Method for preparing photosensitive resin for solder mask ink

A technology of photosensitive resin and solder resist ink, which is applied in the direction of ink, photosensitive materials used in optomechanical equipment, applications, etc., can solve the problems of easy yellowing of photosensitive resin, reduce the reflectivity of light source, and high product scrap rate, so as to improve the hardness Good weather resistance, UV resistance, and the effect of reducing the content of benzene rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

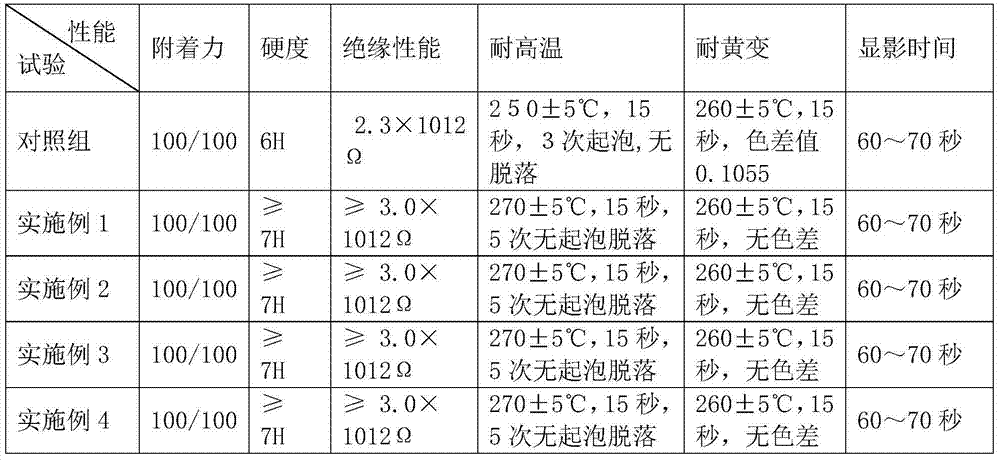

Examples

Embodiment 1

[0023] A preparation method of photosensitive resin for solder resist ink, comprising the following steps:

[0024] 1) Take 210 grams of o-cresol novolac epoxy resin (Tg=50-60) and 62.5 grams of DBE solvent into the reaction kettle, and dissolve at a temperature of 90-100 °C. Then take 74 grams of acrylic acid, 0.1 grams of hydroquinone, and 0.1 grams of tetraethylammonium bromide, mix them evenly, and add them dropwise into the reaction kettle at a temperature of 90-100°C, drop them in 2.5-3 hours, and then react After 2 hours, when the acid value was less than 5, the reaction was terminated to obtain prepolymer A.

[0025] 2) Take IPDI444g, PEG200196g. React at 80° until the NCO group content is less than 14.5%, to obtain prepolymer B.

[0026] 3) Take 200 grams of prepolymer B, add it to A, add 77.5 grams of tetramethylbenzene, 100 grams of DBE, and 0.2 grams of dibutyltin laurate as a catalyst. React at 90-100° until the NCO group content is less than 1%. After the rea...

Embodiment 2

[0028] 1) Take 210 grams of o-cresol novolac epoxy resin (Tg=50-60) and 62.5 grams of DBE solvent into the reaction kettle, and dissolve at a temperature of 95-100 °C. Then take 63 grams of acrylic acid, 0.1 grams of hydroquinone, and 0.1 grams of tetraethylammonium bromide, mix them evenly, and add them dropwise into the reaction kettle at a temperature of 90-100°C, drop them in 2.5-3 hours, and then react React for 2 hours, when the acid value is less than 5, the reaction ends and prepolymer A is obtained.

[0029] 2) Take HDI336.16 grams, PEG-1000390 grams. React at 80° until the NCO content is less than 12.4%, to obtain prepolymer B.

[0030] 3) Take 240 grams of prepolymer B, add it to A, add 94.7 grams of tetramethylbenzene, 100 grams of DBE, and 0.2 grams of dibutyltin laurate as a catalyst. React at 90-100° until NCO% is less than 1%. After the reaction, take 76 grams of hexahydrophthalic anhydride and keep it warm at 100-105° until the acid value is 50mgKOH / g-54mgK...

Embodiment 3

[0032] 1) Take 210 grams of o-cresol novolac epoxy resin (Tg=50-60) and 62.5 grams of DBE solvent into the reaction kettle, and dissolve at a temperature of 90-100 °C. Take 105 grams of acrylic acid, 0.1 grams of hydroquinone, and 0.1 grams of tetraethylammonium bromide, mix them evenly, and add them dropwise into the reaction kettle at a temperature of 90-100 ° C. After 2.5-3 hours, the reaction is continued. React for 2 hours, when the acid value is less than 5, the reaction ends and prepolymer A is obtained.

[0033] 2) Take 444 grams of IPDI and 196 grams of PEG-200. React at 80° until the NCO content is less than 14.5%, to obtain prepolymer B.

[0034] 3) Take 200 grams of prepolymer B, add it to A, add 77.5 grams of tetramethylbenzene, 102.6 grams of DBE, and 0.2 grams of dibutyltin laurate as a catalyst. React at 90-100° until NCO% is less than 1%. After the reaction, take 76 grams of hexahydrophthalic anhydride and keep it warm at 100-105° until the acid value is be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com