A Method for Accelerating Failure and Corrosion of Organic Coating/Metal Systems

An organic coating and metal technology, applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve problems that cannot fully meet the corrosion failure of organic coating/metal systems, and achieve simple and operable methods Strong, accelerated failure and corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

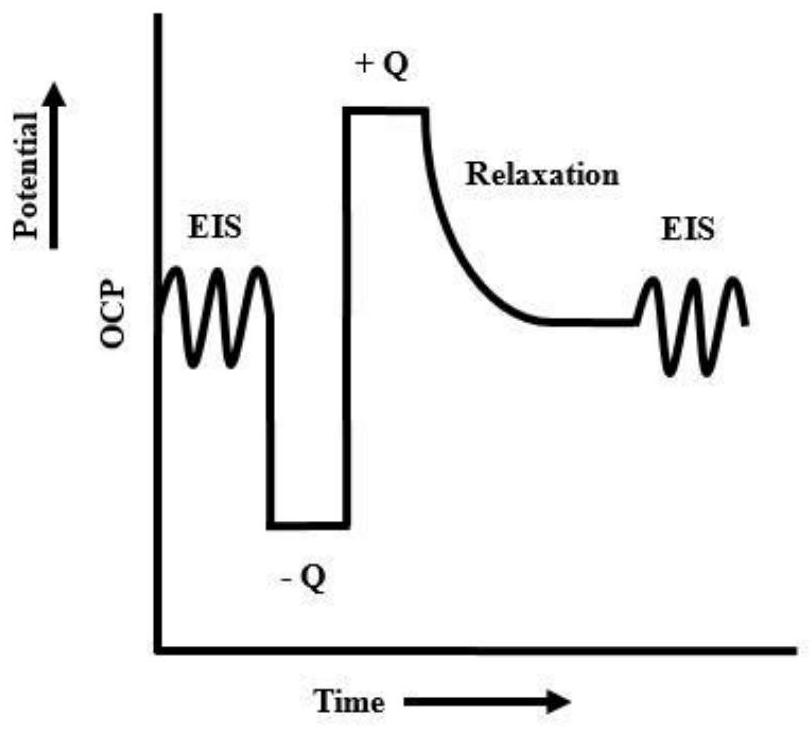

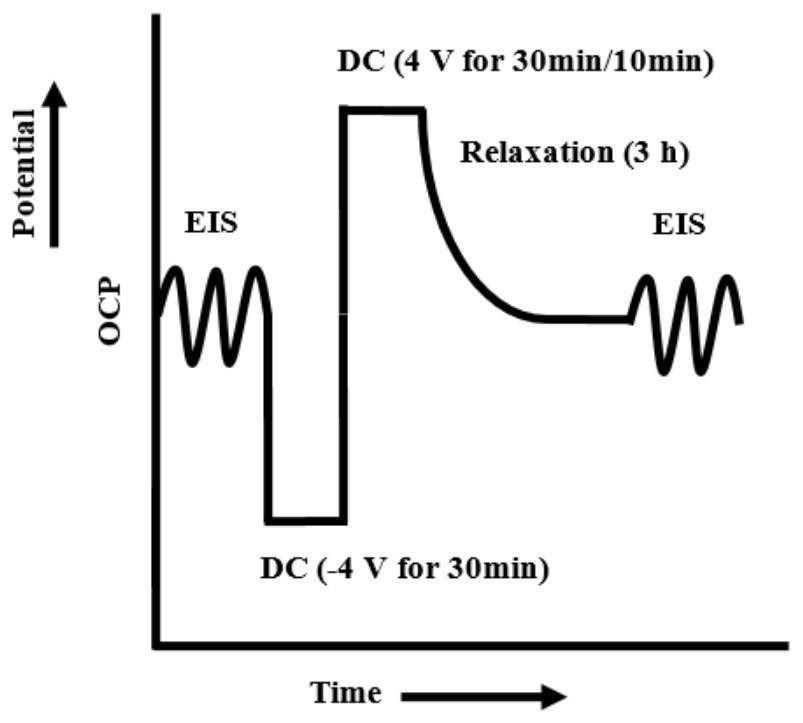

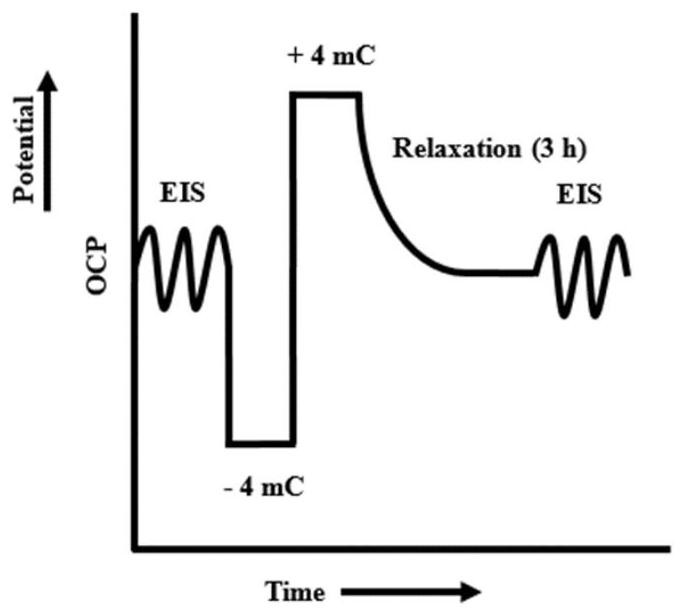

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, a kind of test procedure and test result of the method for accelerating organic coating / metal system failure and corrosion of the present invention are described in detail as follows:

[0042] Taking the epoxy electrophoretic paint coating / carbon steel sample as the test object, taking 3.5% sodium chloride solution as the test medium, carry out the immersion test respectively, adopt the equal electric cathode and anode alternation method of the present invention to carry out the accelerated test, adopt the prior art The accelerated test was carried out by the equipotential cathodic and anode alternation method. specifically:

[0043] In a pair of proportions, the electrochemical AC impedance was measured every 240 hours in the immersion test. Use the electrochemical workstation to carry out the electrochemical impedance spectroscopy test on the sample. The test uses a three-electrode electrolytic cell, wherein the referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com