Rotational flow atomization anti-blocking sprayer

A sprayer and anti-blocking technology, applied in the field of atomization, can solve problems such as nozzle blockage, nutrient solution cannot be sprayed on time, uneven spraying, etc., to achieve the effect of full absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

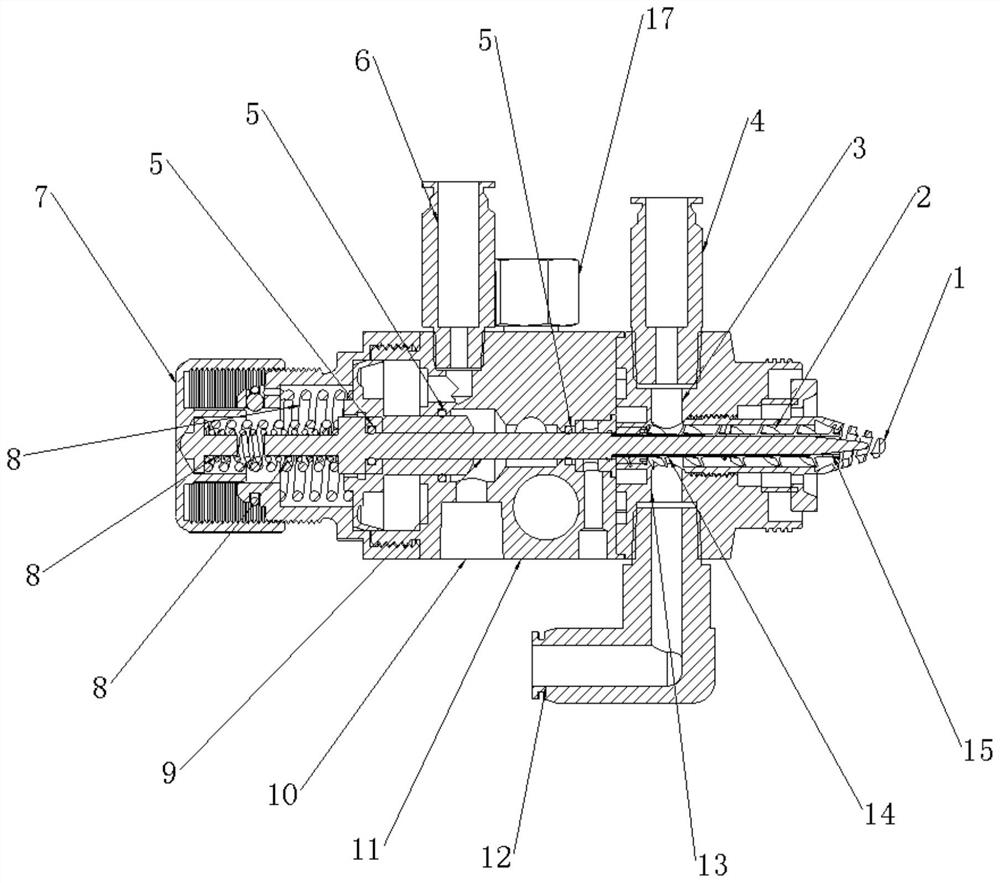

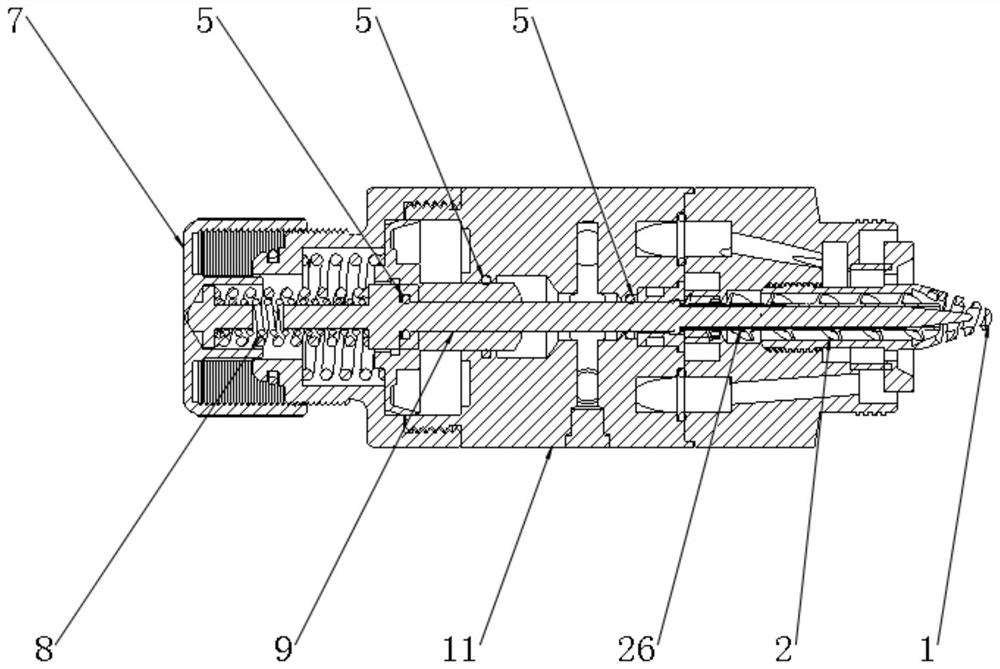

[0032] Embodiment 1 of the present invention provides a cyclone atomization anti-clogging sprayer. The sprayer first uses compressed gas and nutrient solution to collide multiple times in the first atomization chamber to form first atomized droplets, which are generated by the rotation of the spiral connecting rod. The centrifugal force brings the first atomized droplets to the nozzle to collide again to form the second atomized droplets. After two atomization processes, the atomizer of the present invention can obtain smaller and more uniform droplets.

[0033] Such as figure 1 As shown, the swirl atomization anti-clogging sprayer provided by the present invention includes a housing 11, a housing cap 7 and a nozzle 1. The housing 11, the housing cap 7 and the nozzle 1 are provided with an inner cavity, and a spiral is coaxially arranged on the inner cavity. The connecting rod 9, the inner cavity of the present invention and the spiral connecting rod 9 are all arranged in a ci...

Embodiment 2

[0051] Embodiment 2 of the present invention provides a swirling atomization anti-clogging sprayer. The sprayer utilizes the compressed gas injected at high speed and the nutrient solution injected at high speed to collide in the first atomization chamber, and the centrifugal force generated when the spiral connecting rod 9 rotates It will wash away sediments such as mineral elements deposited in the inner cavity of the cylinder and the inner cavity of the nozzle, eliminating the hidden danger of sediment blocking the nozzle.

[0052] Such as figure 1 As shown, the swirl atomization anti-clogging sprayer provided by the present invention includes a housing 11, a housing cap 7 and a nozzle 1. The housing 11, the housing cap 7 and the nozzle 1 are provided with an inner cavity, and a spiral is coaxially arranged on the inner cavity. The connecting rod 9, the inner cavity of the present invention and the screw connecting rod 9 are all arranged in a circular structure, and the cir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap