Novel tunnel construction ventilation system based on high-pressure air supply and ventilation method thereof

A ventilation system and high-pressure air technology, applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve problems such as lagging construction progress and insufficient air supply, and achieve smooth inner walls, reduced land occupation, and durability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

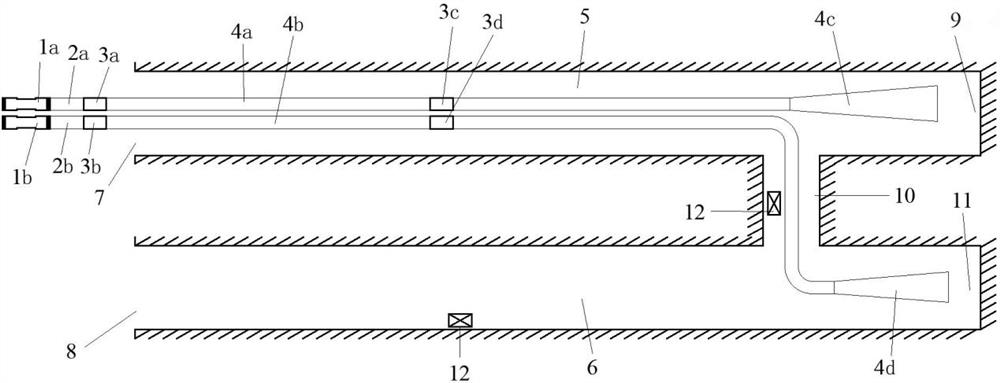

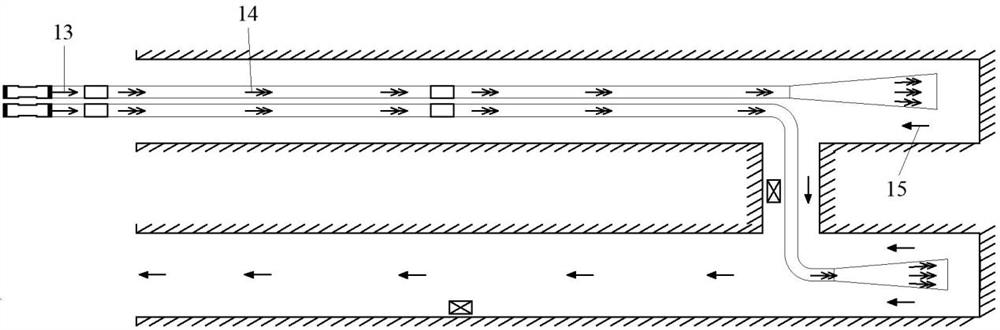

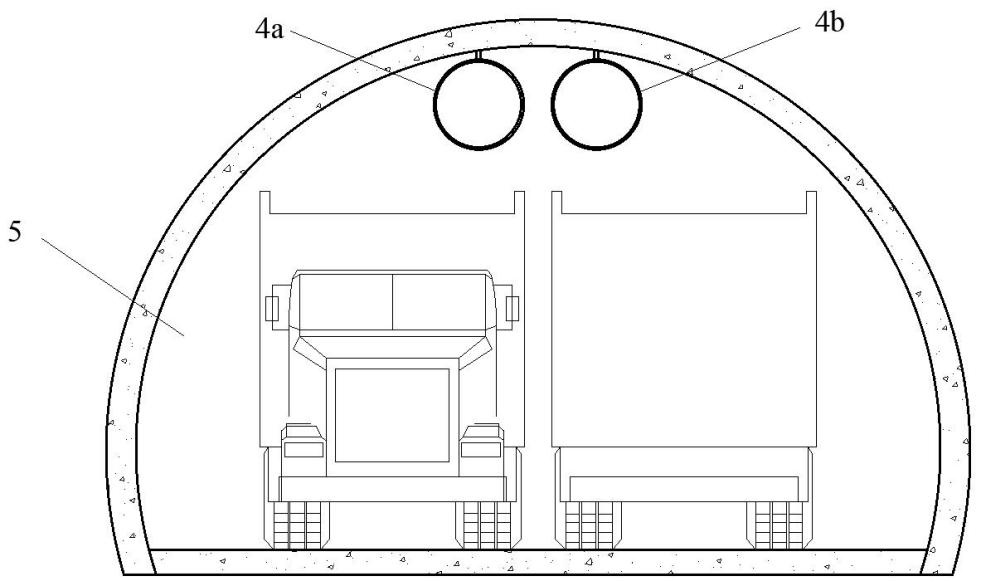

[0052] Combine Figure 1 to 3 As shown, this embodiment provides a new tunnel construction ventilation system based on high pressure air supply, which is applied to small section tunnels, including tunnel right-line forward hole inlet 8, auxiliary transverse passage 10 and through auxiliary cross channel 10 The tunnel left-line positive or parallel guiding hole of the tunnel right-line front hole inlet 8 is connected, and the present embodiment is an example; in particular, the ventilation system of the present embodiment includes a power supply power system and a gas stream delivery system for supply The wind power system is disposed at the entrance of the tunnel. The air supply power system is disposed at the inlet of parallel guiding cavity 7, and the airflow power system is used to form a high-speed airflow; the airflow delivery system is disposed within the tunnel hole and can be transported in network transportation The form extends to the tunnel inlet and the supply power sy...

Embodiment 2

[0065] Embodiment 2 is the same as that of the examples, and the difference is: bonding Figure 1 to 3 As shown, the present embodiment also provides a new tunnel construction ventilation system based on high pressure air supply wind, on the basis of the first example, the ventilation system of the present embodiment includes a secondary pressurization system, a secondary pressurization system The air booster pump three 3c disposed in the first high pressure transport section 4a and the air boost pump disposed in the second high pressure transport section 4b, the air boost pump three 3C is used to the first high pressure transport section 4A The high pressure new wind 14 is again pressurized, and the air boost pump four 3D is used to increase the high-pressure new wind 14 in the second high pressure transport section 4b, whereby the secondary pressurization system is used to enter the airflow delivery system. The airflow is used for twice or more. To avoid the high frequency arrang...

Embodiment 3

[0113] Example III is basically the same as in Example 2, and the difference is: binding Figure 1 to 3 as well as Figure 5 As shown, this embodiment provides a new tunnel construction ventilation system based on high pressure air supply wind, on the basis of the second embodiment, the airflow diffusion section of the ventilation system of the present embodiment is arranged in the air flow diffusion section of the present embodiment. The vent hole 25, in the illustrated embodiment, the outer profile surface of the gradient diameter high pressure hard duct A and the gradient diameter high pressure rigid duct B is uniformly arranged with a vent hole 25 for carrying out high pressure gases of the end. Diversion processing;

[0114] Combine Figure 1 to 3 as well as Figure 5 As shown, the present invention also provides a ventilation method using the new type of tunnel construction ventilation system based on high pressure air supply wind, including the following steps:

[0115] S1, ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com