Meat puree processing mechanism, pork puree production line, and production method

A technology of processing mechanism and meat puree, which is applied in the direction of processing meat, meat processing equipment, metal processing, etc., can solve the problems of hindered working accuracy of the hammer head, inability to cut, unfavorable for industrial production and streamlined production, etc., to improve convenience, Reduces the effect of manipulating the point of the power source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

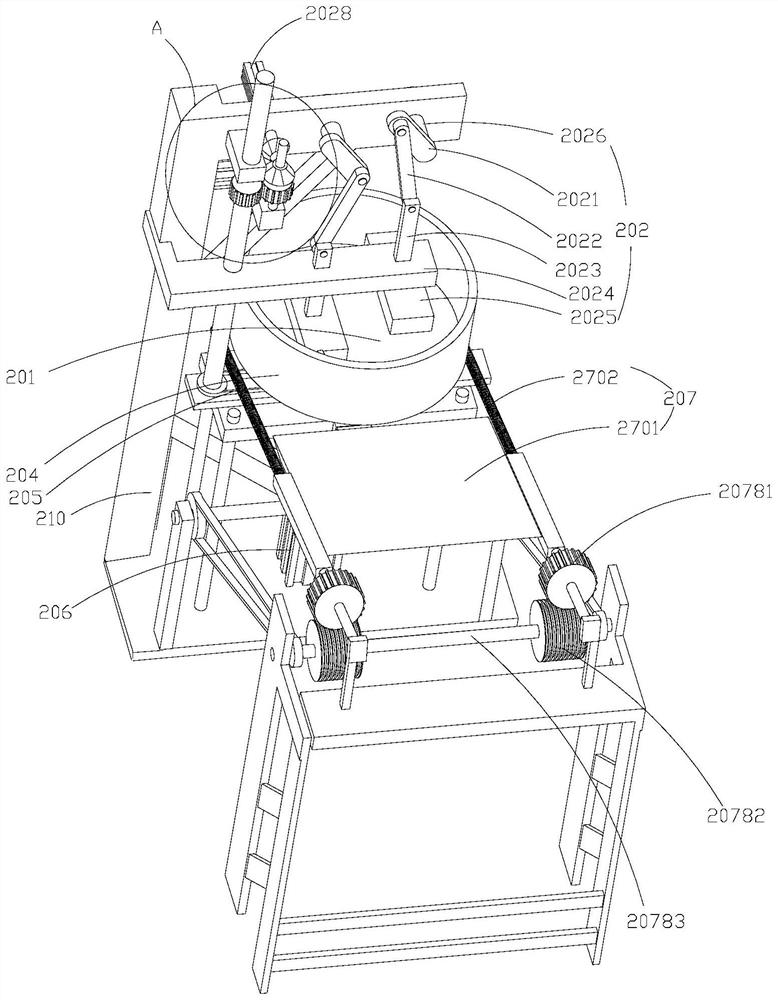

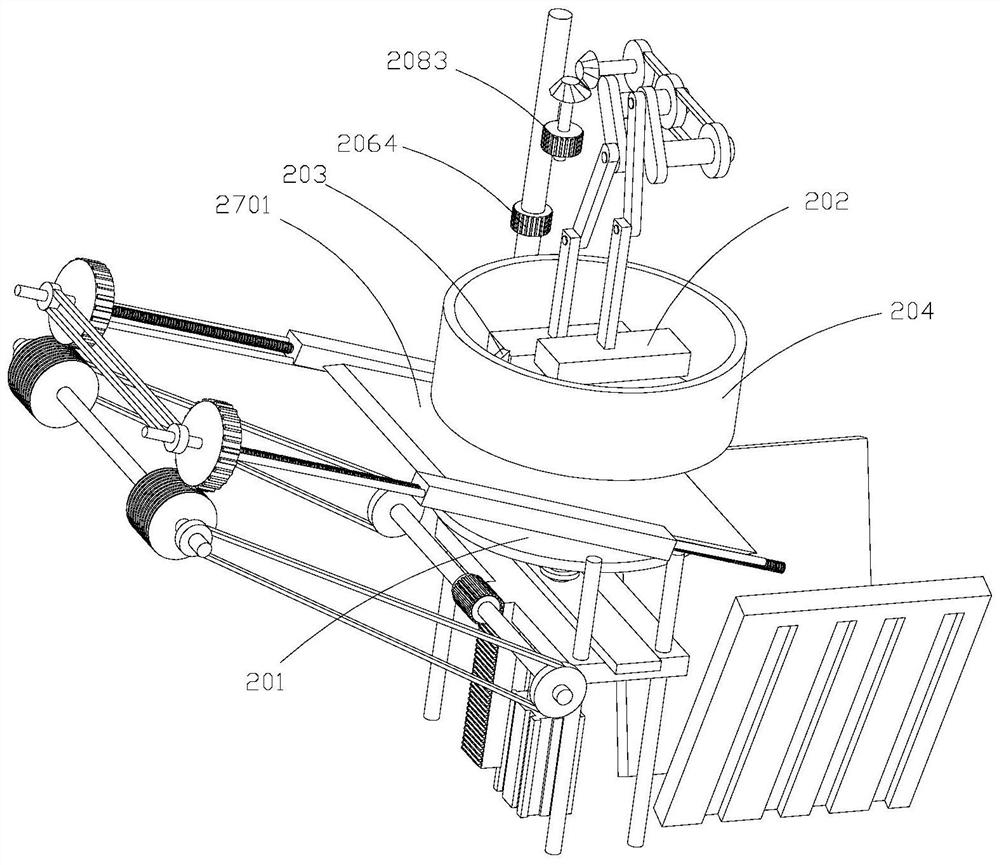

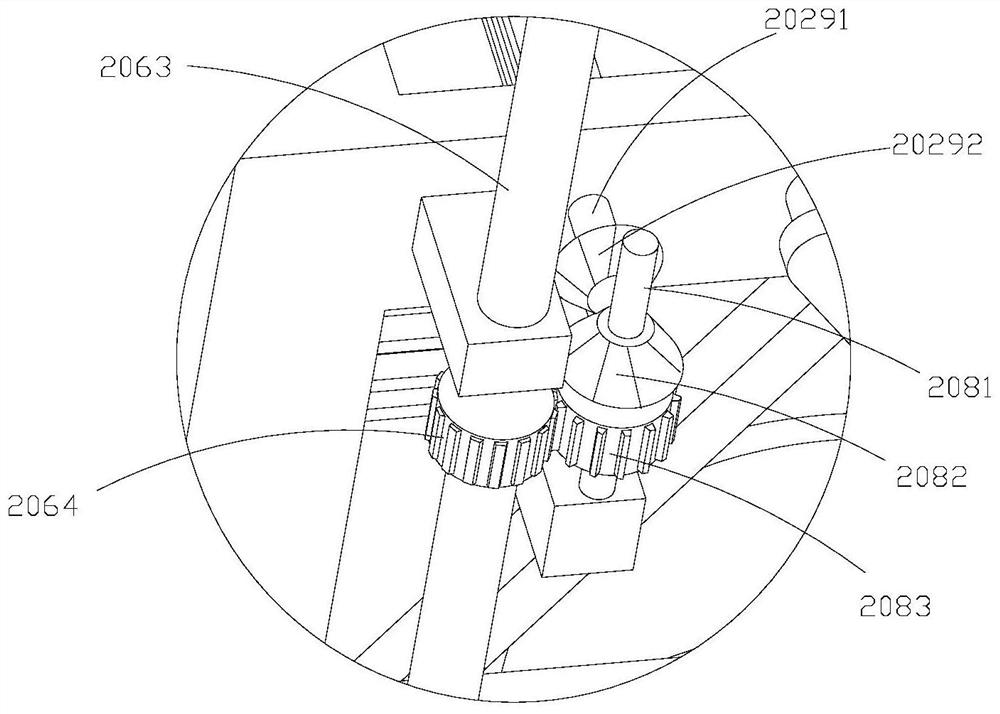

[0063] like Figure 1-3 As shown in the figure, this embodiment discloses a meat puree processing mechanism based on the separation and sedimentation of the meat beater, which includes a meat beater 201, a beating device 202, a turning plate 203, a surrounding plate 204, a rotating device 205, a lifting device 206, a pusher Unloading device 207. The beating device 202 is used for beating the meat pieces on the meat beating plate 201 . The flap 203 is arranged on the inner wall of the enclosure plate 204 . The upward movement of the lifting device 206 drives the rotating device 205 to rise until the outer peripheral surface of the meat-beating plate 201 contacts the inner peripheral wall of the enclosure plate 204 . The downward movement of the lifting device 206 drives the rotating device 205 to descend until the meat-beating plate 201 is separated from the hoarding plate 204 downward, and the pushing plate 2071 of the pushing and unloading device 207 moves toward the positi...

Embodiment 2

