Online cleaning machine for automobile exhaust treatment system

A technology for processing system and automobile exhaust, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of time-consuming, manpower, low degree of automation, inconvenient operation, etc., to avoid waste, high economic value, and easy operation Convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

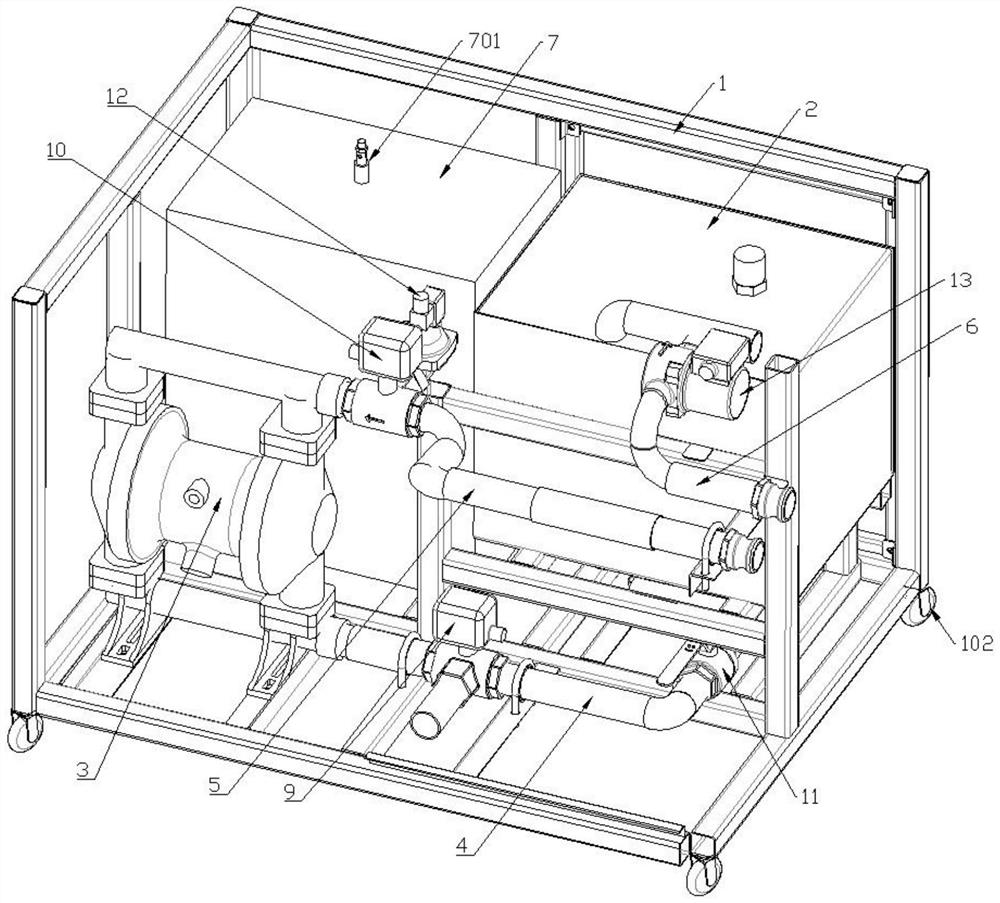

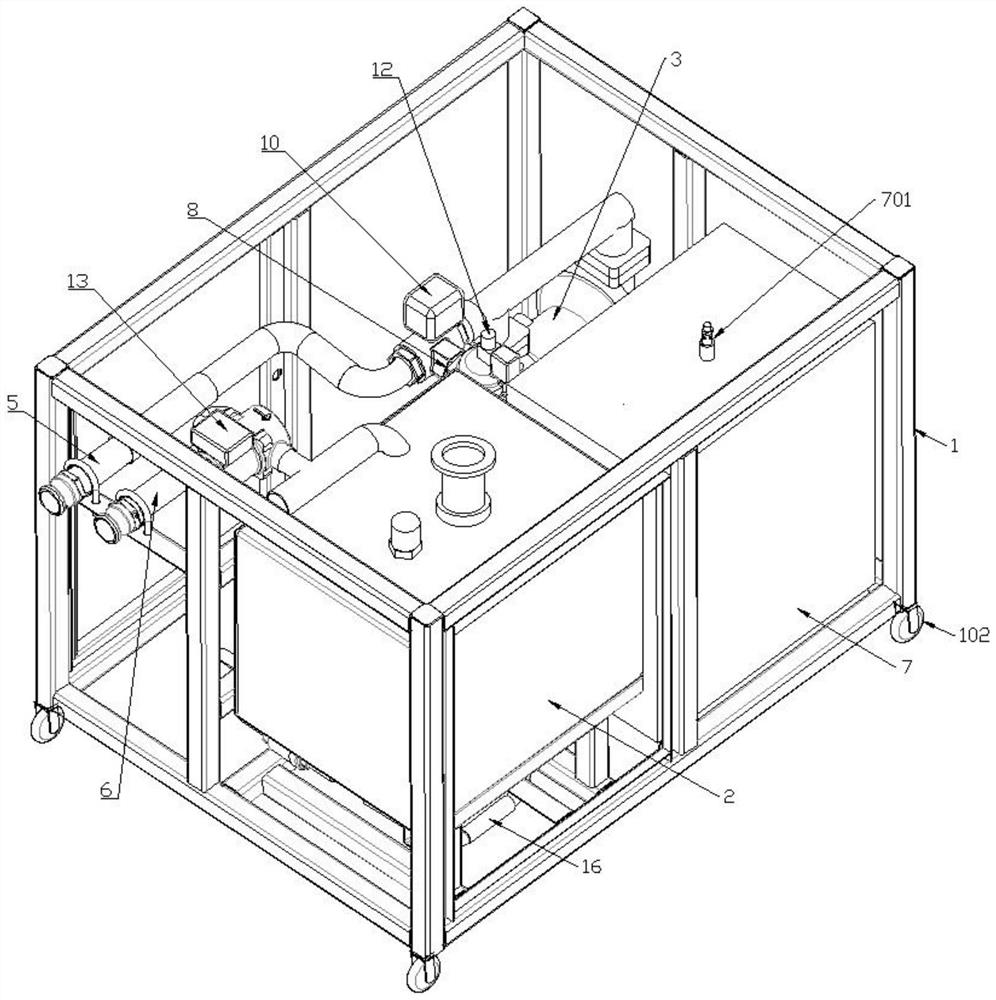

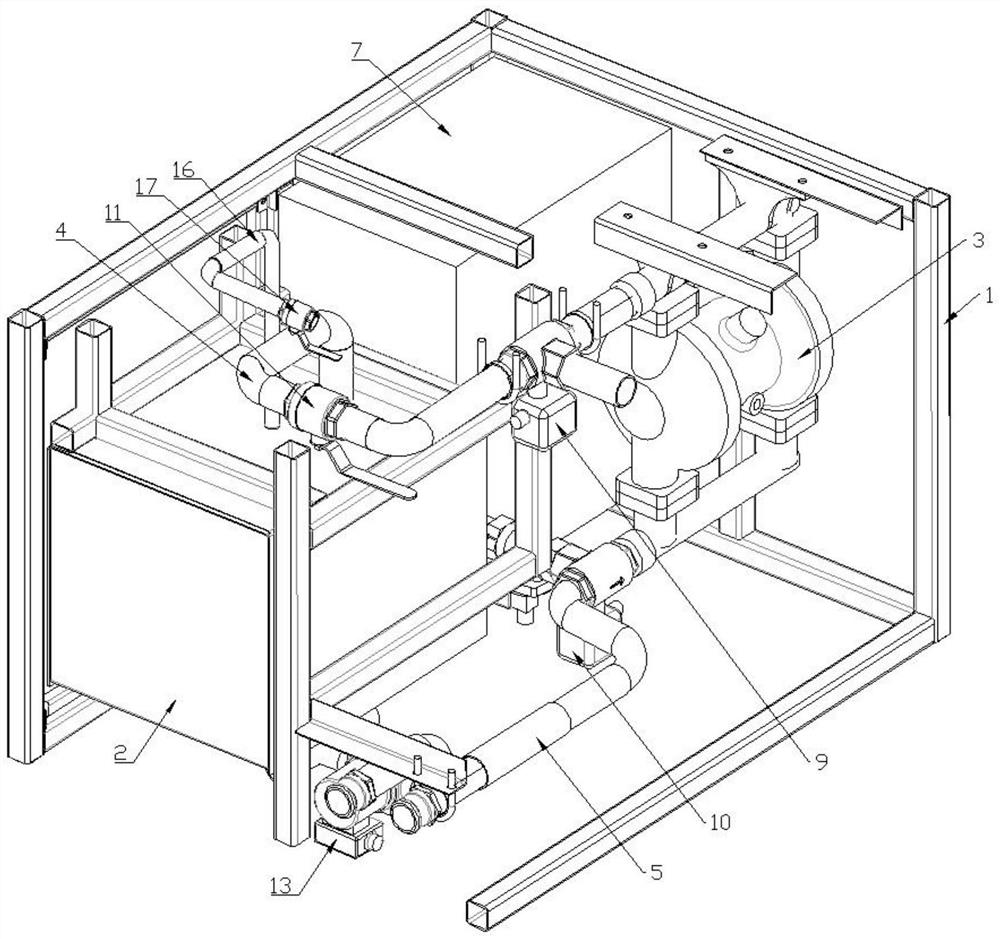

[0030] Such as Figure 1-Figure 8 Shown:

[0031] The invention provides an online cleaning machine for automobile exhaust treatment system, which comprises a fixed frame 1, a liquid storage tank 2 and a pneumatic diaphragm pump 3, the liquid storage tank 2 and the pneumatic diaphragm pump 3 are installed inside the fixed frame 1, the liquid storage tank 2 and the pneumatic A first liquid outlet pipeline 4 is provided between the diaphragm pumps 3, a second liquid outlet pipeline 5 is provided between the pneumatic diaphragm pump 3 and the exhaust gas treatment system, and a liquid return pipeline 6 is provided between the exhaust gas treatment system and the liquid storage tank 2.

[0032] Specifically, the fixed frame 1 is a square skeleton structure, the four corners of the bottom are provided with rollers 102 for easy movement, and a handle 101 is connected to one side for the operator to control, push or stop. The sides of the fixed frame 1 are covered with cover plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com