boil, add carrageenan while stirring to obtain cooked soybean milk mother liquor;

[0028] S3: Preparation of high-elastic tofu: adding a coagulant to the cooked soybean milk mother liquor to obtain high-elastic tofu.

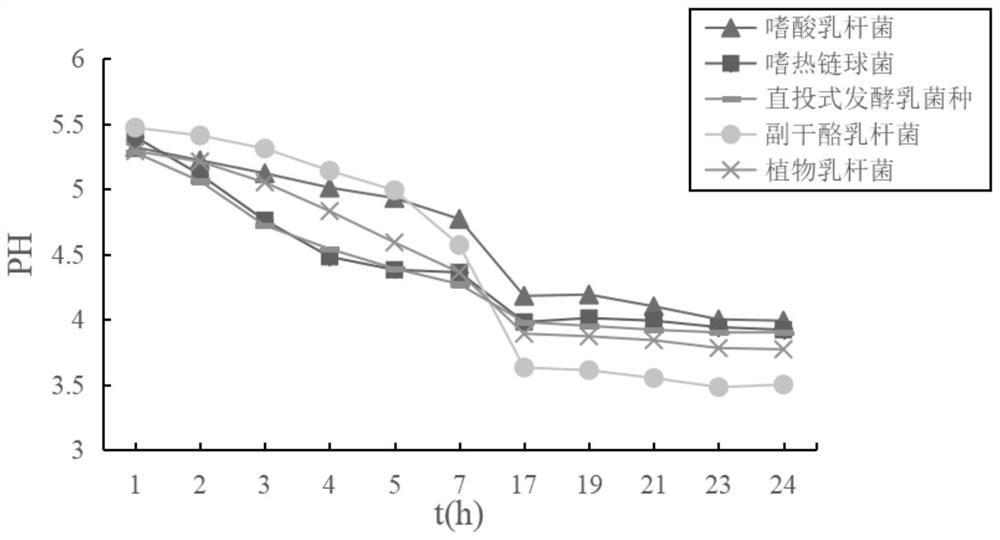

[0029] Preferably, the fermentation strain in the step S1 is one of Lactobacillus paracasei, Lactobacillus acidophilus, Streptococcus thermophilus, Lactobacillus plantarum, Lactobacillus helveticus, Lactobacillus rhamnosus, Lactococcus lactis, Pediococcus lactis species or several.

[0030] Prefera...

Embodiment 2

[0039] see Figure 1-4 , in the embodiment of the present invention, a kind of bean curd preparation method to improve bean curd elasticity based on Physalis coagulant, comprises the following steps:

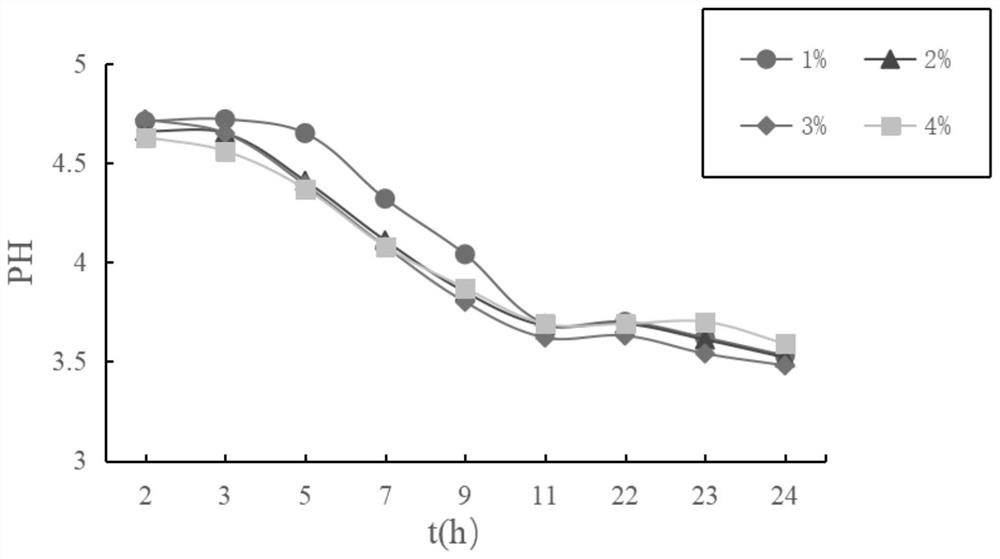

[0040] S1: Preparation of coagulant: Take 250 ml of yellow slurry water and sterilize it in a boiling water bath for 10 minutes, cool it down to about 35 °C and insert the compound strains (Lactobacillus paracasei: Lactobacillus acidophilus: Streptococcus thermophilus=1 :1:1), the inoculum of lactic acid bacteria was 3%. After inoculation, the yellow pulp water was fermented at 37°C for 24 hours to obtain the Physalis Coagulant for later use.

[0041] S2: Preparation of cooked soybean milk mother liquor: remove impurities from soybeans, wash, soak, beat, remove slag, and then boil, and add 2% carrageenan while stirring at not lower than 80°C to obtain cooked soybean milk mother liquor.

[0042] S3: Add the above-prepared physalis coagulant to the cooked soymilk mother liquor a...

Embodiment 3

[0045] see Figure 1-4 , in the embodiment of the present invention, a kind of bean curd preparation method to improve bean curd elasticity based on Physalis coagulant, comprises the following steps:

[0046] S1: Preparation of coagulant: Take 250 ml of yellow slurry water and sterilize it in a boiling water bath for 10 minutes, cool to about 35 °C and insert the compound strains (Lactobacillus paracasei: Lactobacillus acidophilus: Streptococcus thermophilus=1 :1:1), the inoculum of lactic acid bacteria was 3%. After inoculation, the yellow pulp water was fermented at 37°C for 24 hours to obtain the Physalis Coagulant for later use.

[0047] S2: Preparation of cooked soybean milk mother liquor: remove impurities from soybeans, wash, soak, beat, remove slag, and then boil, and add 2% carrageenan while stirring at not lower than 80°C to obtain cooked soybean milk mother liquor.

[0048] S3: Add the prepared physalis coagulant in the ratio of 4% to the mother liquid of cooked s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com