Aluminum alloy profile machining device

An aluminum alloy profile and processing device technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of high labor intensity, inability to process at multiple angles, low work efficiency, etc., to reduce labor intensity and improve. Work efficiency, high work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

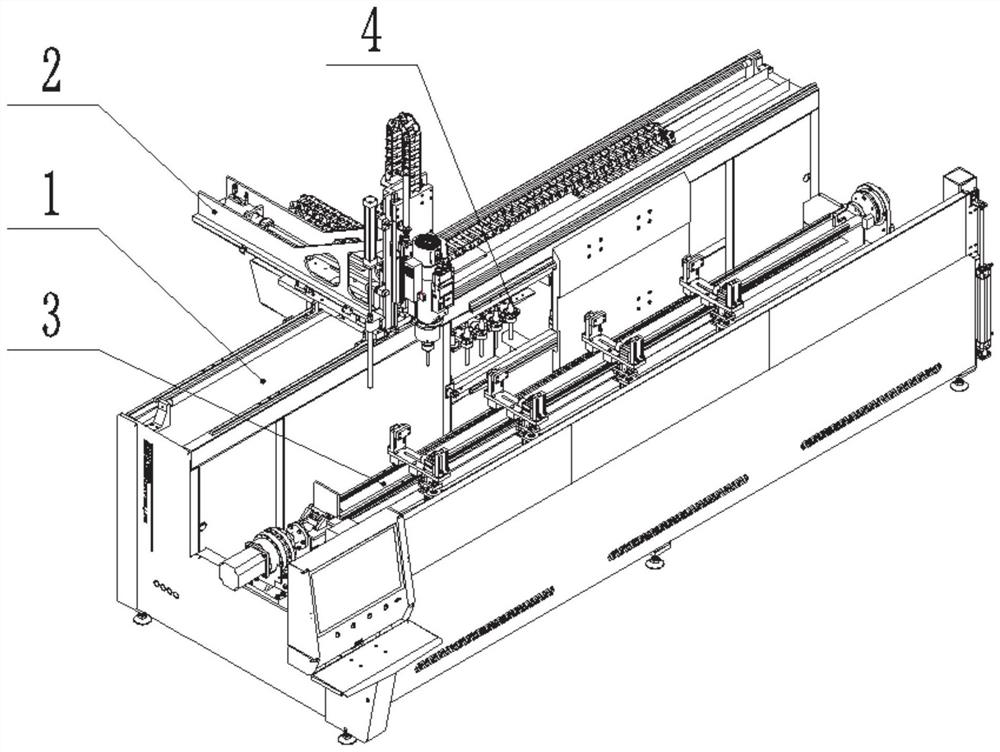

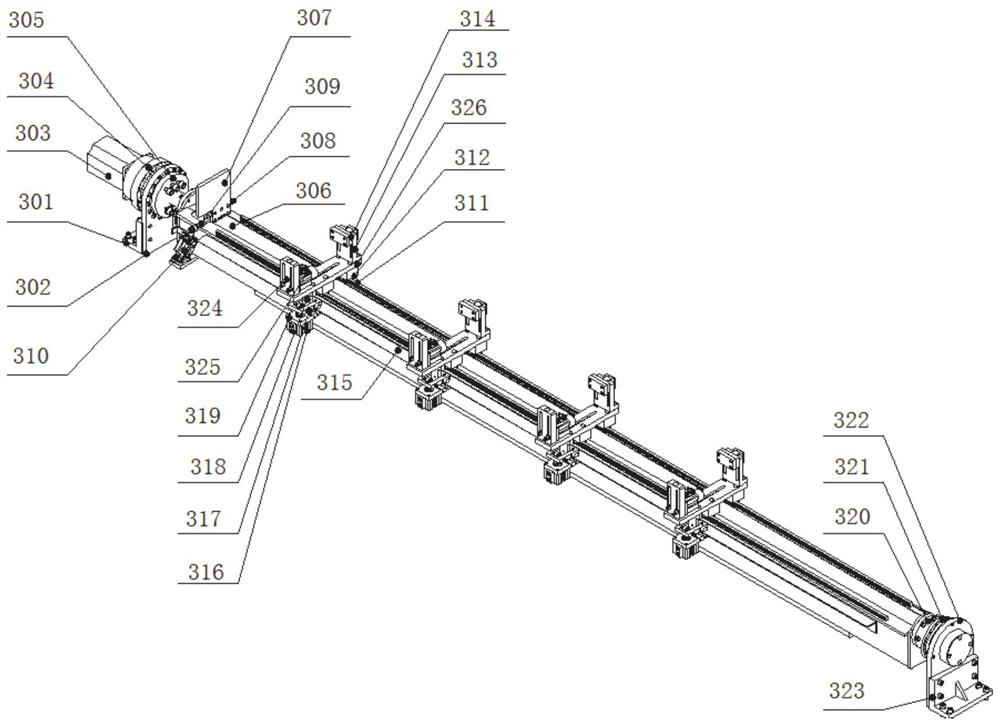

[0032] An aluminum alloy profile processing device, such as figure 1 As shown, it includes a frame 1, the frame is equipped with a machine head 2, a workbench 3 is arranged on one side of the machine head, and a plurality of clamping mechanisms for fixing profiles are arranged on the workbench. In this embodiment, the