Low-temperature thermal insulation plate of refrigerator car and manufacturing method thereof

A production method and heat insulation board technology, which are applied to chemical instruments and methods, the upper structure of trucks, vehicle parts, etc., can solve the problems of poor low temperature resistance, short insulation boards of refrigerated cars, and easy breakage, etc. Achieve the effects of good temperature insulation effect, excellent low temperature resistance and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

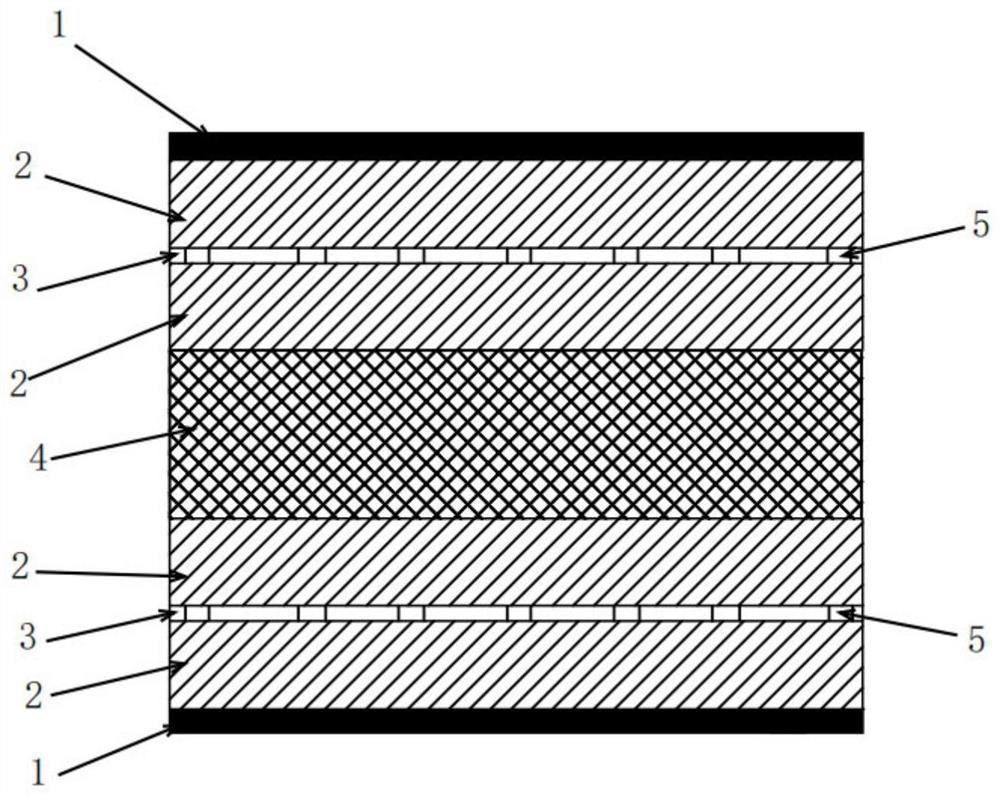

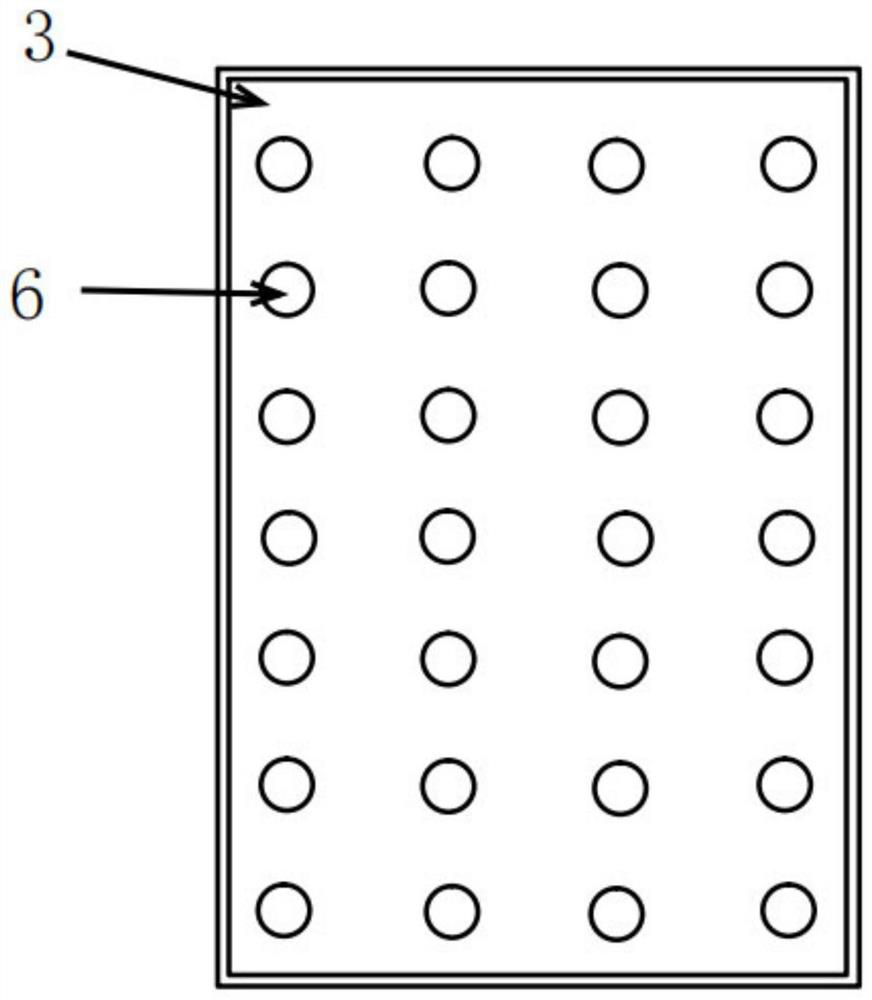

[0034] like figure 1 As shown, a low-temperature heat insulation panel for a refrigerated vehicle includes an outer heat insulation layer 1, the inner side of the heat insulation layer 1 is adhesively connected with an outer glued layer 2, and the inner side of the glued layer is connected with a metal layer 3 , the inner side of the metal layer 3 is connected to the inner glued layer 2, the inner side of the inner glued layer 2 is connected to the middle insulation layer 4 of the heat insulation board, and the whole heat insulation board is centered on the middle insulation layer 4, and the two outer sides are symmetrically arranged , the outermost layer of the insulation board is wrapped by a layer of PVC leather.

