Oily air filtering material as well as preparation method and application thereof

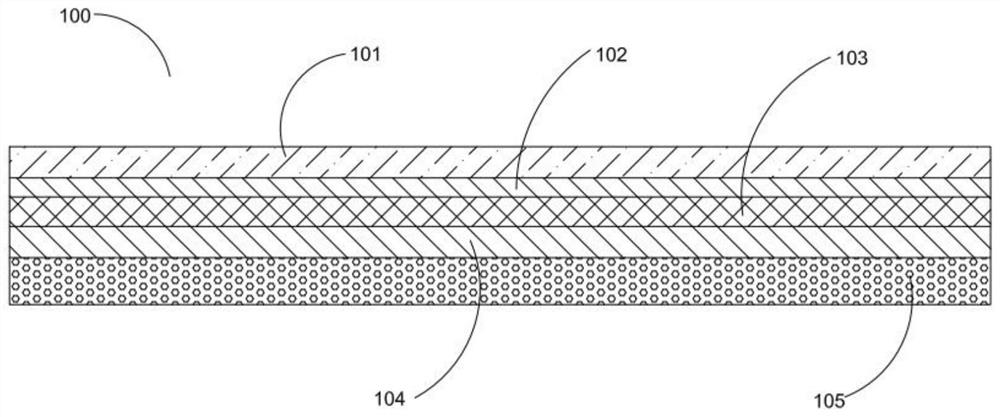

An air filter material and oil-based technology, applied in the field of oil-based air filter material and its preparation, can solve the problems of low filtering oily particles, low filtering efficiency, short service life, etc., and achieve low air resistance, increase dust holding capacity, and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

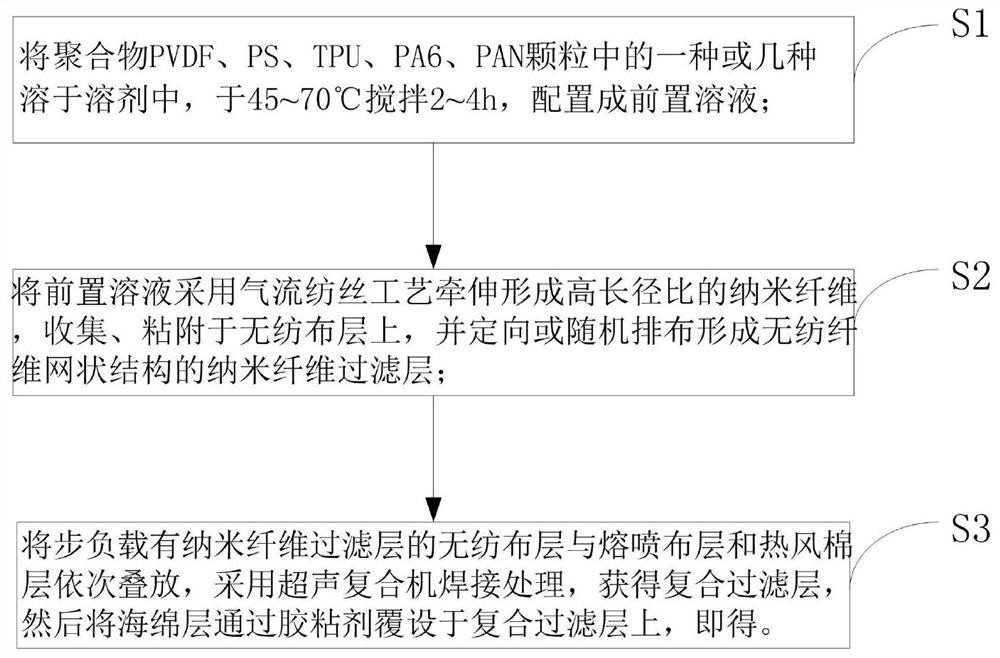

[0038] The present invention also provides a method for preparing the oily air filter material as described above. The preparation process of the oily air filter material is relatively simple, and the prepared oily air filter material has high dust holding capacity, high filtration efficiency, and low air filtration resistance. And the advantage of being able to regenerate and reuse it many times. Such as figure 2 Shown, its preparation method specifically comprises the following steps:

[0039](1) Prepare the pre-solution: dissolve one or more of the polymer PVDF, PS, TPU, PA6, and PAN particles in the solvent, stir at 45-70°C for 2-4 hours, and prepare the pre-solution;

[0040] (2) Solution method air spinning: the pre-solution configured in step (1) is drafted by solution method air spinning process to form nanofibers with high aspect ratio, collected, adhered to the non-woven fabric layer, and oriented Or a nanofiber filter layer randomly arranged to form a non-woven f...

Embodiment 1

[0048] Provide an oily air filter material, the non-woven layer adopts 15g / m 2 PP spun-bonded non-woven fabric, the melt-blown cloth layer adopts melt-blown cloth with a filtration efficiency of 85%, and the hot-air cotton layer adopts 30g / m 2 The hot air cotton, the sponge layer adopts 20g / m 2 ordinary sponge. Specifically, its preparation method includes the following steps:

[0049] (1) Configure the pre-solution: add an appropriate amount of PAN powder into the DMF solvent, keep stirring at 60°C for 4 hours, and finally obtain a pre-solution of 13% PAN;

[0050] (2) Solution method air spinning: place the non-woven fabric layer on the collector, set the collection distance to 20cm, the wind force to 280m / min, and the single needle liquid supply speed to 2.0ml / h. The solution is drawn by the solution method air spinning process to form nanofibers with high aspect ratio, collected and adhered to the non-woven fabric layer, and oriented or randomly arranged to form a nanof...

Embodiment 2

[0055] Provide an oily air filter material, the non-woven layer adopts 15g / m 2 PP spunbonded non-woven fabric, the melt-blown cloth layer adopts melt-blown cloth with a filtration efficiency of 65%, and the hot-air cotton layer adopts 40g / m 2 The hot air cotton, the sponge layer adopts 40g / m 2 ordinary sponge. Specifically, its preparation method includes the following steps:

[0056] (1) Configure the pre-solution: add an appropriate amount of PVDF powder into the DMF solvent, keep stirring at 55°C for 4 hours, and prepare the pre-solution of 16% PVDF;

[0057] (2) Solution method air spinning: place the non-woven fabric layer on the collector, set the collection distance to 20cm, the wind force to 350m / min, and the single-needle liquid supply speed to 2.0ml / h. The solution is drawn by the solution method air spinning process to form nanofibers with high aspect ratio, collected and adhered to the non-woven fabric layer, and oriented or randomly arranged to form a nanofiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com