definition The direction along the length of the entire processing device in the horizontal plane is the first direction, and the direction perpendicular to the first direction is the second direction. The machine head is provided with a cutter, which can move along the first direction, the second direction and the vertical direction, and process the profile workpiece arranged on the workbench.

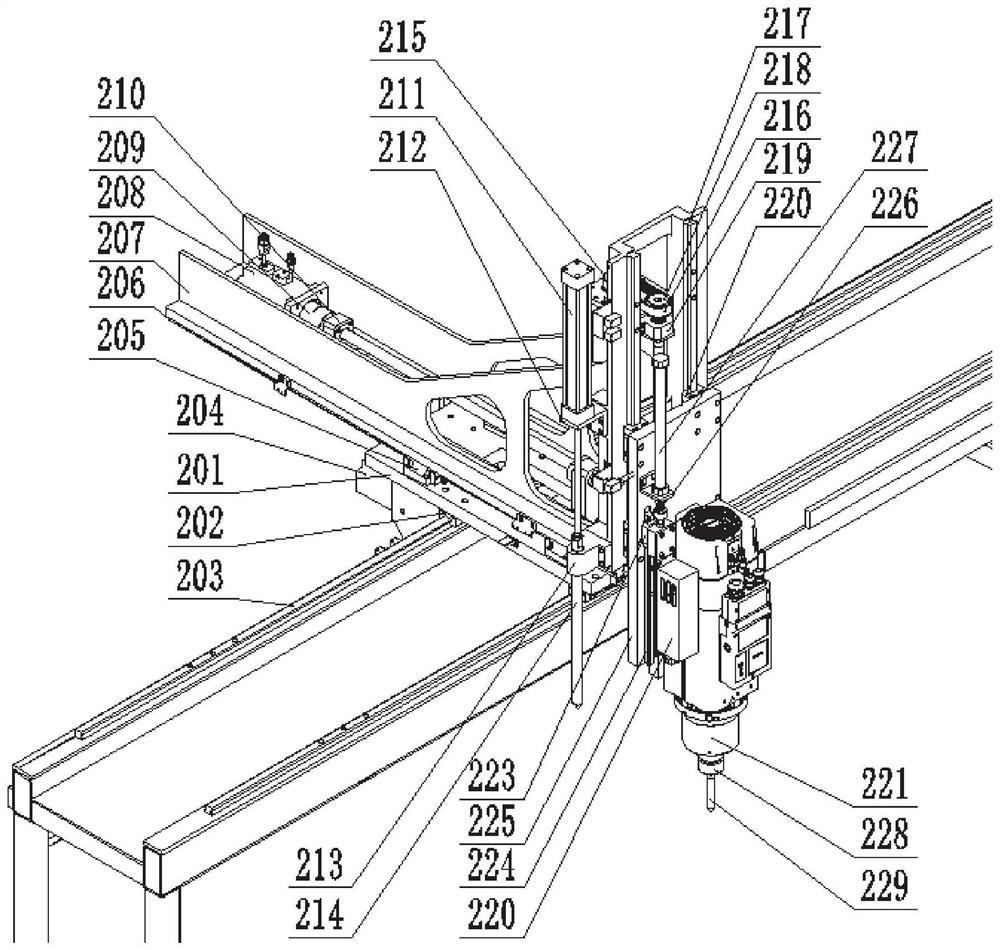

[0033] The machine head includes a two-axis linkage mechanism installed on the frame. The two-axis linkage mechanism is connected to the vertical drive mechanism and can drive the vertical drive mechanism to move in the first direction or the second direction. The vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com