[0092] The present embodiment discloses a pork puree production line based on the meat puree processing mechanism for separating and sedimenting the meat by the above-mentioned meat beater. Clay processing agency. The meat pieces cut by the pork dicing device are fed to the meat puree processing mechanism where the meat plate is separated and sedimented for beating.

[0093] like Figure 13-15As shown, the pork dicing device includes a dicing table 101, a meat setting plate 102, a vertical knife plate 103, an extension mechanism 104, a top plate 105, a sliding block 106, a reverse transmission mechanism 107, an elastic reset device 108, and a connecting plate 109. The cutting table 101 is provided with a moving guide groove 1011 for the meat setting plate 1011, which is guided up and down in the same direction as the moving direction of the meat setting plate 102. The elastic reset device 108 is assembled so that the meat setting plate 102 is inclined. The lower end is clos...

Embodiment 3

[0126] The present embodiment discloses a method for processing pork puree, comprising the following steps:

[0127] Step 1. Cut the fresh pork into pieces after acceptance;

[0128] Step 2: Beat the cut pork pieces and add accessories;

[0129] The mashed meat obtained in step 3 and step 2 is packed and electronically weighed; wherein the sealing temperature during packing is 120-140°C;

[0130] Step 4: Quick-freeze the mashed meat in the quick-freezing refrigerator;

[0131] Step 5: Manual packing;

[0132] Step 6. Freeze the finished product in the refrigerator at a temperature below -18°C.

[0133] Preferably, the packaging material used for packaging in step 3 is sterilized by ultraviolet light, and the sterilization time is 30 minutes.

[0134] The meat puree in step 4 passes through the maximum ice crystal formation zone within 30 minutes under the environment of -30°C to -40°C, the central temperature of the meat puree drops from -1°C to -5°C, and the formed ice cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com