[0035] The temperature insulation layer 1 of the outer layer is a reinforced foam board covered with PEF on both sides, which has a good temperature insulation effect.

[0036] The glued layer 2 is arranged as the outer glued layer 2 between the metal layer 3 an...

Embodiment 2

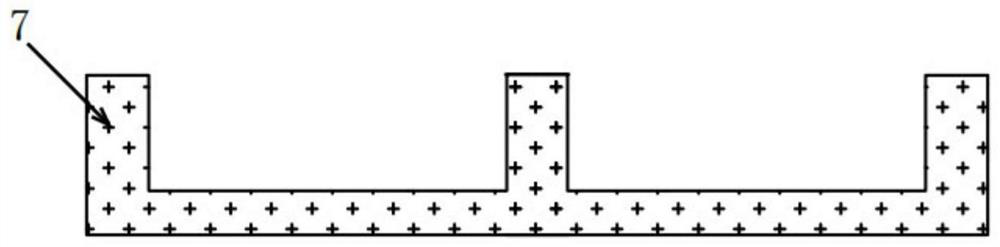

[0048] like Figure 4 As shown, the difference from Example 1 is that for the compartments of refrigerated vehicles with different temperature insulation requirements, the thermal insulation board can reserve the position of the waterproof fan during the synthesis process, so that the waterproof fan can be assembled on the thermal insulation board , so that the temperature in the refrigerated compartment can be adjusted.

[0049] The position of the temperature display can also be reserved on the heat insulation board, so that the temperature in the refrigerated car can be monitored in real time.

[0050] The other synthesis layers and synthesis process of the heat insulation board in the embodiment 2 are the same as the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com