Fading repair method suitable for yellowing of deacidified paper

A repair method and paper technology, which can be used in the post-processing of waste paper, and can solve problems such as yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

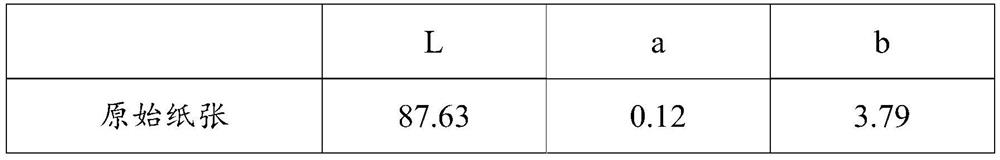

Embodiment 1

[0026] Select the machine-made paper that turns yellow 24 hours after deacidification, first remove the excess deacidification agent remaining on the surface of the paper with a weak acidic solution, choose a mixed solution of carbonic acid with a pH of 6.2 to 6.3 and 0.02mol / L sodium bicarbonate for the weak acidic solution , that is, continue to feed carbon dioxide gas into the 0.02mol / L sodium bicarbonate solution until the pH value of the solution is 6.2-6.3. After the prepared weak acidic solution is ultrasonically atomized, it is evenly applied to the surface of the yellowing paper. The atomization reaction time is 5 minutes. Dielectric barrier discharge, the discharge gas is a mixture of 5% hydrogen and 95% argon, the voltage is adjusted to 65V, and the current is 0.2A. When a stable discharge arc is generated in the plasma processing chamber, start timing and the yellowing The paper was taken out after being treated in the plasma treatment chamber for 60s, and the subs...

Embodiment 2

[0049] Select the machine-made paper that yellowing occurs in 24h after the same depickling as in Example 1, and the weakly acidic solution is adjusted to a mixed solution of carbonic acid and 0.005mol / L calcium bicarbonate in the process of Example 1, and the pH value of the solution is adjusted to 6.2 to 6.3, and the rest are the same as those in Example 1.

[0050] Performance Testing:

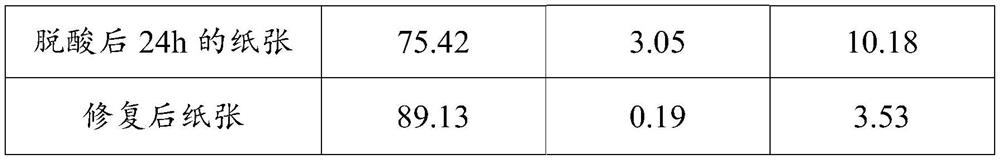

[0051] Take the machine-made paper before deacidification in Example 2, and measure the chromaticity value, and then take the machine-made paper 30 days after the fading and repairing, and carry out the measurement of the chromaticity value. The test method is the same as in Example 1. The test results are shown in Table 5. The color difference between the faded and repaired paper and the original paper meets the repair standard.

[0052] Table 5 The chromaticity value and its color difference with the original paper after 30 days of fading repair

[0053]

Embodiment 3

[0055] Select the same machine-made paper that turns yellow 24h after deacidification as in Example 1, adjust the hydrogen content in the hydrogen and argon mixture in the process of Example 1 to 8%, and the rest are the same as in Example 1. .

[0056] Performance Testing:

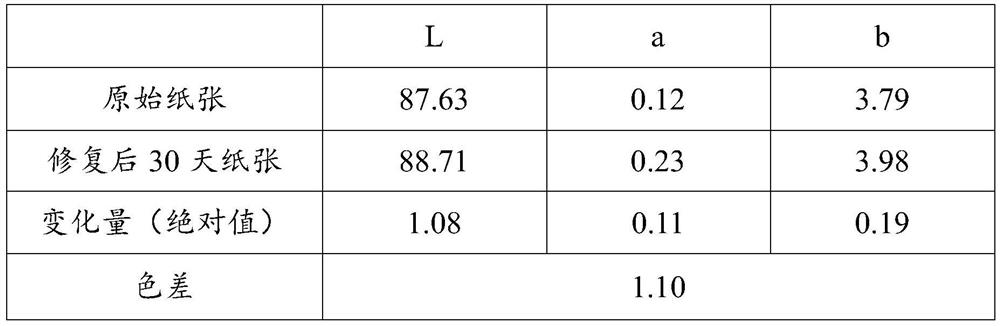

[0057] Take the machine-made paper before deacidification in Example 3, and carry out the measurement of chromaticity value, then take the machine-made paper 30 days after its fading and repairing, and carry out the measurement of chromaticity value, and the test method is the same as that of Example 1. The test results are shown in Table 6. The color difference between the faded and repaired paper and the original paper meets the repair standard.

[0058] Table 6 The chromaticity value and its color difference with the original paper after 30 days of fading repair

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com