Efficient automatic metal wire cutting and pressing machine and working method thereof

A metal wire and pressing machine technology, applied in the direction of wire processing, other household appliances, household appliances, etc., can solve the problems of slow cutting speed, inability to effectively ensure the qualified rate of wire threads, etc., to improve the cutting speed and processing. Efficiency and the effect of ensuring accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

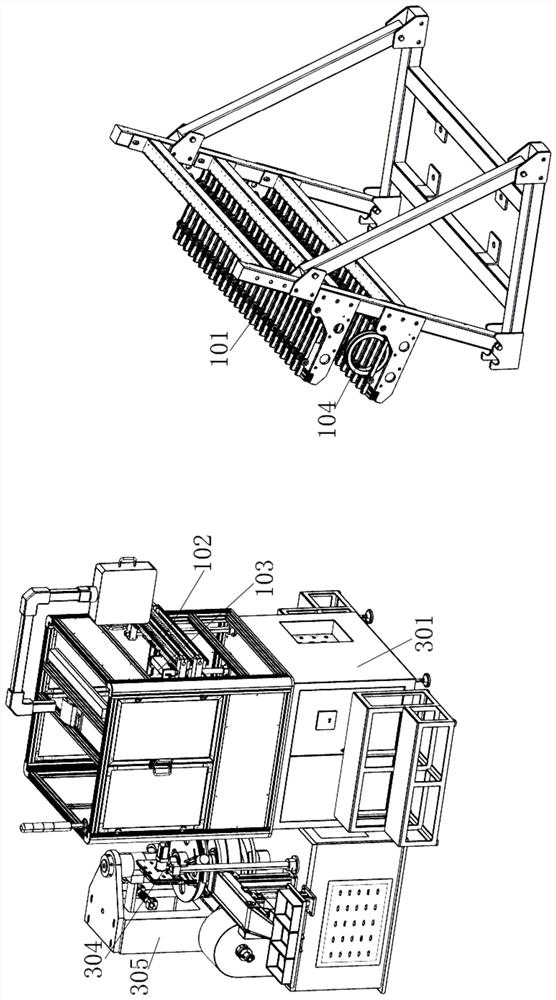

[0047] Such as figure 1 with 14 The high-efficiency wire automatic cutting and pressing machine shown includes a wire reel support frame 101, a wire threading mechanism 102, a wire winding mechanism 103, a cutting machine table 301, a wire cutting mechanism 302, a wire receiving mechanism 303, and a metal ball The pressing mechanism 304 and the metal ball discharging mechanism 305, the wire reel support frame 101 and the metal ball pressing mechanism 304 are located on both sides of the cutting machine table 301 respectively, and the wire reel support frame 101 and the metal ball pressing mechanism 304 are arranged oppositely The wire threading mechanism 102 and the wire winding mechanism 103 are arranged at one end of the cutting machine table 301 close to the wire reel support frame 101, and the wire receiving mechanism 303 is arranged at one end of the cutting machine table 301 close to the metal ball pressing mechanism 304 , the wire cutting mechanism 302 is arranged on t...

Embodiment 2

[0053] Based on the structure of Embodiment 1, such as Figure 15 with 16 The shown wire receiving mechanism 303 includes a wire receiving hopper 201, a wire receiving cylinder 202, a wire receiving clip 203, a wire storage hopper 204 and a fixed mounting plate 205 for receiving materials. The material cylinder 202 and the wire storage hopper 204 are all arranged on the material receiving fixed installation plate 205, and the piston rod of the metal wire material receiving cylinder 202 is connected with one end of the wire material receiving clip 203, and the wire receiving clip 203 The end of 203 away from the metal wire receiving cylinder 202 is inserted into the wire storage hopper 204, and the wire receiving clip 203 can divide the wire storage hopper 204 into upper and lower cavities. The wire receiving hopper 201 The discharge port of the metal wire storage hopper is positioned directly above the feed port of the wire storage hopper 204. Both the wire receiving hopper ...

Embodiment 3

[0065] On the basis of the structure of Embodiment 2, the working method of the high-efficiency metal wire automatic cutting press of the present invention comprises the following steps:

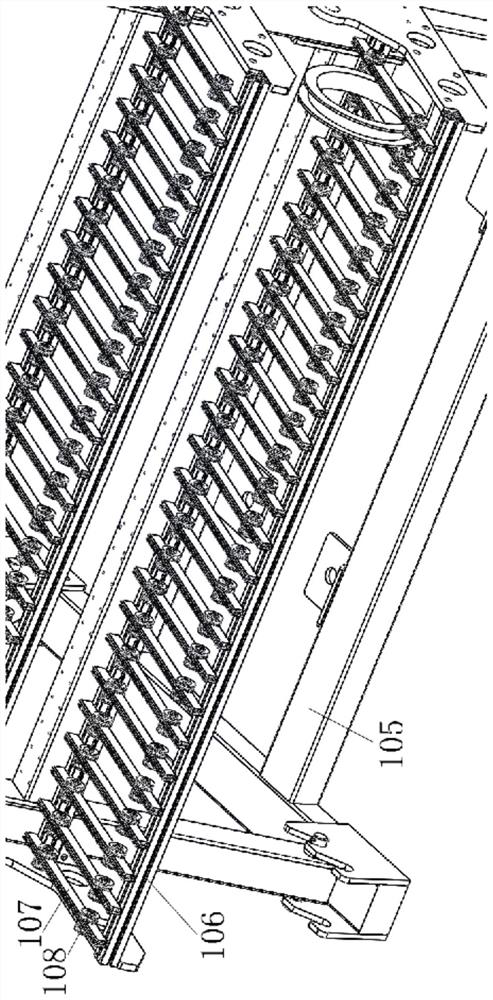

[0066] S1, a group of wire reels 104 are placed on the wire reel support plate 106 one by one, so that the wire reels 104 are placed between the wire guide wheels 108;

[0067] S2, pull the wire of the wire reel 104, so that the wire passes through the threading hole 112 on the threading rod 111 corresponding to the wire reel 104;

[0068] S3, continue to pull the wire, so that the wire passes through the wire hole 114 on the wire rod 113 corresponding to the wire rod 111;

[0069] S4, the metal wire passing through the wire hanging hole 114 is passed through the threading hole 123;

[0070] S5. Continuously repeat the above steps S2~S4, so that the wires on one group of wire reels 104 pass through the wire threading mechanism 102 and the wire winding mechanism 103. Since the distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com